Preparation of oxalate decarboxylase as well as product and application of oxalate decarboxylase

An oxalate decarboxylase, acid-induced technology, applied in the directions of application, medical preparations containing active ingredients, biochemical equipment and methods, etc., can solve the problems of unindustrialization, low normal expression of oxalate decarboxylase, etc., and reduce food consumption. The effect of oxalic acid absorption and prevention of calcium oxalate urinary tract stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

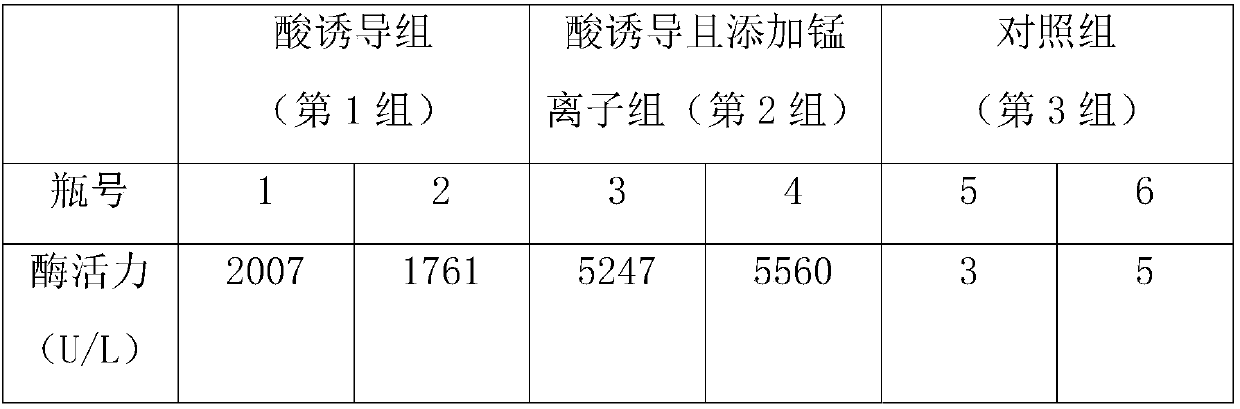

[0035] Example 1: Effects of different induction methods on the production of oxalate decarboxylase

[0036] This embodiment illustrates the impact of different induction methods on the enzyme production of the oxalate decarboxylase of the fungus of the genus Amanita genus, and the specific operations are as follows:

[0037] Tea Tree Mushroom was used as the strain to culture and produce oxalate decarboxylase in shake flasks. The medium formula was: yeast powder, 4g / L; soybean peptone, 3g / L; KH 2 PO 4 , 2g / L; MgSO 4 ·7H 2 O, 0.2g / L; CaCl 2 , 1g / L; Glucose, 20g / L; Corn starch, 10g / L; Vitamin B 1 10mg / L; pH value 5.0-6.0; shake bottle liquid volume is 20-30%, sterilized at 121°C for 30 minutes (vitamin B 1 For filter sterilization, add to culture medium before inoculation). Inoculate the mycelium of tea tree mushroom cultured on the PDA plate into 3 groups (6 shake flasks) of sterilized liquid culture medium respectively, the inoculum amount remains the same, and the cult...

