Processing method for acidized fracturing flow-back fluid

A technology of acid fracturing and treatment methods, which is applied in the fields of chemical instruments and methods, special compound water treatment, water/sewage treatment, etc., which can solve the problems of large consumption of chemicals, poor treatment effect, and increased treatment costs, and achieve improvement Oxidation efficiency, improvement of electrochemical oxidation efficiency, and effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

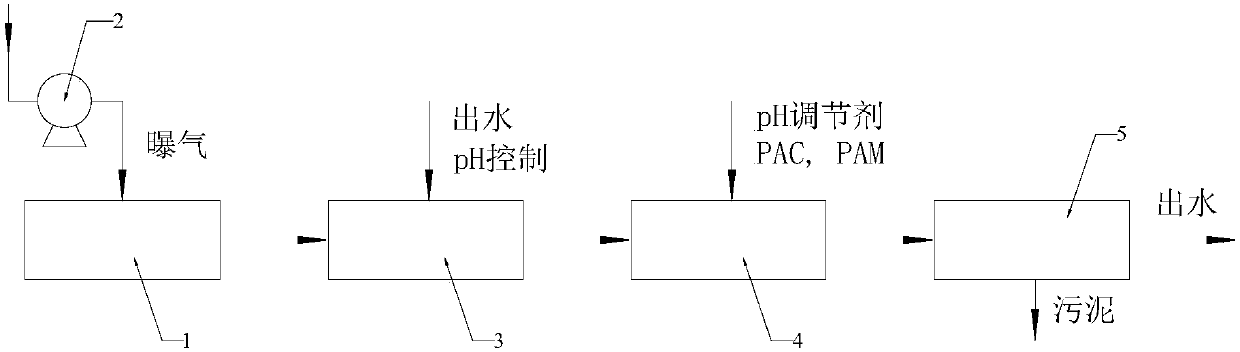

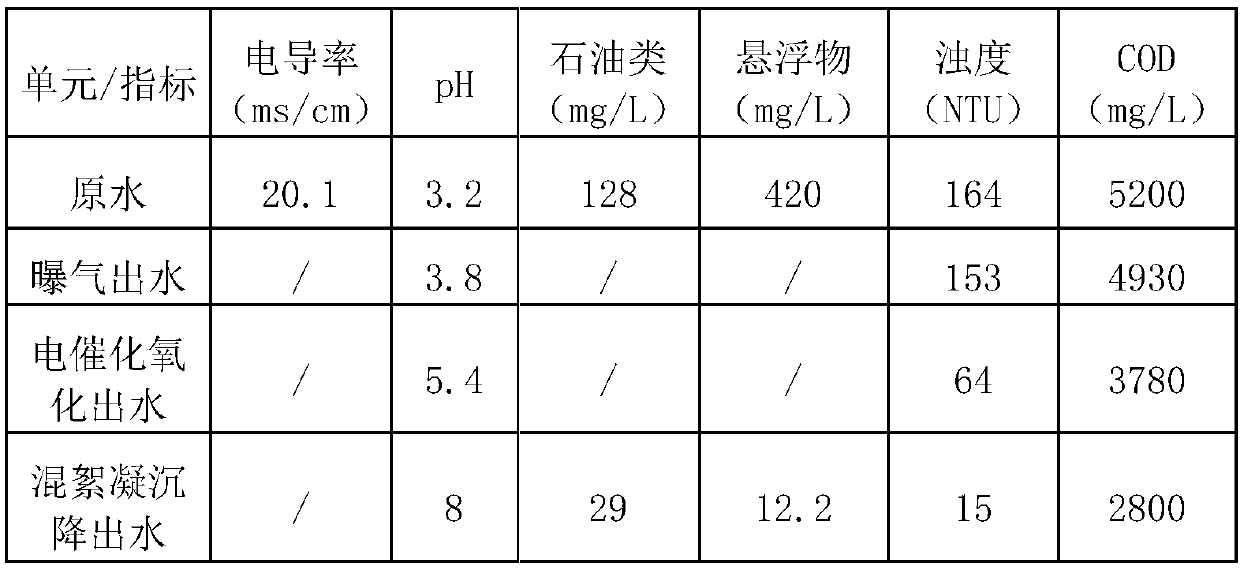

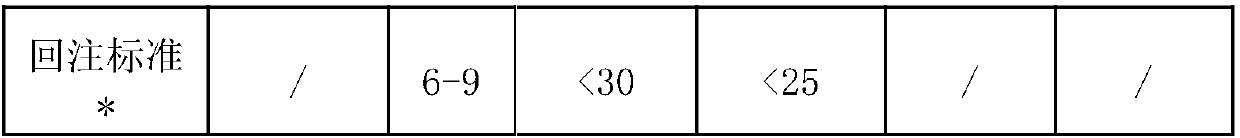

[0044] according to figure 1 As shown, take the following steps:

[0045] (1) Pump the acidified fracturing flowback fluid into the aeration tank through the lift pump, and blow air into the tank, the aeration rate is 250L / min, and the aeration intensity is 3.5m 3 / m 2 h, the residence time is 30min.

[0046] (2) The effluent enters the electrocatalytic oxidation reactor through the pump, and the pH value of the sewage in the reactor is controlled to be 4.0-6.0 through the online monitoring and pH adjustment system during the reaction process. By controlling the automatic control system to adjust the constant current 1000A, the output voltage is 3.8V, so that the current density reaches 8mA / cm 2 , aeration is carried out at the same time, the aeration rate is 100L / min, and the aeration intensity is 1m 3 / m 2 h, residence time 25min.

[0047] (3) Monitor the pH value of the effluent from the electrocatalytic oxidation reactor, add an appropriate amount of pH regulator to ...

Embodiment 2

[0056] Process such as figure 1 As shown, the flocculation process was not adjusted by pH.

[0057] This method is used to treat the acidified fracturing flowback fluid of a fracturing operation in northern Shaanxi. The treated acidified fracturing flowback fluid has pH=5.8, conductivity=10.5ms / cm, COD=1350mg / L, hardness=2200mg / L, turbidity=380NTU. Specifically, it includes the following steps: First, pump the acidified fracturing flowback fluid into the aeration tank with a lift pump, the aeration rate is 200L / min, and the aeration intensity is 3m 3 / m 2 h, the residence time is 20min. Then use the lift pump to input it to the electrocatalytic oxidation reactor, set the pulse power supply constant current reaction, and the current density is 10mA / cm 2 , aeration intensity 1m 3 / m 2 h, residence time 35min. After the reaction, the pH of the effluent reaches 6.8, the concentration of PAC with a mass content of 28% is directly added at a concentration of 150 mg / L, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com