A kind of preparation method and application of viscosity reducing rheological agent for papermaking coating

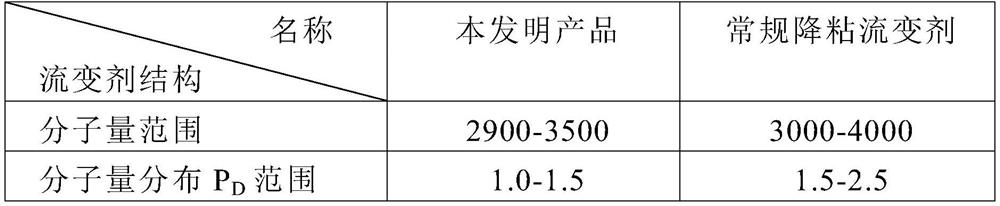

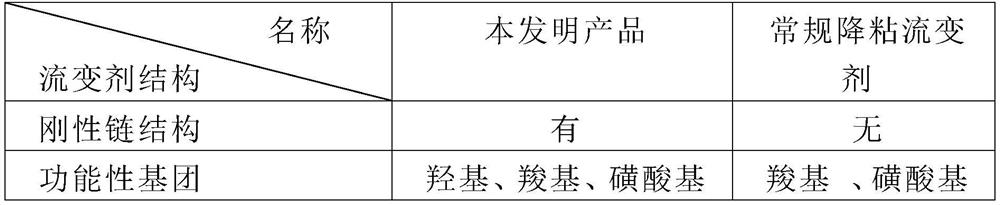

A rheological agent and viscosity reduction technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve problems such as drop, and achieve good viscosity reduction effect and uniform molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

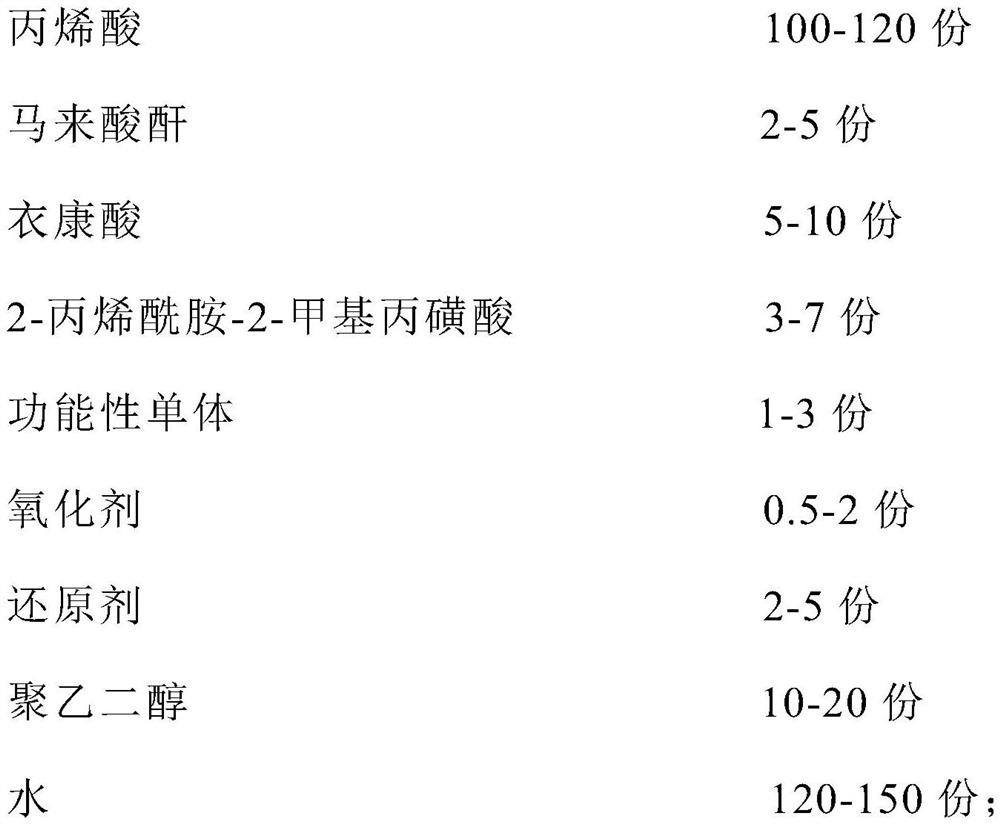

Method used

Image

Examples

Embodiment 1

[0027] Add 130g of water, 5g of maleic anhydride and 10g of itaconic acid into a four-neck flask, raise the temperature to 60-70°C and stir to dissolve, dissolve 6g of 2-acrylamide-2-methylpropanesulfonic acid, 1g of benzyl acrylate, Mix and dissolve 100g of acrylic acid and 20g of water, and wait for use. At the same time, dissolve 2g of ammonium persulfate into 16g of water to prepare an oxidizing agent solution, and dissolve 3g of sodium metabisulfite into 30g of water to prepare a reducing agent solution. When the temperature is between 70-80°C, At the same time, drip the oxidant solution, the reducing agent solution, and drop the mixed functional monomers into the above-mentioned four-necked flask to participate in the reaction, control the temperature at 80-95°C for 60-120 minutes, and then keep the temperature for 20-50 minutes; add 15g poly Ethylene glycol (M W =1000) dissolution reaction, the temperature is reacted at 80-95°C for 30-50min; the temperature is lowered t...

Embodiment 2

[0029] Add 120g of water, 2.5g of maleic anhydride and 5g of itaconic acid into a four-neck flask, raise the temperature to 60-70°C and stir to dissolve, dissolve 5g of 2-acrylamide-2-methylpropanesulfonic acid, 2g of 2-vinylpyridine , 110g of acrylic acid and 20g of water are mixed and dissolved, set aside, at the same time, dissolve 2g of ammonium persulfate in 16g of water to prepare an oxidizing agent solution, dissolve 3g of sodium metabisulfite in 30g of water to prepare a reducing agent solution, and wait until the temperature is between 70-80°C At the same time, drop the oxidant solution, the reducing agent solution, and drop the mixed functional monomers into the above-mentioned four-necked flask to participate in the reaction, control the temperature at 80-95°C for 60-120 minutes, and then keep the temperature for 20-50 minutes; add 10g polyethylene glycol (M W =1500) dissolution reaction, the temperature is reacted at 80-95°C for 30-50min; the temperature is lowered...

Embodiment 3

[0031] Add 130g of water, 4g of maleic anhydride and 8g of itaconic acid into a four-neck flask, raise the temperature to 60-70°C and stir to dissolve, dissolve 6g of 2-acrylamide-2-methylpropanesulfonic acid, 3g of benzylmethyl acrylate, Mix and dissolve 100g of acrylic acid and 20g of water, and wait for use. At the same time, dissolve 2g of ammonium persulfate in 16g of water to prepare an oxidizing agent solution, and dissolve 2.5g of sodium metabisulfite in 30g of water to prepare a reducing agent solution, and wait until the temperature is between 70-80°C At the same time, dropwise add oxidant solution, reducing agent solution, and drop mixed functional monomers to the above-mentioned four-necked flask to participate in the reaction, control the temperature at 80-95°C and add dropwise for 60-120min, then keep warm for 20-50min; add 20g polyethylene glycol (M W =2000) dissolution reaction, the temperature is reacted at 80-95°C for 30-50min; the temperature is lowered to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com