Embodiment 2

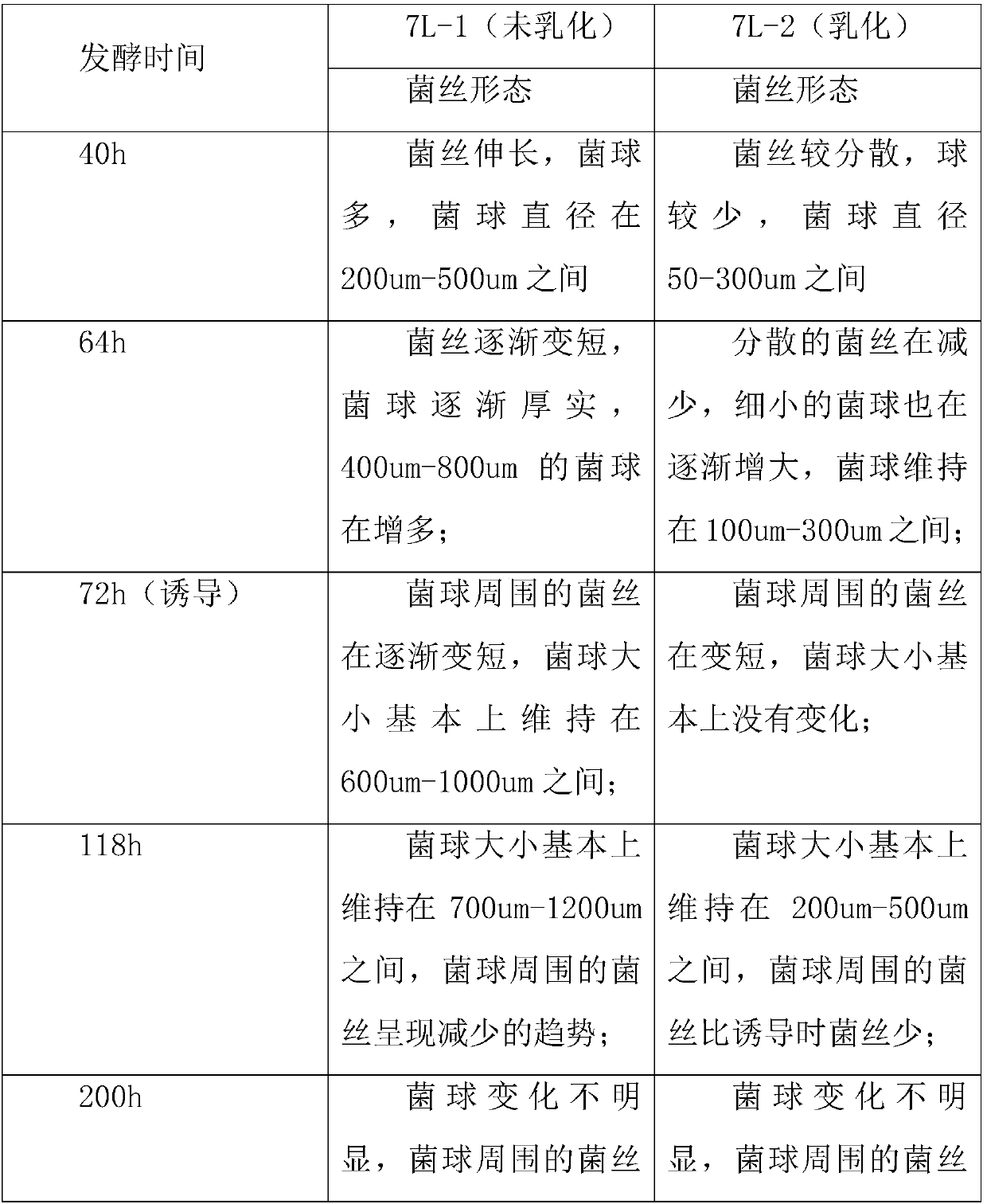

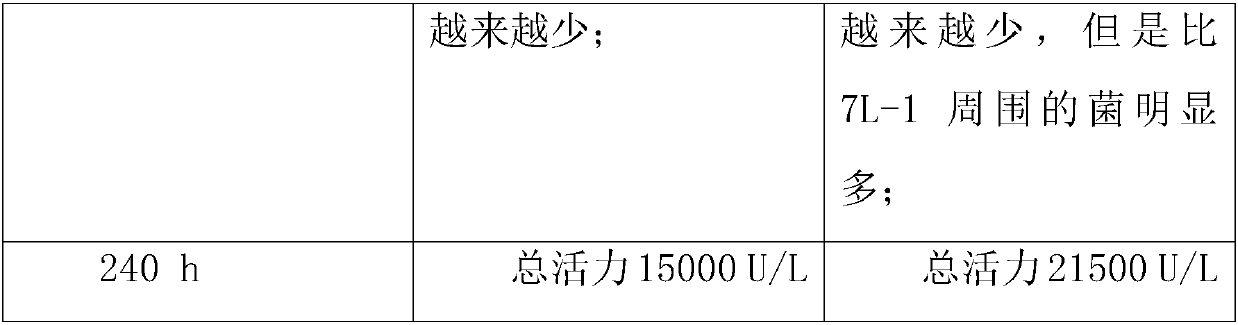

[0040] Example 2: Effect of Bacillus Control on Enzyme Activity

[0041] This example provides the effect of the control of mycospheres on the production of oxalate decarboxylase enzyme activity during the fermentation process by comparing the fermentation of two 7L fermenters. Specific steps are as follows:

[0042] 1) Take tea tree mushroom as the strain, use shake flask to cultivate the seed solution, and divide it into two parts. Seed medium: yeast powder, 4g / L; soybean peptone, 6g / L; KH 2 PO 4 , 1g / L; MgSO 4 ·7H 2 O, 0.5g / L; CaCl 2 , 0.1g / L; Glucose, 20g / L; Corn starch, 10g / L; Vitamin B 1 10mg / L; pH value 5.0-6.0; shake flask filling volume 20-30%, culture conditions: 23-28°C, 100rpm-350rpm for 3 days as seed solution. When a seed liquid is subcultured and amplified, use a hand-held emulsifier to crush the fungus balls; when the other seed liquid is amplified, transfer directly without crushing the emulsifier. The seed liquid is transferred to the fermentation med...

Embodiment 3

[0049] This embodiment provides a method for preparing enzyme powder and edible fungus powder containing oxalate decarboxylase, and the specific steps are as follows:

[0050] 1) Use tea tree mushroom as strain, adopt shake flask to cultivate seed solution, seed medium is: yeast powder, 4g / L; soybean peptone, 3g / L; KH 2 PO 4 , 2g / L; MgSO 4 ·7H 2 O, 0.2g / L; CaCl 2 , 1g / L; Glucose, 20g / L; Corn starch, 10g / L; Vitamin B 1 10mg / L; pH value 5.0~6.0; shake flask filling volume is 20~30%, culture conditions: 23~28℃, 100rpm~350rpm for 2~5 days, when the seed liquid is subcultured and enlarged, the method of mechanical crushing is adopted Break the bacterium ball and transfer it to the next-level seed medium with an inoculation amount of 10% to 30%;

[0051] 2) The mycelial balls of the seed liquid are mechanically crushed and inoculated into a 7L mechanically stirred fermenter with an inoculum size of 10% to 30% for fermentation. The liquid fermentation medium includes the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com