A Large Aperture Liquid Crystal Optical Phased Array Device

A liquid crystal optics, phased array technology, applied in optics, nonlinear optics, instruments, etc., to achieve the effects of light weight, improved resolution, and increased diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

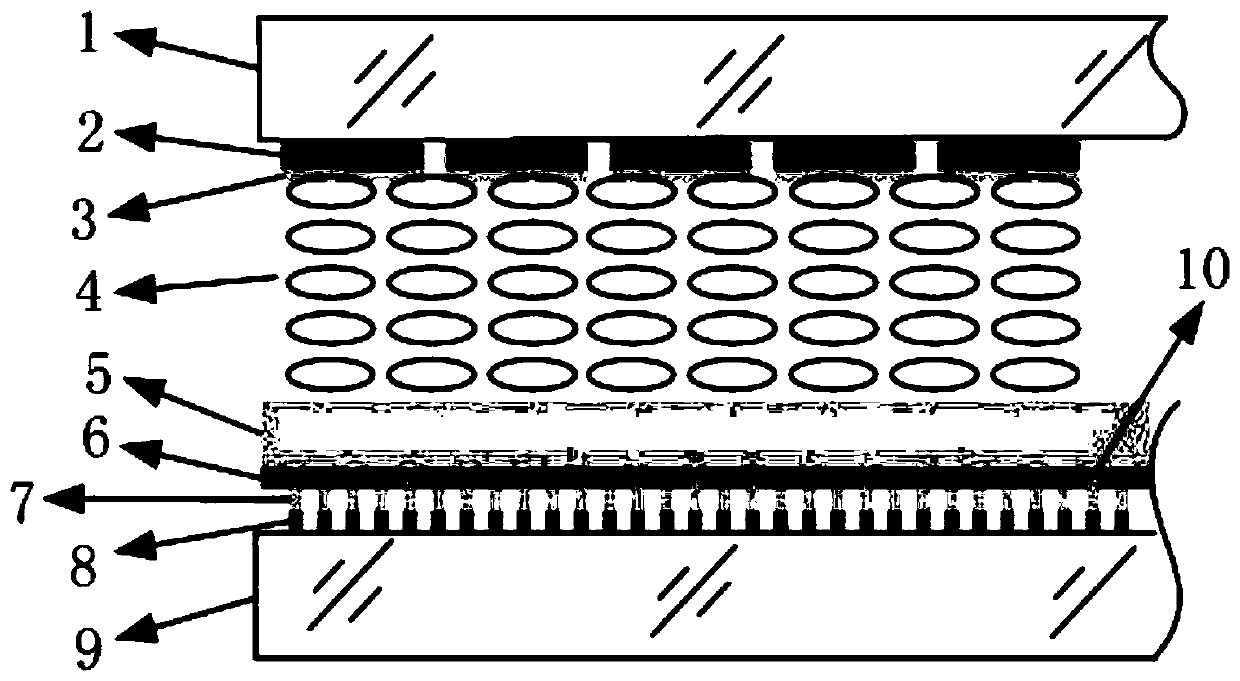

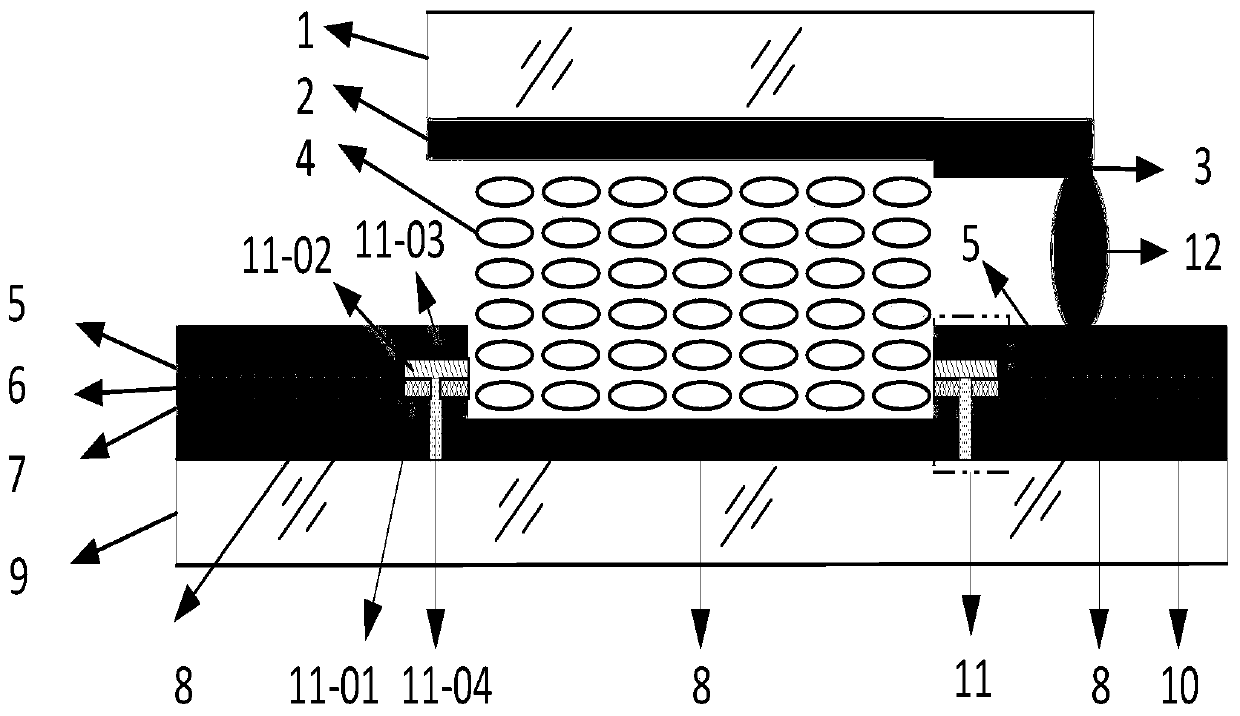

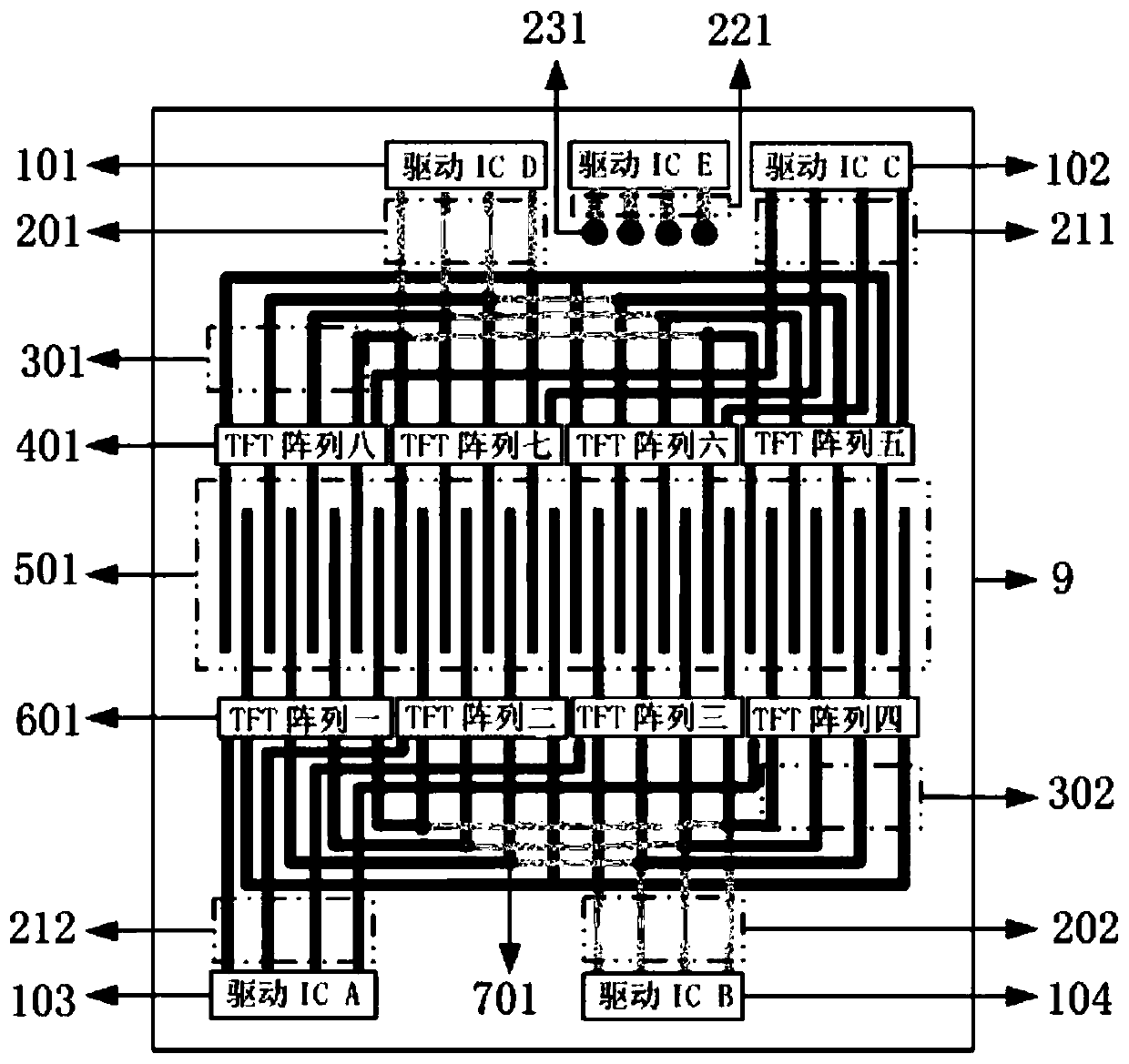

[0019] The invention provides a large-diameter liquid crystal optical phased array device, which mainly includes the via hole design of the film layer, the layout design of the liquid crystal peripheral wires, the design of the liquid crystal drive electrode, the design of the film layer of the upper substrate, the design of the film layer and size of the lower substrate, and the TFT array. and drive scheme design. The technical design of the film layer via means that an insulating layer is sandwiched between the two metal conductive layers of the upper substrate, and the metal wires of one layer and the metal wires of the other layer are electrically connected through the conductive holes. The size of the conductive hole is generally about 0.1um.

[0020] In the layout design of the peripheral wires described above, after a certain area is defined for the liquid crystal electrodes, there is no cross connection between the electrodes between two areas by wiring through via hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com