A kind of non-sulfide mineral flotation collector and its application

A mineral flotation and non-sulfurization technology, applied in flotation, solid separation, etc., can solve the problems of poor collection performance of oleic acid, energy consumption, cost increase, poor selectivity of oleic acid, etc., to achieve energy saving, emission reduction, The effect of high recovery rate and strong dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

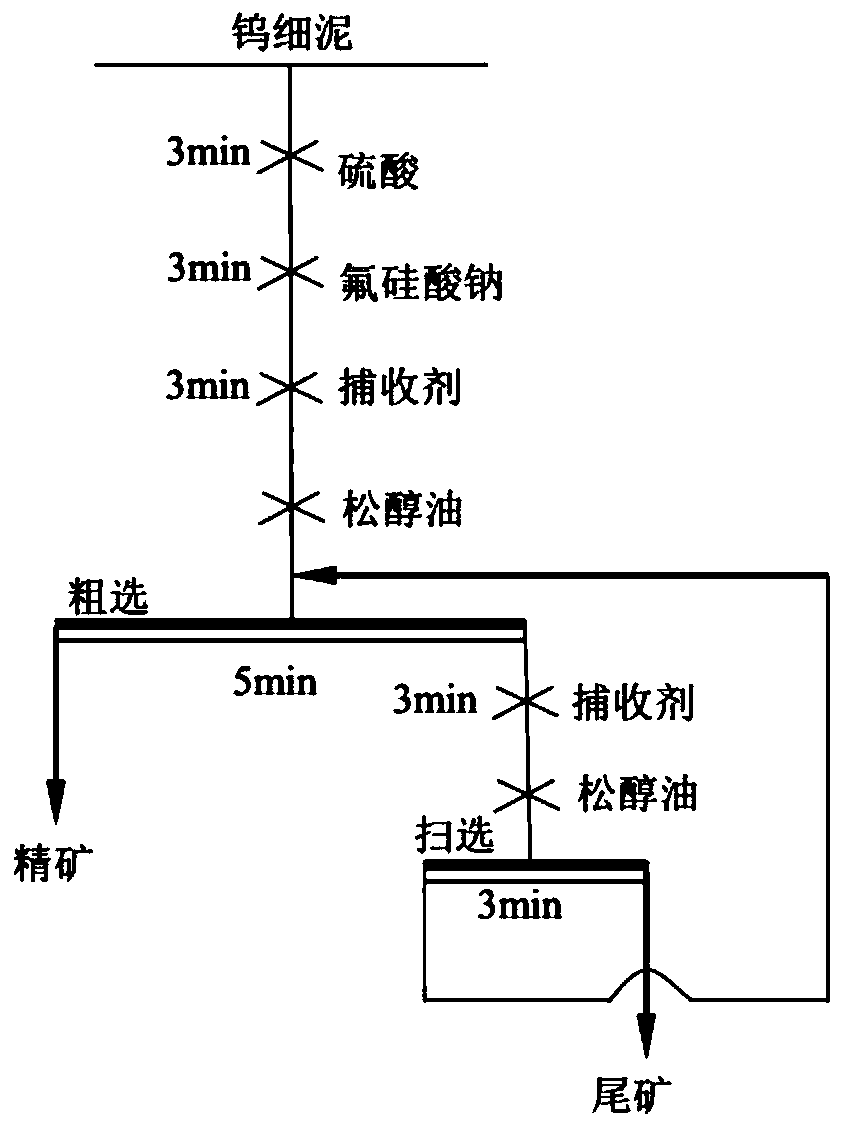

[0029] A tungsten fine mud contains scheelite and wolframite, the fine mud particle size is -74μm, accounting for 82% of the total mass of the ore, containing WO 3 The amount is 0.43%, and the main gangue minerals include quartz, mica, calcite, fluorite, etc.

[0030] use as figure 1 The rough-sweep flotation process shown recovers tungsten minerals. During the roughing process, add pulp regulator sulfuric acid and sodium fluorosilicate, the amount of sulfuric acid relative to the original ore is 150g / t, the amount of sodium fluorosilicate relative to the original ore is 200g / t, and then add the collector carboxyethylbenzene The dosage of carboxyethylphenylphosphinic acid and its salts, carboxyethylphenylphosphinic acid and its salts relative to the raw ore is 500g / t, then add the foaming agent terpineol oil, the dosage of terpineol oil relative to the raw ore is 100g / t; during the sweeping process, add collector carboxyethylphenylphosphinic acid and its salts, the amount o...

