Preparation of paraffin/silicone rubber microencapsulated phase change materials

A technology of phase change microcapsules and silicone rubber, which is applied in the field of thermal insulation materials, and achieves the effects of convenient use, wide application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

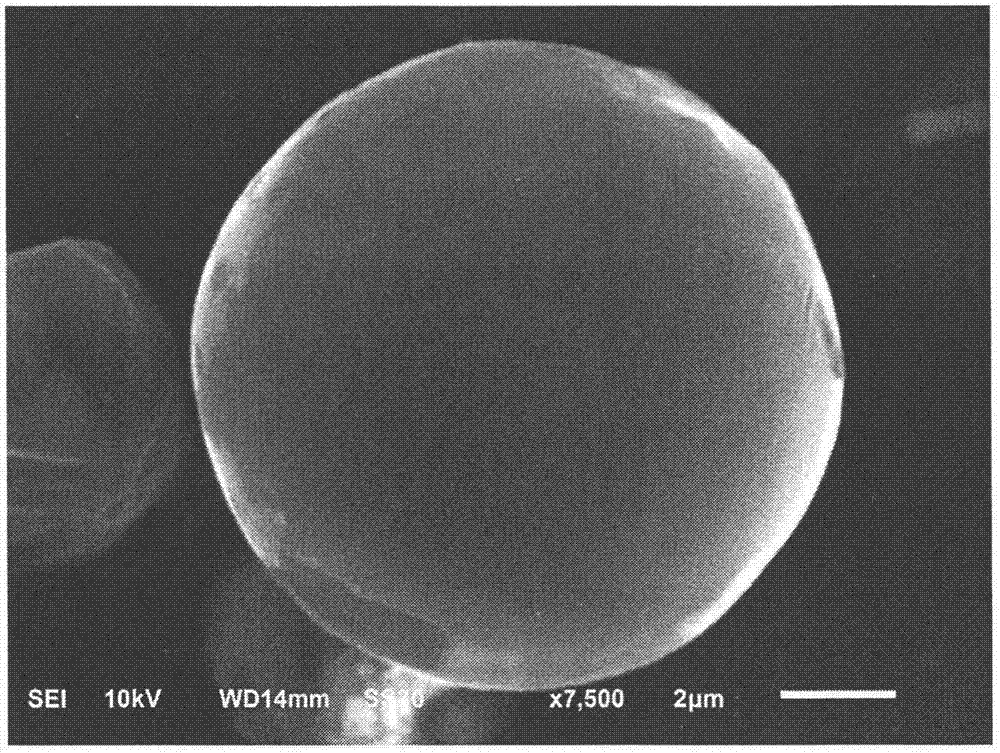

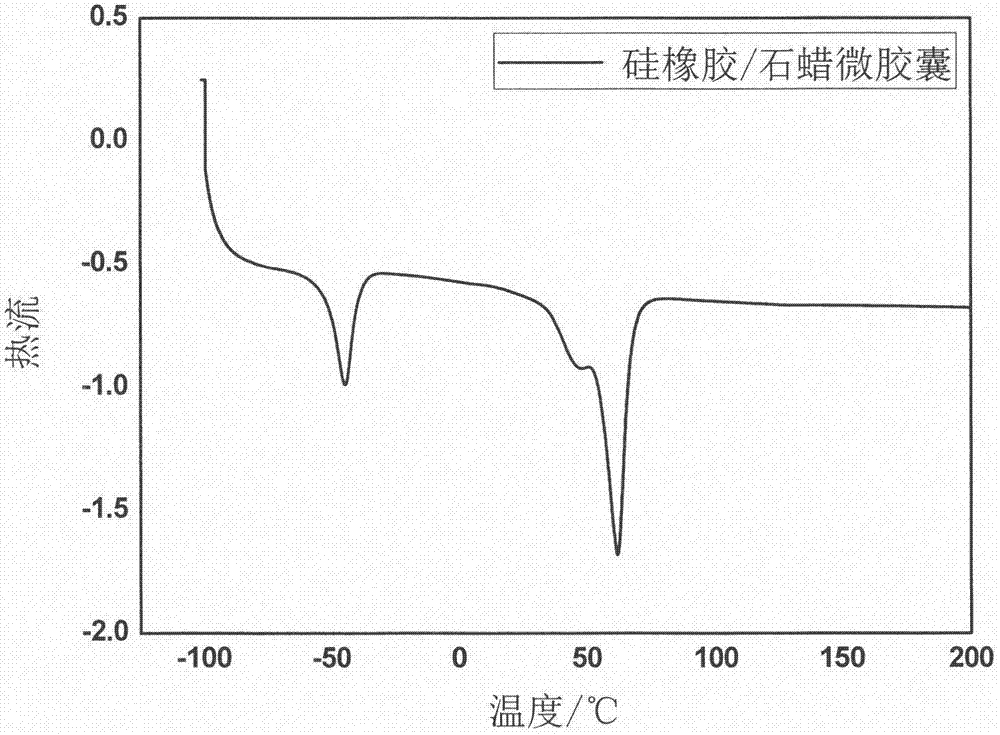

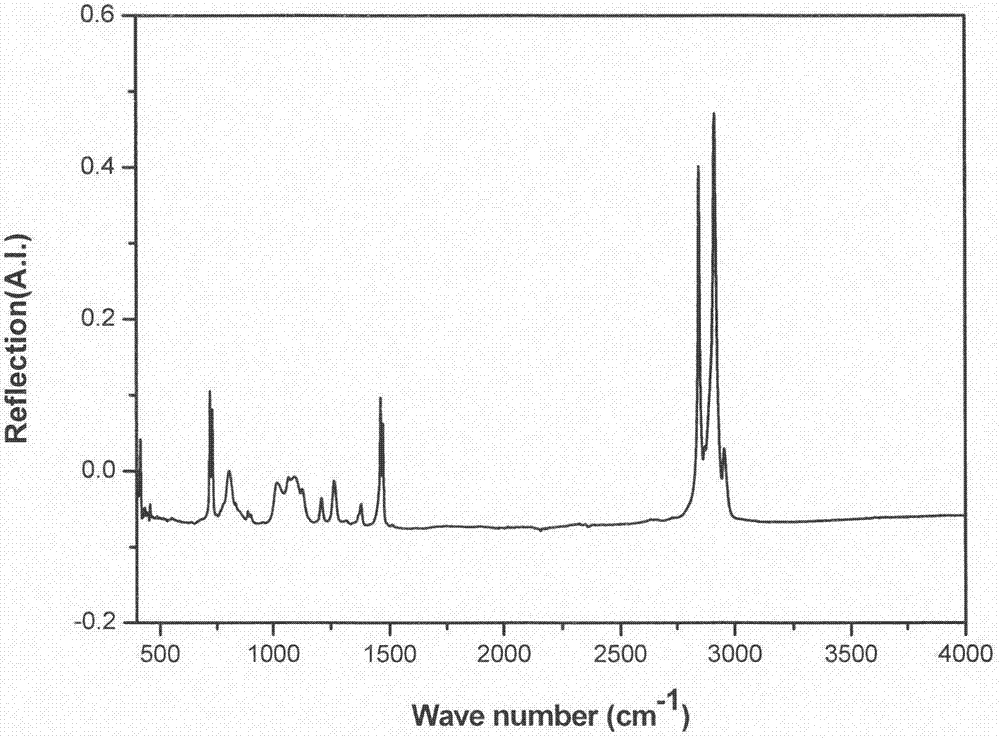

[0026] Such as Figure 1~3 As shown, the paraffin silicone rubber phase-change microcapsule composite material is characterized in that it includes: a silicone rubber / paraffin microsphere composite composed of silicone rubber and paraffin microspheres.

[0027] The material of the silicone rubber includes H1100 room temperature vulcanized fluorosilicone rubber (Shenzhen Guanheng Co., Ltd.).

[0028] The paraffin microspheres are micron-sized paraffin microspheres.

[0029] The preparation method of paraffin silicone rubber phase change microcapsule composite material is characterized in that: comprising the following steps:

[0030] S01, weigh the paraffin microspheres according to the mass ratio and put them in a beaker, add an appropriate amount of aqueous solution, and add a surfactant to it and stir for 5 minutes; the mass ratio is paraffin:surfactant=10:2.

[0031] S02, take the silicone rubber according to the mass ratio, add curing agent (curing agent: silicone rubber...

Embodiment 2

[0038] Such as Figure 1~3 As shown, the paraffin silicone rubber phase change microcapsule composite material is characterized in that it includes: a silicone rubber / paraffin microsphere composite made of silicone rubber and paraffin microspheres.

[0039] The material of the silicone rubber includes H1100 room temperature vulcanized fluorosilicone rubber (Shenzhen Guanheng Co., Ltd.).

[0040] The paraffin microspheres are micron-sized paraffin microspheres.

[0041] The preparation method of paraffin silicone rubber phase change microcapsule composite material is characterized in that: comprising the following steps:

[0042] S01, weigh the paraffin microspheres according to the mass ratio and put them in a beaker, add an appropriate amount of aqueous solution, and add a surfactant to it and stir for 5 minutes; the mass ratio is paraffin:surfactant=10:3.

[0043] S02, take the silicone rubber according to the mass ratio, add curing agent (curing agent: silicone rubber=1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com