Hydrocracking catalyst for heavy oil and preparation method of hydrocracking catalyst

A cracking catalyst, heavy oil hydrogenation technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of poor oil solubility, unenvironmental protection, and low metal content and other problems, to achieve the effect of improving hydrogenation reaction activity, inhibiting reaction coke, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of above-mentioned hydrocracking catalyst comprises the following steps:

[0025] (1) Dissolve and disperse the hexavalent molybdenum source compound with the solvent, add an inorganic acid catalyst, the mass ratio of the inorganic acid catalyst to the hexavalent molybdenum source is (0.05~0.2):1, then add C1~C5 organic acid at a temperature of 40~150 Reaction under ℃, described solvent is benzene, toluene or water;

[0026] (2) adding C6-C16 organic acid or C6-C16 ester to the product of step (1), and reacting at a temperature of 160-320°C;

[0027] (3) separating the product obtained in step (2), removing the solvent phase, washing the oil phase with water, and distilling under reduced pressure to obtain a hydrocracking catalyst.

[0028] In the preparation method of the heavy oil hydrocracking catalyst provided by the present invention, preferably, in step (1), the solvent and the hexavalent molybdenum source compound are dissolved and dispers...

Embodiment 1

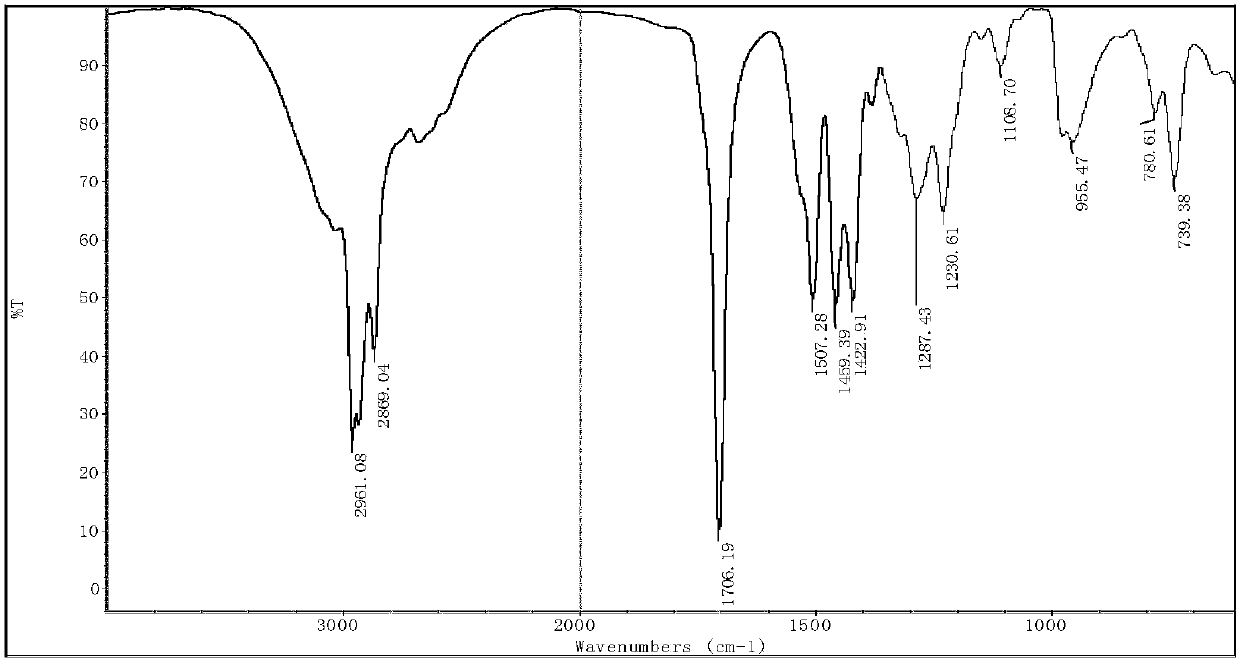

[0038] (NH 4 ) 6 Mo 7 o 24 Dissolve and disperse in a flask with water at a mass ratio equal to 1:20, add 1.5ml of concentrated hydrochloric acid dropwise, purging with an inert gas, add formic acid at a temperature of 70°C for 4 hours, the amount of formic acid is the same as (NH 4 ) 6 Mo 7 o 24 The molar ratio