A pramoxine hydrochloride preparing method

A technology of pramoxine hydrochloride and pramoxine, which is applied in the field of pharmaceutical synthesis, can solve the problems of hydroquinone instability, no use found, and high environmental pressure, and achieve low cost, little pollution, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

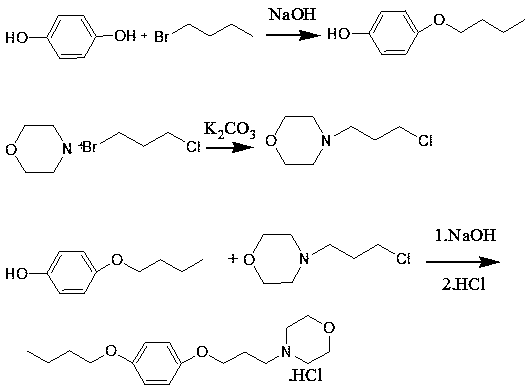

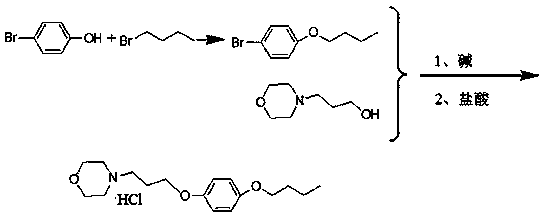

Method used

Image

Examples

example 1

[0035] The preparation of intermediate p-bromobutyrate:

[0036] Add 17.47g (0.101mol) of p-bromophenol into a 250ml reaction flask, add 70g of water and 4.4g (0.11mol) of sodium hydroxide, stir to dissolve, add dropwise 13.7g (0.10mol) of 1-bromobutane, after the addition Heat up, reflux for 6 hours, cool down to 25°C, add 200ml of ethyl acetate, stop stirring after 10 minutes and let stand for liquid separation, wash twice with 100ml of 0.5% sodium hydroxide solution, dry with 20g of anhydrous sodium sulfate for more than 5 hours, 45 ℃ and concentrated to dryness under reduced pressure to obtain 23.2 g of a pale pink liquid with a yield of over 100 and a liquid phase purity of 98.5%.

[0037] Preparation of pramoxine hydrochloride:

[0038] Add 23.2g (0.1mol) of the above-mentioned intermediate, 17.42g (0.12mol) of 3-morpholine-1-propanol and 115g tetrahydrofuran into a 500ml reaction bottle, start stirring, slowly add 4.8g (0.12mol) of 60% sodium hydride, and control Temp...

example 2

[0040] The preparation of intermediate bromobutyrate:

[0041] Add 34.94g (0.202mol) of p-bromophenol into a 500ml reaction flask, add 140g of water and 8.8g (0.22mol) of sodium hydroxide, stir to dissolve, add dropwise 27.40g (0.20mol) of 1-bromobutane, after the addition Heat up, reflux for 6 hours, cool down to 25°C, add 200ml of ethyl acetate, stop stirring after 10 minutes, let stand for liquid separation, wash twice with 200ml of 0.5% sodium hydroxide solution, dry with 40g of anhydrous sodium sulfate for more than 5 hours, 45 ℃ and concentrated to dryness under reduced pressure to obtain 46.0 g of a pale pink liquid with a yield of over 100 and a liquid phase purity of 98.8%.

[0042] Preparation of pramoxine hydrochloride:

[0043] Add 46.0g (0.2mol) of the above-mentioned intermediate, 34.84g (0.24mol) of 3-morpholine-1-propanol and 230g tetrahydrofuran into a 1000ml reaction bottle, start stirring, slowly add 9.6g (0.24mol) of 60% sodium hydride, and control Temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com