A kind of low-odor sterilization micro-foaming scratch-resistant nylon composite material and preparation method thereof

A nylon composite material and micro-foaming technology, which is applied in the field of nylon material modification, can solve the problems of not eliminating the effect of low VOC harmful gases, affecting the mechanical properties of the material, and having limited sterilization effect, so as to achieve photocatalytic performance improvement, spectral The effect of improving the response range and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

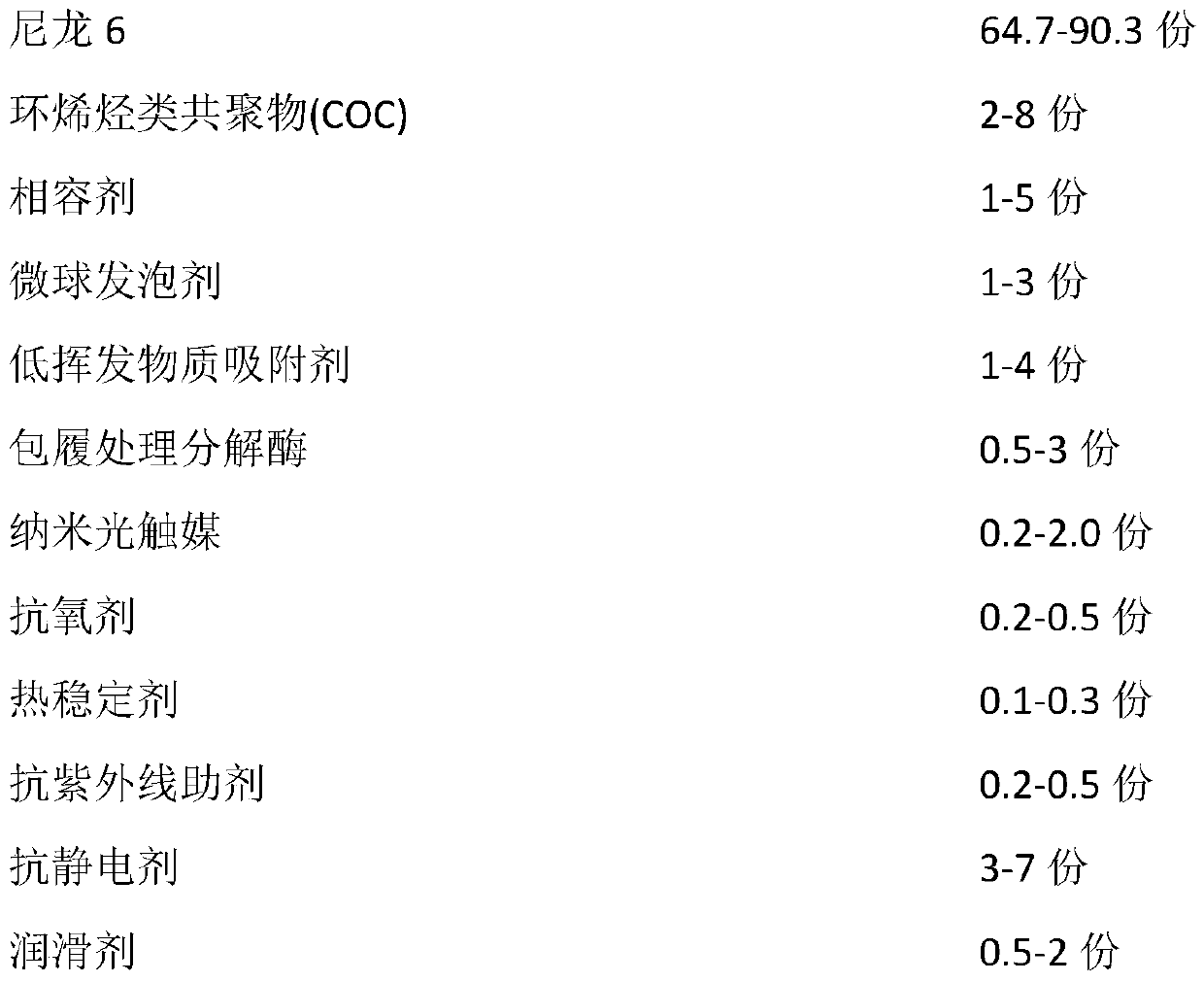

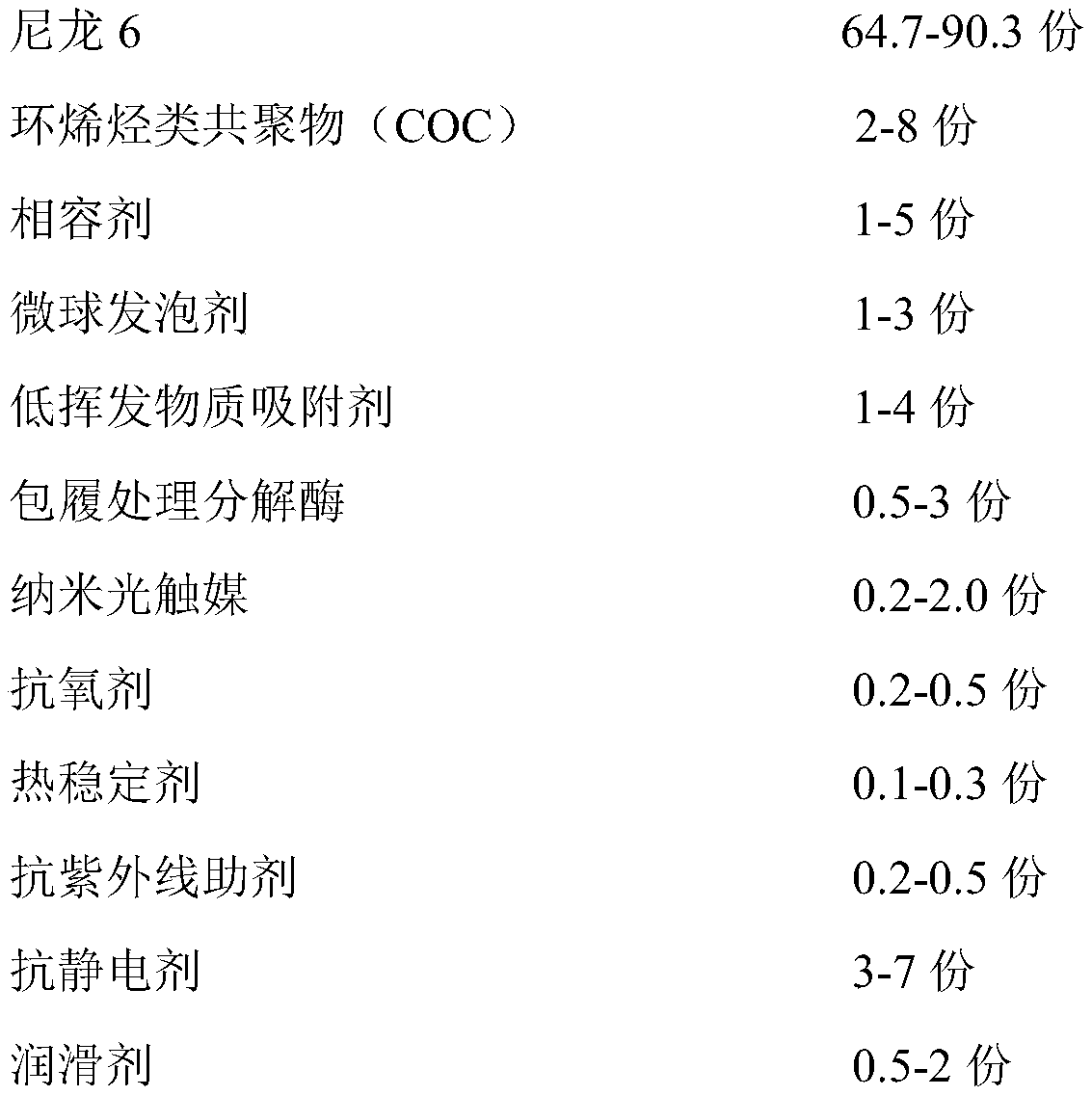

Method used

Image

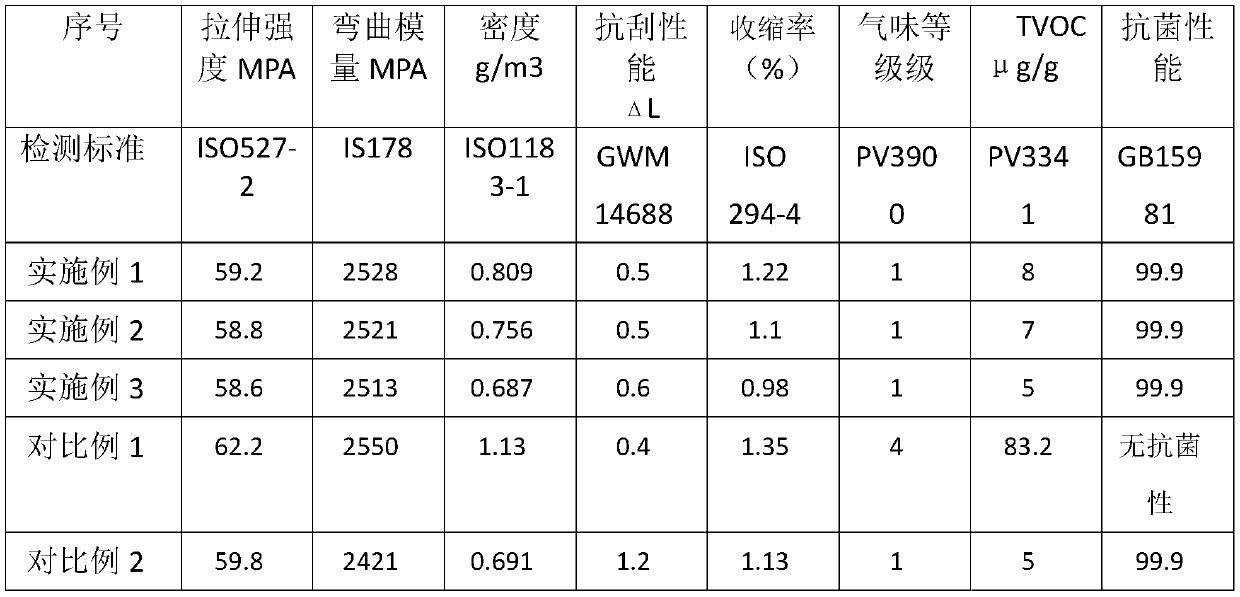

Examples

Embodiment 1

[0042] (1) In parts by weight, the nylon 6 mixture (the ratio of medium-viscosity nylon 6 and high-viscosity nylon 6 is 2:1, the viscosity value of medium-viscosity nylon 6 is 2.8, and the viscosity value of high-viscosity nylon 6 is 3.4) , antistatic agent (Sanyo Chemical’s Pelestat 6500), low-volatile matter adsorbent (nano-silica, acicular zeolite molecular sieve, and sepiolite in a mass ratio of 1:2:1), encapsulation treatment decomposition enzyme ( Japan ECO Co., Ltd. model ECO-E decomposing enzyme), nanometer photocatalyst (Co., Ltd. Longinus model KV-1N photocatalyst) were dried separately for use.