is 3:1; according to (NH 4 ) 6 Mo 7 o 24 Add hexanoic acid at a molar ratio of 1:6 and add hexanoic acid for 20 minutes. After the addition of hexanoic acid, react at a temperature of 170°C for 10 hours; separate the product, remove the solvent phase, wash the oil phase with water, and collect it by distillation under reduced pressure. The product organic molybdenum salt. The infrared spectrogram of gained organic molybdenum salt sees figure 1 ,Depend on figure 1 Visible: Mo atom and carboxyl RCOO - Bonded, 1500cm -1 COO nearby - The asymmetric and symmetric stretching vibrations can confirm that the synthesized compound is an organic molybdenum salt. T...

Embodiment 2

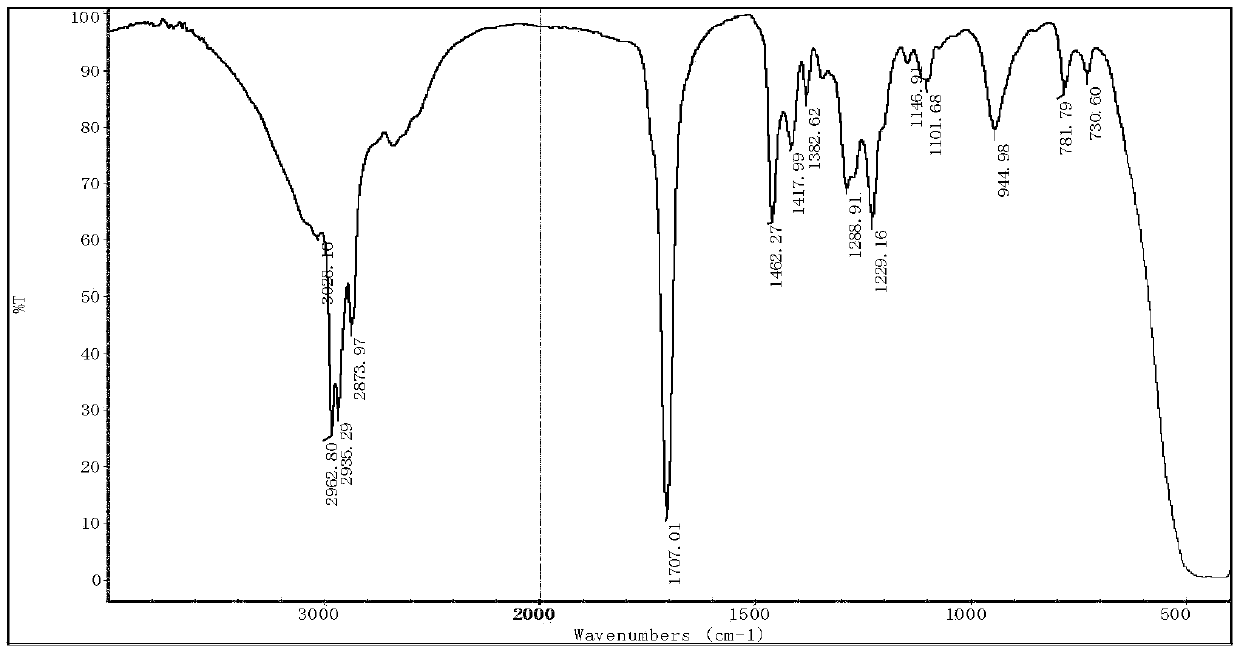

[0040] Molybdenum trioxide and toluene were dissolved and dispersed in the flask according to the mass ratio equal to 1:10, 0.8ml of concentrated sulfuric acid was added dropwise, purged with inert gas, and acetic acid was added to react at a temperature of 105°C for 4 hours, the amount of acetic acid was the same as the amount of molybdenum trioxide The ratio is 2; add heptanoic acid according to the mass ratio of molybdenum trioxide and heptanoic acid is 1:8, the addition time is 5min, after the addition of heptanoic acid is completed, react at a temperature of 220°C for 4 hours; separate the product and remove the solvent phase, the oil phase was washed with water, and the product was collected by distillation under reduced pressure. The infrared spectrum of the resulting product is shown in figure 2 ,Depend on figure 2 Visible: Mo atom and carboxyl RCOO - Bonded, 1500cm -1 COO nearby - The asymmetric and symmetric stretching vibrations can confirm that the synthesize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com