Embodiment 2

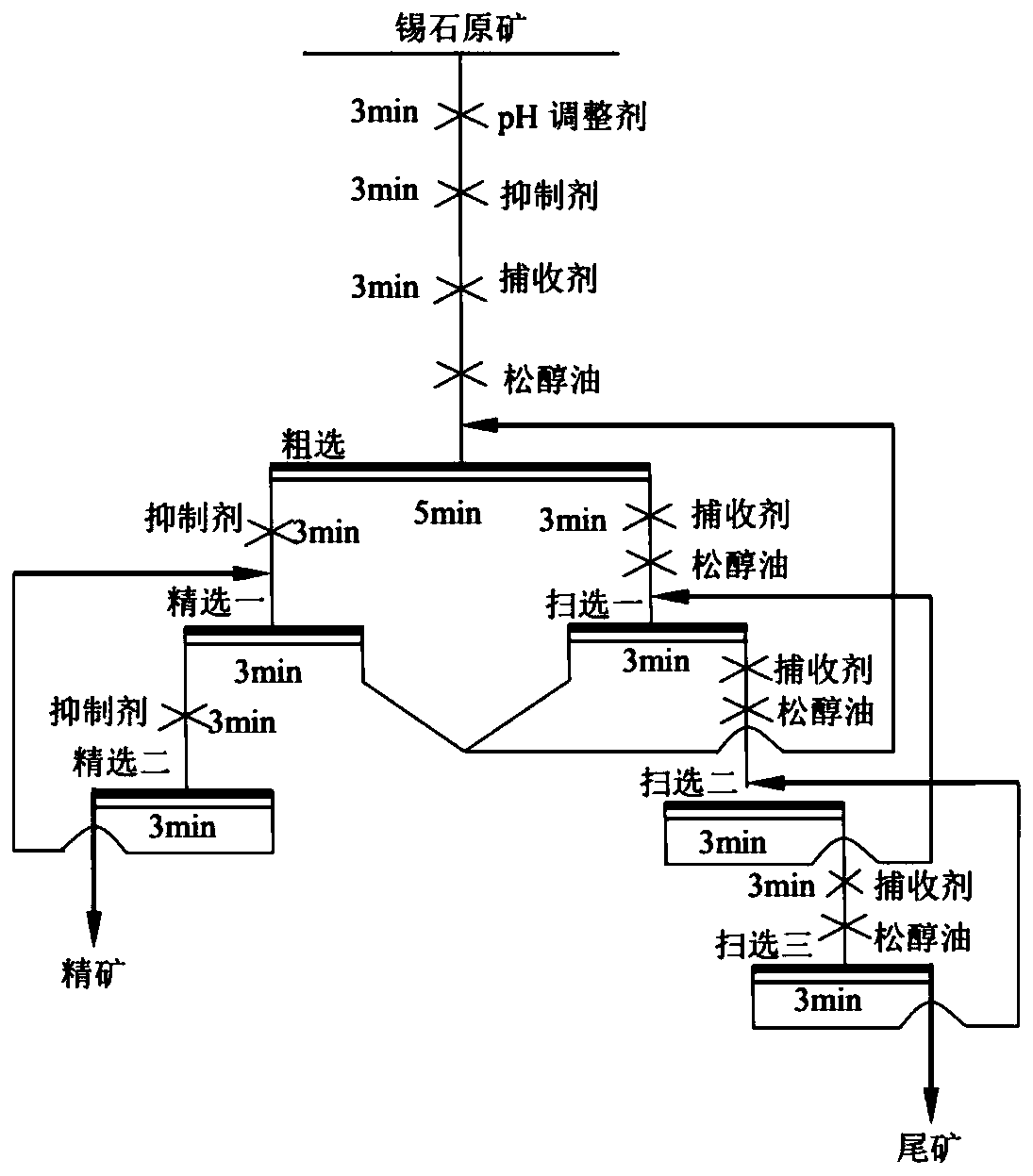

[0033] A cassiterite raw ore in Yunnan Province was selected as the raw material. The tin grade in the raw ore was 0.31%, and more than 70% of the cassiterite in the raw ore was distributed in the -45μm particle size. The gangue minerals in cassiterite mines include quartz, fluorspar, calcite, feldspar, mica, tremolite and a large number of clay minerals.

[0034] use as figure 2The shown one rough three sweep two fine flotation process recovery cassiterite. During the roughing process, add gangue mineral inhibitor sodium carboxymethyl cellulose and sodium silicate, the amount of sodium carboxymethyl cellulose relative to the original ore is 150g / t, and the amount of sodium silicate relative to the original ore is 150g / t , then add the collector carboxyethylphenylphosphinic acid and its salts, the amount of carboxyethylphenylphosphinic acid and its salts relative to the original ore is 1500g / t, then add the foaming agent terpineol oil, The amount of pine alcohol oil relativ...

