Preparation method of ferrum-titanium-manganese ternary compound arsenic removal adsorbent

A ternary composite, adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing water treatment costs and increasing the complexity of water treatment operations, etc. To achieve the effect of good removal performance, excellent water purification performance, and environmentally friendly materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

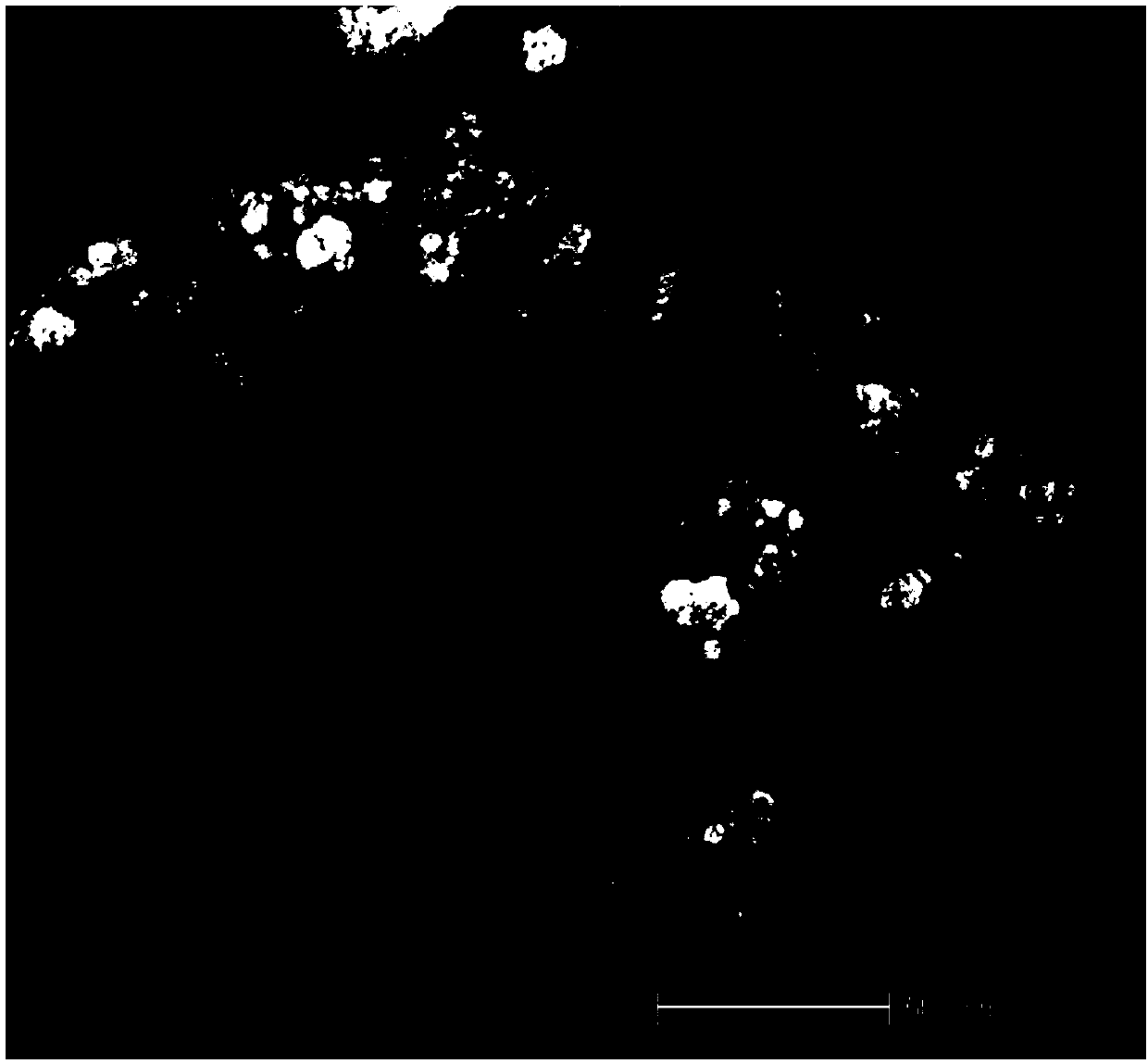

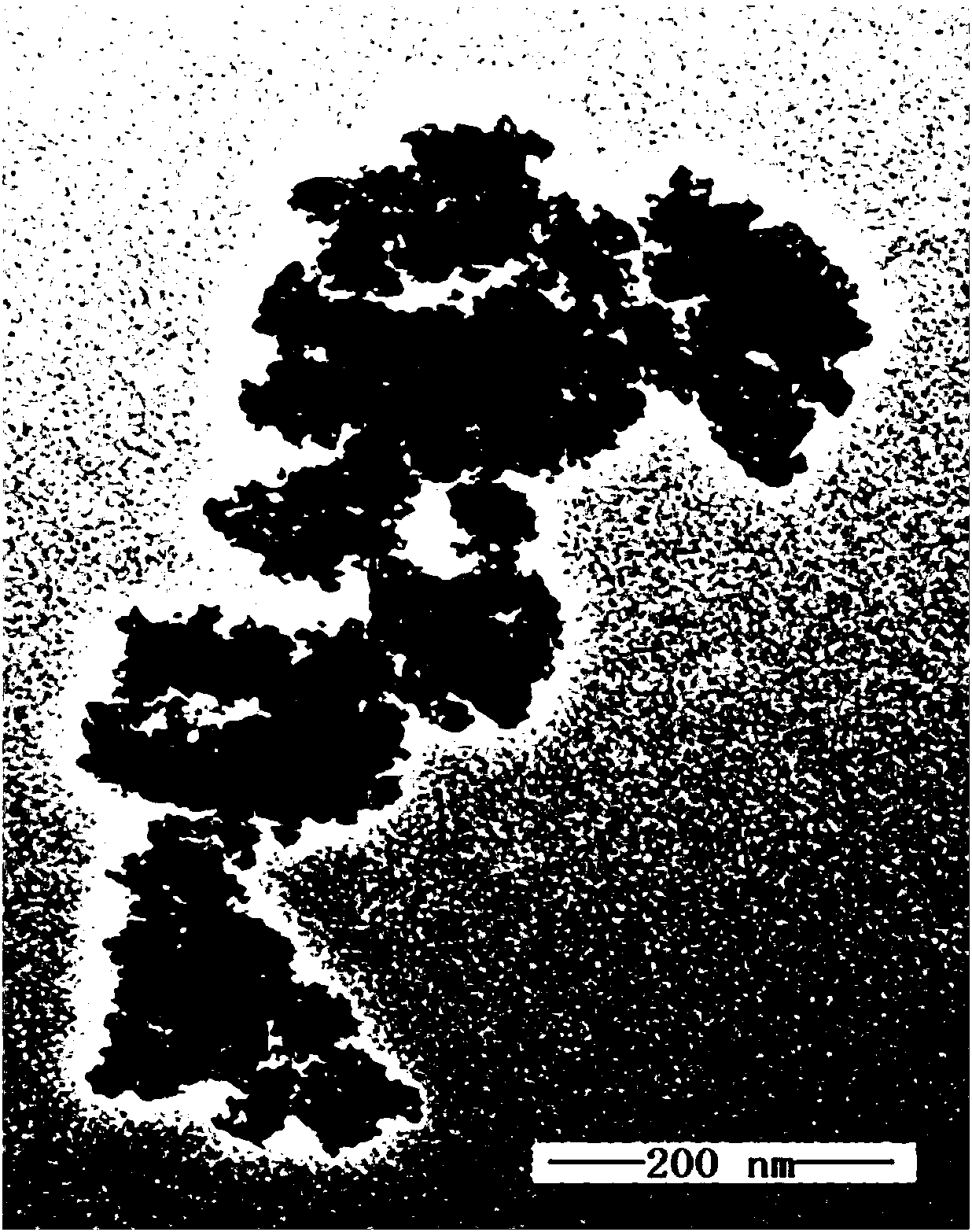

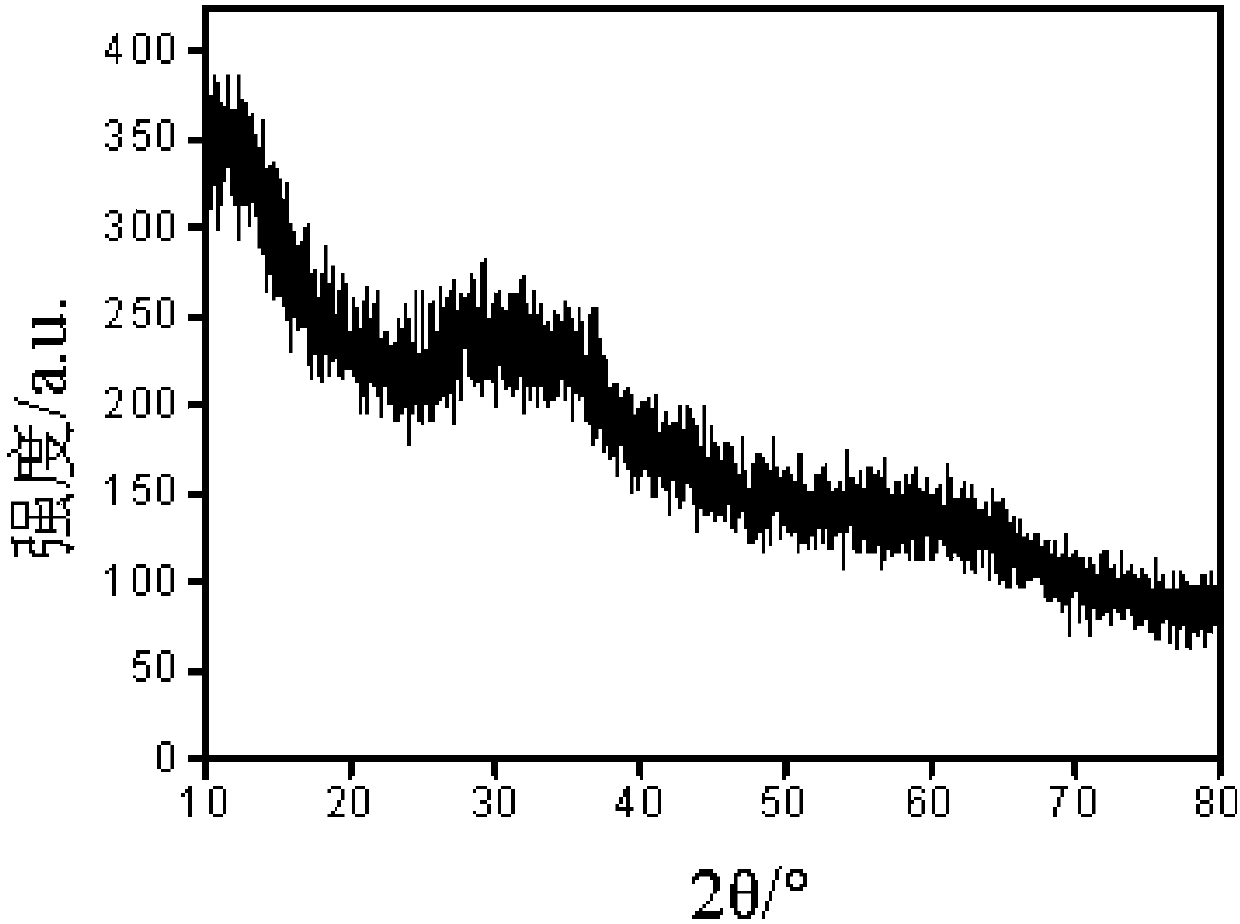

[0030] Specific implementation mode 1: This implementation mode is a preparation method of an iron-titanium-manganese ternary composite arsenic removal adsorbent, which is specifically carried out according to the following steps:

[0031] Dissolve iron salt, titanium salt and manganese salt in water and mix to obtain mixed solution A; dissolve soluble permanganate and alkaline compound in water and mix together to obtain mixed solution B; add mixed solution B to mixed solution A , to obtain a mixed solution C with a pH of 5-9, continue to stir the mixed solution C for 5min-4h, then age for 1h-12h, discard the supernatant, keep the lower precipitate, wash the precipitate with water until no anions are detected in the lotion , suction-filtering the washed precipitate to obtain a filter cake, and then drying the filter cake at a temperature of 25° C. to 100° C. to obtain an iron-titanium-manganese ternary composite adsorbent for removing arsenic;

[0032] In this embodiment, the...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment differs from Embodiment 1 in that the soluble ferrous salt is one or a mixture of ferrous chloride and ferrous sulfate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the soluble titanous salt is one or a mixture of titanous chloride and titanous sulfate. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com