Preparation method of cerium-doped rare earth silicate polycrystalline powder

A rare earth silicate, polycrystalline powder technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complex operation process, affecting the performance of lutetium silicate crystal material such as light output, long reaction period, etc. Simple process flow, low cost and uniform distribution of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the cerium-doped rare earth silicate polycrystalline powder provided by the present invention specifically comprises the following steps:

[0025] The chemical formula of the cerium-doped rare earth silicate polycrystalline powder is RE 2(1-x) SiO 5 : Ce 2x , where x=0.5‰-2%, RE is one or two of Y, Gd, Lu;

[0026] Step 1. Weigh one or both of cerium nitrate, yttrium nitrate, gadolinium nitrate and lutetium nitrate according to the molar ratio of the rare earth element in the above chemical formula, and mix and stir the weighed rare earth nitrate solution to obtain the first solution;

[0027] Step 2, weighing sodium metasilicate according to the molar ratio of rare earth element and silicon element in the above chemical formula, and mixing and stirring the weighed sodium metasilicate with ammonia water or ammonium carbonate solution to obtain a second solution;

[0028] Step 3. Under the condition of magnetic stirring, slowly add the first...

Embodiment 1

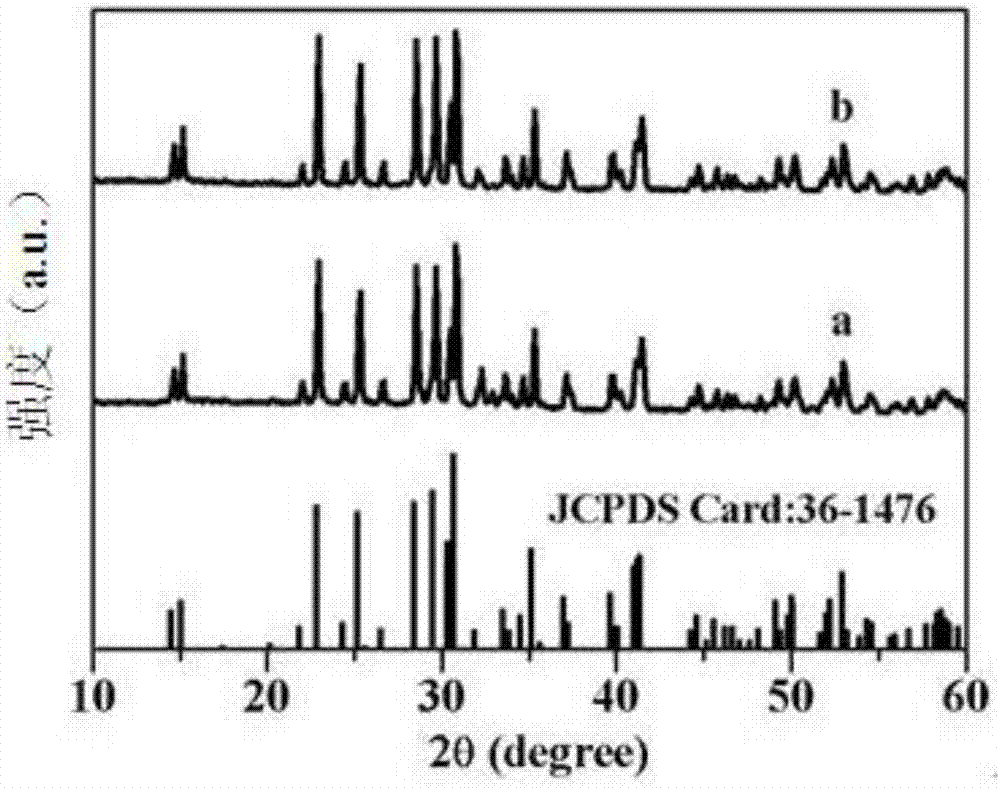

[0030] Example 1: Y 2 SiO 5 :1‰Ce polycrystalline powder preparation

[0031] According to the proportion of cerium in the total rare earth is 1‰, the total rare earth is 0.012mol yttrium nitrate solution and cerium nitrate solution are mixed uniformly; 0.006mol sodium metasilicate solution and 0.024mol ammonia solution are stirred uniformly; under magnetic stirring conditions, the The above mixed rare earth solution was slowly added dropwise to the mixed solution of sodium metasilicate and ammonia water, stirred for 2 hours, and aged overnight to obtain mixed precipitates of rare earth-containing colloidal silica and rare earth hydroxides, which were separated with deionized water and absolute ethanol Washing; first dry the mixed precipitate at 70°C for 24h, then in N 2 / H 2 Calcined at 1300°C for 2h in a mixed atmosphere (volume ratio 9:1) to obtain Y 2 SiO 5 :1‰Ce polycrystalline powder.

Embodiment 2

[0032] Example 2: Y 2 SiO 5 : Preparation of 1% Ce polycrystalline powder

[0033] According to cerium accounting for 1% of the total rare earth ratio, the total rare earth is 0.012mol yttrium nitrate solution and cerium nitrate solution are mixed uniformly; 0.006mol sodium metasilicate solution and 0.024mol ammonia solution are stirred uniformly; under magnetic stirring conditions, the The above mixed rare earth solution was slowly added dropwise to the mixed solution of sodium metasilicate and ammonia water, stirred for 2 hours, and aged overnight to obtain mixed precipitates of rare earth-containing colloidal silica and rare earth hydroxides, which were separated with deionized water and absolute ethanol Washing; first dry the mixed precipitate at 70°C for 24h, then in N2 / H 2 Calcined at 1300°C for 2h in a mixed atmosphere (volume ratio 9:1) to obtain Y 2 SiO 5 : 1% Ce polycrystalline powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com