Embodiment 3

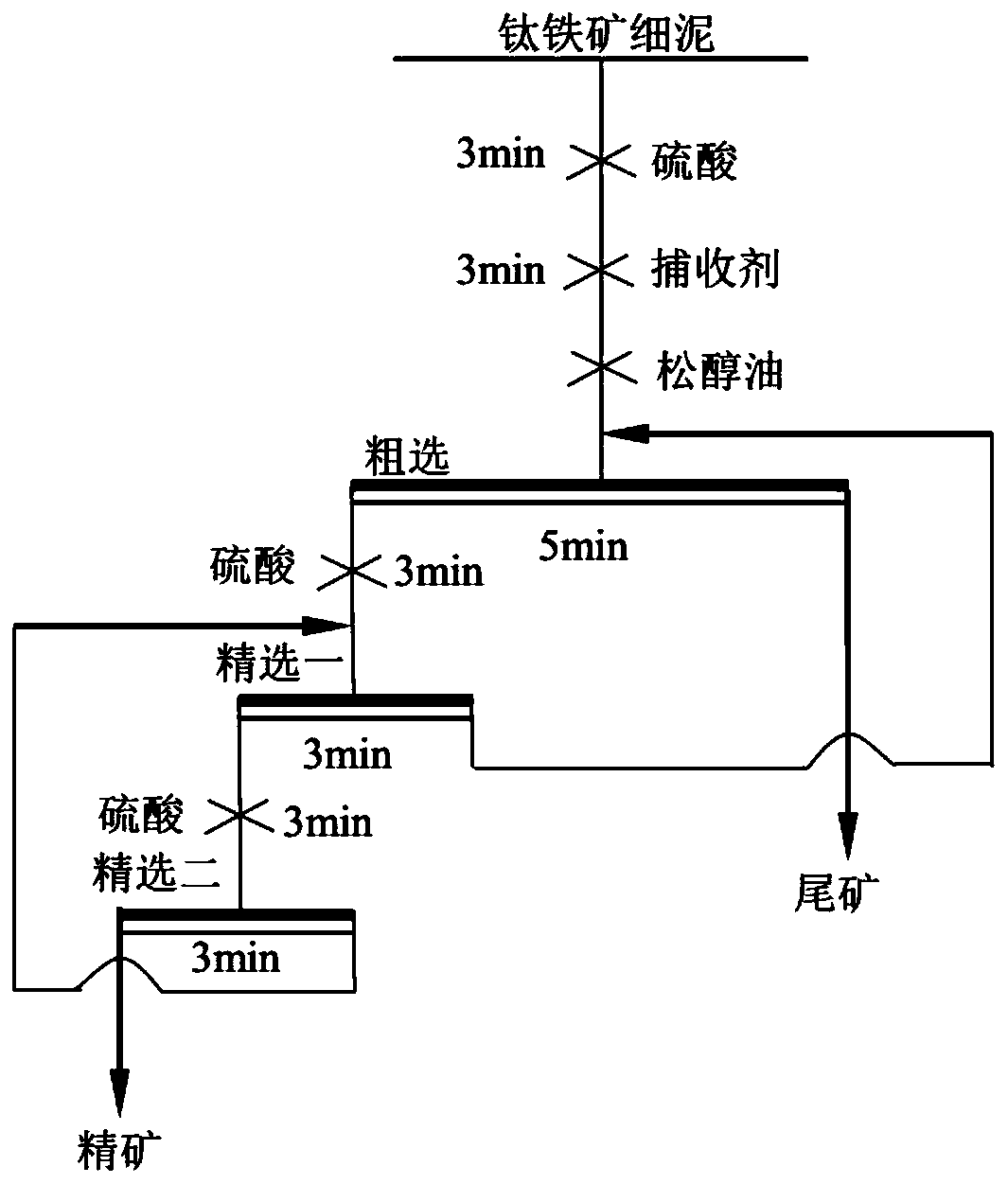

[0037] A certain ilmenite fine mud, with a particle size of -74μm, accounts for 70% of the total mass of the ore, and contains 7.23% of titanium dioxide. Titanium dioxide is mainly distributed in ilmenite particles and is the main recovered mineral. Gangue minerals mainly include feldspar, olivine, chlorite, calcite, mica, serpentine and so on.

[0038] use as image 3 Shown is a rough and two fine flotation process to recover ilmenite. During the roughing process, add sulfuric acid as a pulp regulator, the amount of sulfuric acid relative to the raw ore is 1500g / t, and then add collector carboxyethylphenylphosphinic acid and its salts, carboxyethylphenylphosphinic acid and its The amount of salt relative to the original ore is 1000g / t, and then add foaming agent terpineol oil, the amount of terpineol oil relative to the original ore is 120g / t; The dosage is 800g / t, and it is selected twice; during the flotation process, the temperature of the pulp is maintained at about 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com