Nanometer porous zinc electrode for electrochemical reduction of carbon dioxide, and preparation and application thereof

A nanoporous, carbon dioxide technology, applied in nanotechnology, electrodes, nanotechnology, etc. for materials and surface science, can solve problems such as limited development prospects, low current density, and small global reserves, and achieve a simple and easy-to-control preparation process , Improve catalytic activity, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

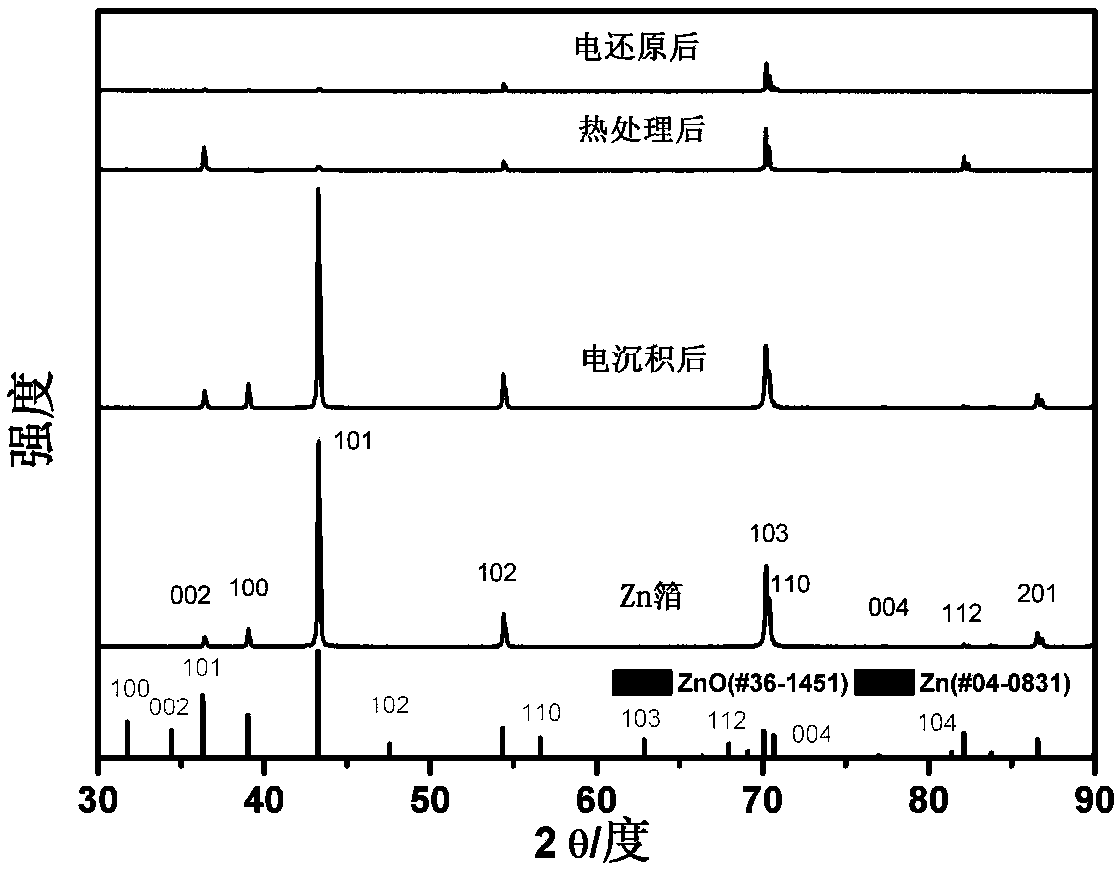

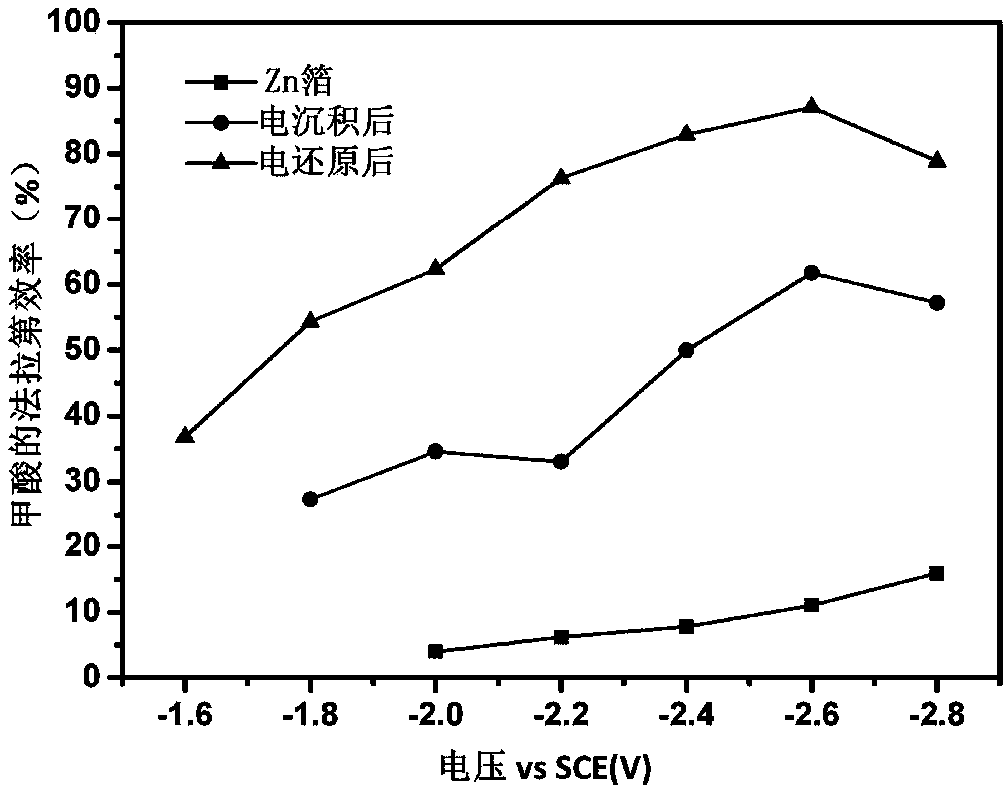

Embodiment 1

[0037] After the 1mm Zn foil was cleaned with ethanol and ultrapure water, it was placed in 85% H 3 PO 4 solution, at 10mA cm -2 The current density was leveled for 300s, and then cleaned with ultrapure water and dried in argon as the substrate; under the protection of argon, 4g ZnO was added to 100ml, 6M KOH aqueous solution as the electroplating solution, at -10mA cm -2 Conduct metal deposition for 300s, then wash with ultrapure water, and dry under the protection of argon; after washing and drying, place in a tube furnace with air at 300°C for 8h; place the heat-treated electrode in CO 2 Saturated with 0.5M NaHCO 3 In the solution, reduce for 15 minutes under the condition of -1.5V to obtain the electrode.

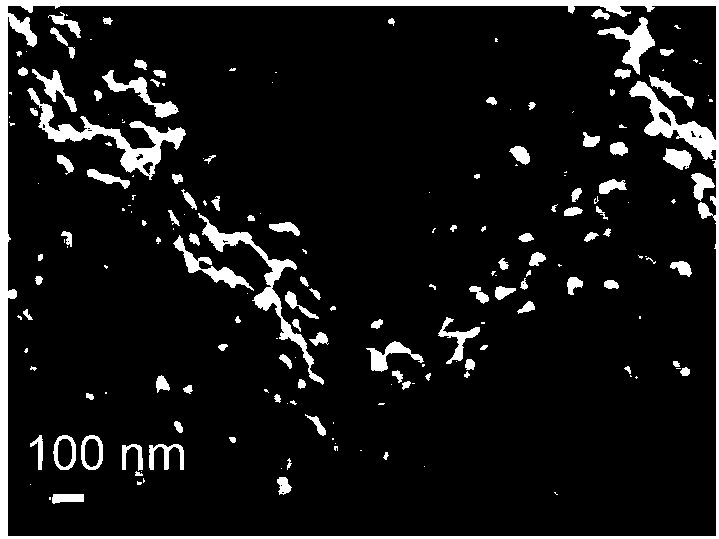

[0038] The Zn electrodeposition layer thickness of the electrode is about 1.5 μm, the thickness of the Zn catalyst nanolayer is about 240nm, the Zn catalyst nanolayer contains pores with a diameter of 50nm-150nm, and the porosity of the Zn catalyst nanolayer is 5%; t...

Embodiment 2