[0043] (2) In parts by weight, 79.23 parts of dried nylon 6 mixture, 5 parts of cycloolefin copolymer (COC), 3 parts of compatibilizer PP-MAH, 1.5 parts of low-volatile matter adsorbent, antioxidant 0.4 part of antioxidant (antioxidant 1098, antioxidant 168 and antioxidant H10 mixed in a mass ratio of 0.2:0.1:0.1), 0.2 part of SAG-005 heat stabilizer, 0.3 part of UV234 anti...

Embodiment 2

[0048] (1) In terms of parts by weight, the nylon 6 mixture (the ratio of medium viscosity nylon 6 and high viscosity nylon 6 is 1:1, the viscosity value of medium viscosity nylon 6 is 2.6, and the viscosity value of high viscosity nylon 6 is 3.3 ), antistatic agent (Sanyo Chemical’s Pelestat 6500), low-volatile matter adsorbent (nano-silica, acicular zeolite molecular sieve, and sepiolite in mass ratio (0.5:3:1.5 composition), packaged and decomposed Enzymes (the decomposing enzyme of Japan ECO Co., Ltd. model ECO-E) and nano photocatalysts (KV-1N photocatalysts of Longinus Co., Ltd.) were dried separately for use.

[0049] (2) In parts by weight, 78.05 parts of dried nylon 6 mixture, 5 parts of cycloolefin copolymer (COC), 3 parts of compatibilizer, 1.8 parts of low volatile matter adsorbent, antioxidant (antioxidant Oxygen 1098, Antioxidant 168 and Antioxidant H10 are mixed according to the mass ratio of 1:1.5:0.5) 0.4 parts, SAG-008 heat stabilizer 0.2 parts, UV5411 anti-u...

Embodiment 3

[0054] (1) In parts by weight, the nylon 6 mixture (the ratio of medium viscosity nylon 6 and high viscosity nylon 6 is 2:1, the viscosity value of medium viscosity nylon 6 is 2.7, and the viscosity value of high viscosity nylon 6 is 3.2 ), antistatic agent (Sanyo Chemical’s Pelestat 6500), low-volatile matter adsorbent (nano-silica, acicular zeolite molecular sieve, and sepiolite in a mass ratio of 1.5:1:0.5), enzymatic decomposing enzyme (Japan ECO Co., Ltd. model ECO‐E decomposing enzyme), nano photocatalyst (Co., Ltd. Longinus model KV‐1N photocatalyst) were dried separately for use.

[0055] (2) In parts by weight, 76.8 parts of dried nylon 6, 5 parts of cycloolefin copolymer (COC), 3 parts of compatibilizer, 2.2 parts of low volatile matter adsorbent, antioxidant (antioxidant Agent 1098, Antioxidant 168 and Antioxidant H10 are mixed according to the mass ratio of 0.2:0.1:0.1) 0.4 parts, SAG-005 heat stabilizer 0.2 parts, UV234 anti-ultraviolet auxiliary agent 0.3 parts, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com