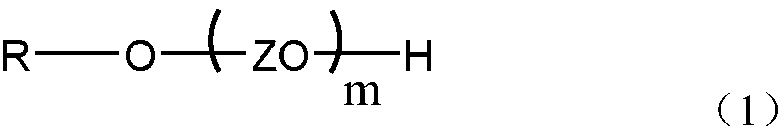

Alkali-free accelerator with shrinkage function and preparation method thereof

An accelerator and functional technology, applied in the field of liquid alkali-free accelerator and its preparation, can solve the problems of low crack resistance and excessive shrinkage of shotcrete, and achieve improved crack resistance, rapid hardening and shrinkage reduction, The effect of reducing the rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

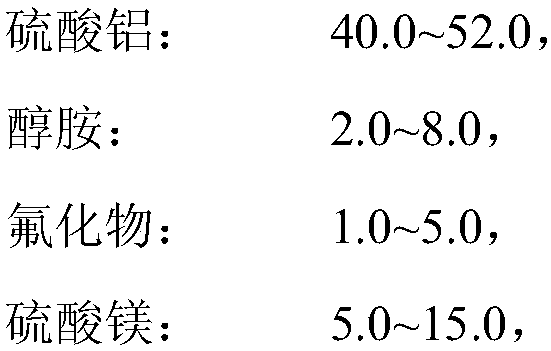

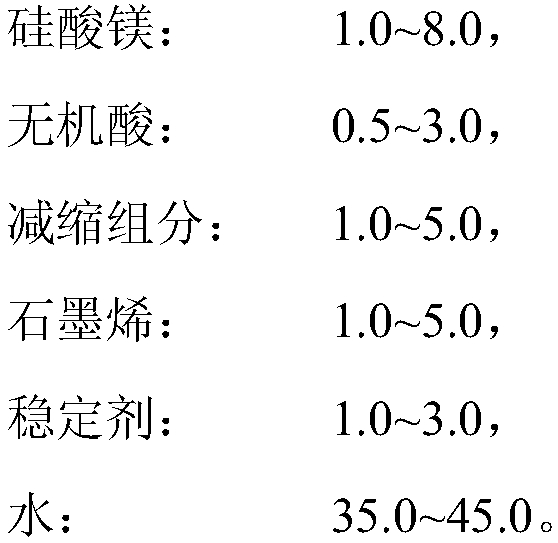

[0043] The preparation of the liquid alkali-free quick-setting agent with shrinkage and anti-cracking function comprises the following steps:

[0044] (1) Mix 40g of aluminum sulfate, 2g of diethanolamine, 2g of aluminum fluoride, 5g of magnesium sulfate, 1g of phosphoric acid and 42g of water, heat up to 80-90°C, stir, and react for 2-4 hours;

[0045] (2) After the reactant in step (1) is completely dissolved, cool down to below 60°C, add 3g of shrinkage reducing component and 1g of sulfonated graphene, and stir for 1-2h;

[0046] (3) After completely dissolving the reactant in step (2), heat up to 90-95°C, add 2g of magnesium silicate, and stir for 1h;

[0047] (4) Rapidly cool the product of step (3) to below 50°C within 0.5h, add 2g of polyvinyl alcohol, stir for 1-2h, and completely dissolve to obtain the liquid alkali-free accelerator with shrinkage-reducing and anti-cracking functions .

Embodiment 2

[0049] The preparation of the liquid alkali-free quick-setting agent with shrinkage and anti-cracking function comprises the following steps:

[0050] (1) Mix 43g of aluminum sulfate, 3g of diethanolamine, 2g of sodium fluoride, 5g of magnesium sulfate, 1g of phosphoric acid and 42g of water, heat up to 80-90°C, stir, and react for 2-4 hours;

[0051] (2) After the reactant in step (1) is completely dissolved, cool down to below 60°C, add 2g shrinkage reducing component and 2g sulfonated graphene, and stir for 1-2h;

[0052] (3) After completely dissolving the reactant in step (2), heat up to 90-95°C, add 2g of magnesium silicate, and stir for 1h;

[0053] (4) Rapidly cool the product of step (3) to below 50°C within 0.5h, add 2g of polyvinyl alcohol, stir for 1-2h, and completely dissolve to obtain the liquid alkali-free accelerator with shrinkage-reducing and anti-cracking functions .

Embodiment 3

[0055] The preparation of the liquid alkali-free quick-setting agent with shrinkage and anti-cracking function comprises the following steps:

[0056] (1) Mix 45g of aluminum sulfate, 2g of triethanolamine, 2g of sodium fluoride, 5g of magnesium sulfate, 1g of oxalic acid and 38g of water, heat up to 80-90°C, stir, and react for 2-4 hours;

[0057] (2) After the reactant in step (1) is completely dissolved, cool down to below 60°C, add 2g of shrinkage reducing component and 1g of sulfonated graphene, and stir for 1-2h;

[0058] (3) After completely dissolving the reactant in step (2), heat up to 90-95°C, add 3g of magnesium silicate, and stir for 1h;

[0059] (4) Rapidly cool the product of step (3) to below 50°C within 0.5h, add 1g of cellulose ether, stir for 1-2h, and completely dissolve to obtain the liquid alkali-free accelerator with shrinkage-reducing and anti-cracking functions .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com