[0043] After the Zn foil was treated with ethanol and ultrapure water, it was placed in 85% H 3 PO 4 solution, at 15mA cm -2 The current density was leveled for 100s, and then cleaned with ultrapure water and dried in argon as the substrate; 5g ZnO was added to 100ml, 10M KOH aqueous solution as the electroplating solution, at -20mA cm -2 Carry out metal deposition for 240s; after washing and drying, place in a tube furnace with air at 300°C for 10h; place the heat-treated electrode in CO 2 Saturated with 0.5M NaHCO 3 In the solution, reduce for 15 minutes under the condition of -1.4V to obtain the electrode.

[0044] The Zn electrodeposition layer thickness of the electrode is about 2 μm, the Zn catalyst nano layer thickness is about 300nm, the Zn catalyst nano layer contains pores with a diameter of 50nm-250nm, and the porosity of the Zn catalyst nano layer is 6%; the surface of the Zn catalyst nano layer is nanometer The particle size of the particles is 100nm-150nm. T...

Embodiment 3

[0046] After the Zn foil was treated with ethanol and ultrapure water, it was placed in 80% H 3 PO 4 solution, at 10mA cm -2 The current density was leveled for 240s, and then cleaned with ultrapure water and dried in argon as the substrate; 5g ZnO was added to 100ml, 7M KOH aqueous solution as the electroplating solution, at -10mA cm -2 Carry out metal deposition for 600s; after washing and drying, place in a tube furnace with air at 330°C for 8h; place the heat-treated electrode in CO 2 saturated with 0.5M KHCO 3 In the solution, reduce for 30 minutes under the condition of -1.5V to obtain the electrode.

[0047] The Zn electrodeposition layer thickness of the electrode is about 3 μm, the Zn catalyst nano layer thickness is about 200nm, the Zn catalyst nano layer contains pores with a diameter of 20nm-100nm, and the porosity of the Zn catalyst nano layer is 2%; the surface of the Zn catalyst nano layer is nanometer The particle size of the particles is 10nm-60nm. This e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com