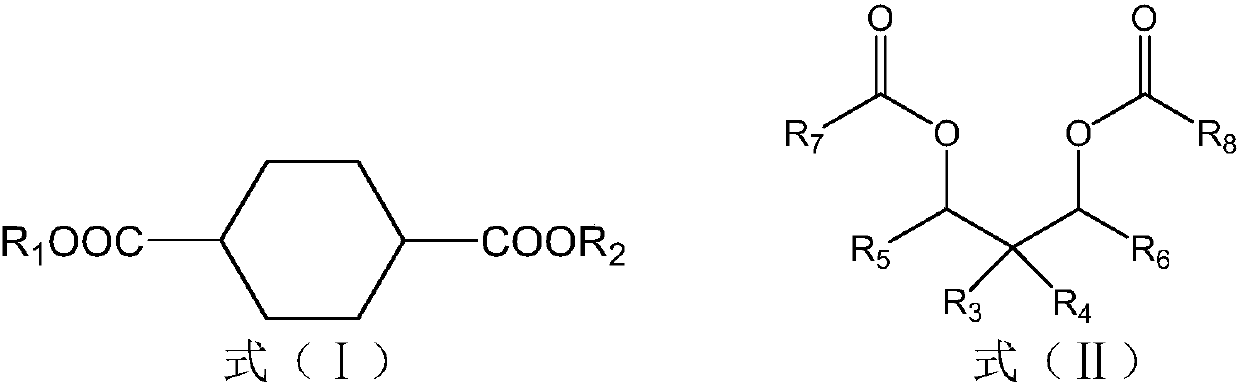

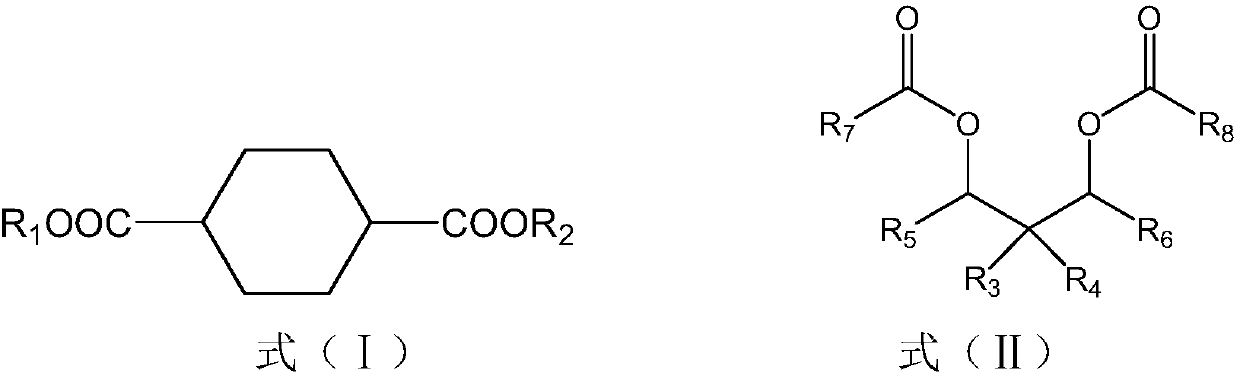

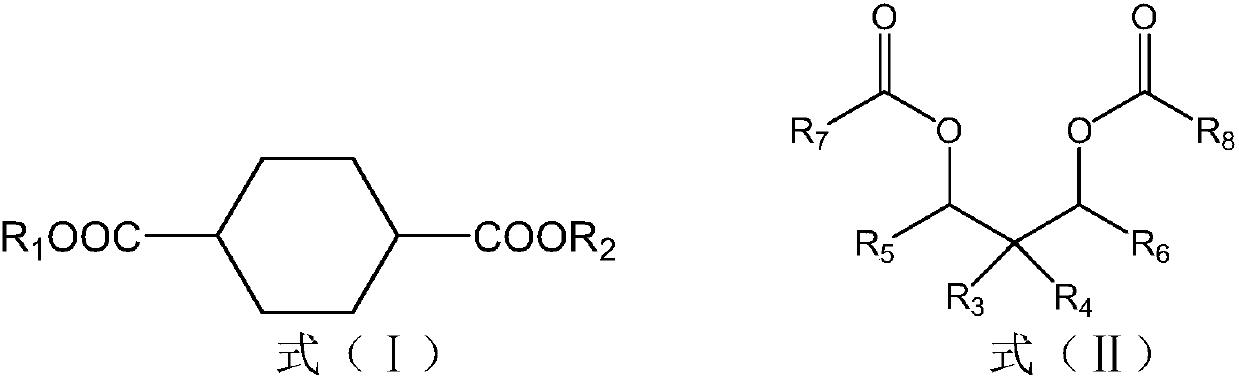

Solid catalyst component, catalyst system and prepolymerization catalyst for olefin polymerization

A solid catalyst and olefin polymerization technology, applied in the field of olefin polymerization catalysts, can solve the problems of limited application range, narrow polymer molecular weight distribution, unsatisfactory toughness and processing performance, etc., and achieve improved polymerization activity, excellent comprehensive performance, instant The effect of high regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to one embodiment, the solid catalyst component comprises a reaction product of a magnesium compound, a titanium compound and the internal electron donor compound, wherein the molar ratio of the magnesium compound, the titanium compound and the internal electron donor compound can be 1:( 0.5~150): (0.02~0.5).

[0036] Wherein, the magnesium compound can be selected from magnesium dihalide, alkoxy magnesium, alkyl magnesium, hydrate or alcoholate of magnesium dihalide, and a halogen atom in the molecular formula of magnesium dihalide replaced by alkoxy or haloalkoxy At least one of the derivatives substituted by the group.

[0037] Preferably, the magnesium compound is a magnesium dihalide and / or an alcoholate of magnesium dihalide.

[0038] The titanium compound may be selected from titanium tetrachloride, titanium tetrabromide, titanium tetraiodide, tetrabutoxytitanium, tetraethoxytitanium, monochlorotriethoxytitanium, dichlorodiethoxytitanium and At least ...

Embodiment 1~5 and comparative example 1

[0071] (1) Preparation of solid catalyst component a

[0072] In the reactor fully replaced by high-purity nitrogen, add 4.8g of magnesium chloride, 95mL of toluene, 4mL of epichlorohydrin, and 12.5mL of tributyl phosphate in sequence, and raise the temperature to 50°C while stirring, and maintain it for 2.5h. The solid is completely dissolved. Add 1.4 g of phthalic anhydride and continue for 1 h. Cool the solution to below -25°C, add 56mL TiCl dropwise within 1h 4 , slowly warming up to 80°C, solids were gradually precipitated during the heating process, 5mmol of the complex internal electron donor compound in Table 1 was added, and the temperature was maintained for 1h. After filtration, they were washed twice with 70mL toluene to obtain solid precipitates. Then add 60mL toluene, 40mL TiCl 4 , the temperature was raised to 110°C and maintained for 2h, the same operation was repeated once, and then washed three times with 70mL toluene at 110°C for 10min each, then 60mL of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com