Cutting method of large riser sprue runner for large high-temperature alloy casting

A technology of superalloy and cutting method, which is applied in the field of cutting large riser runners of large superalloy castings, can solve the problems of difficult parts clamping and operation, inconvenient operation of cutting machines, and increased cutting costs, so as to avoid the influence of large heat. The formation of the area, avoiding the generation of oxides, and improving the cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

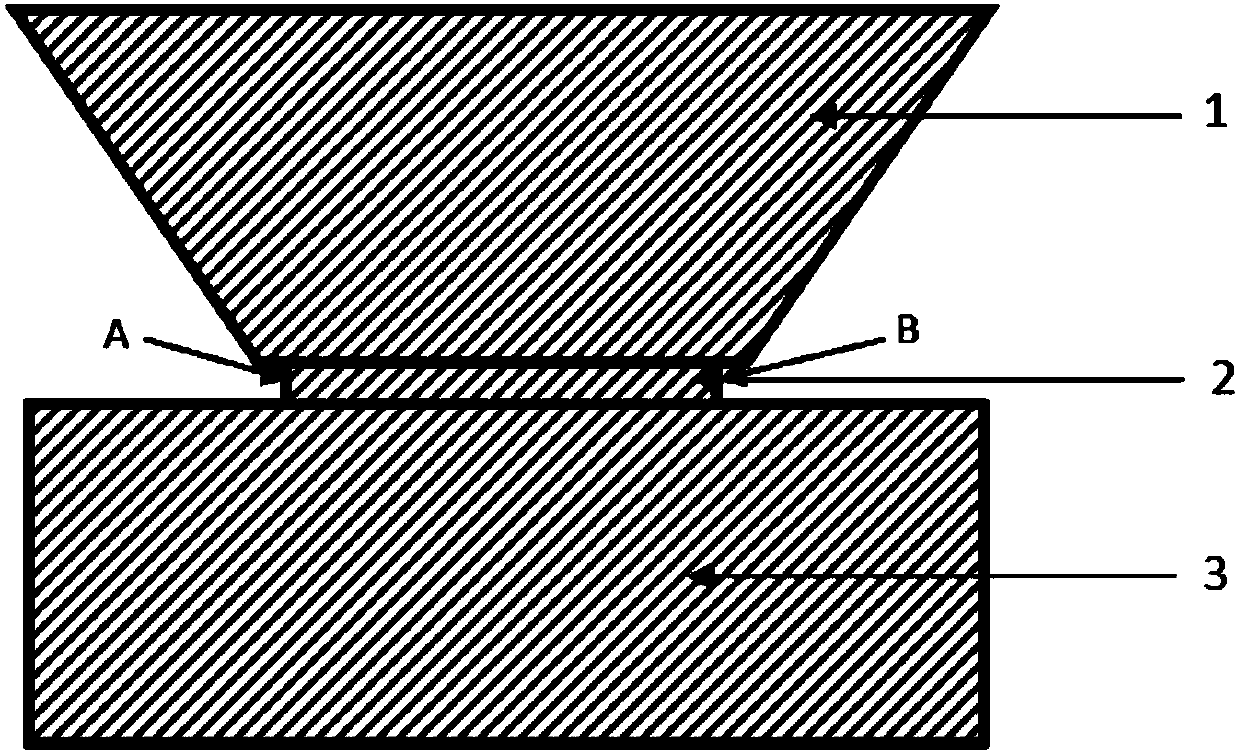

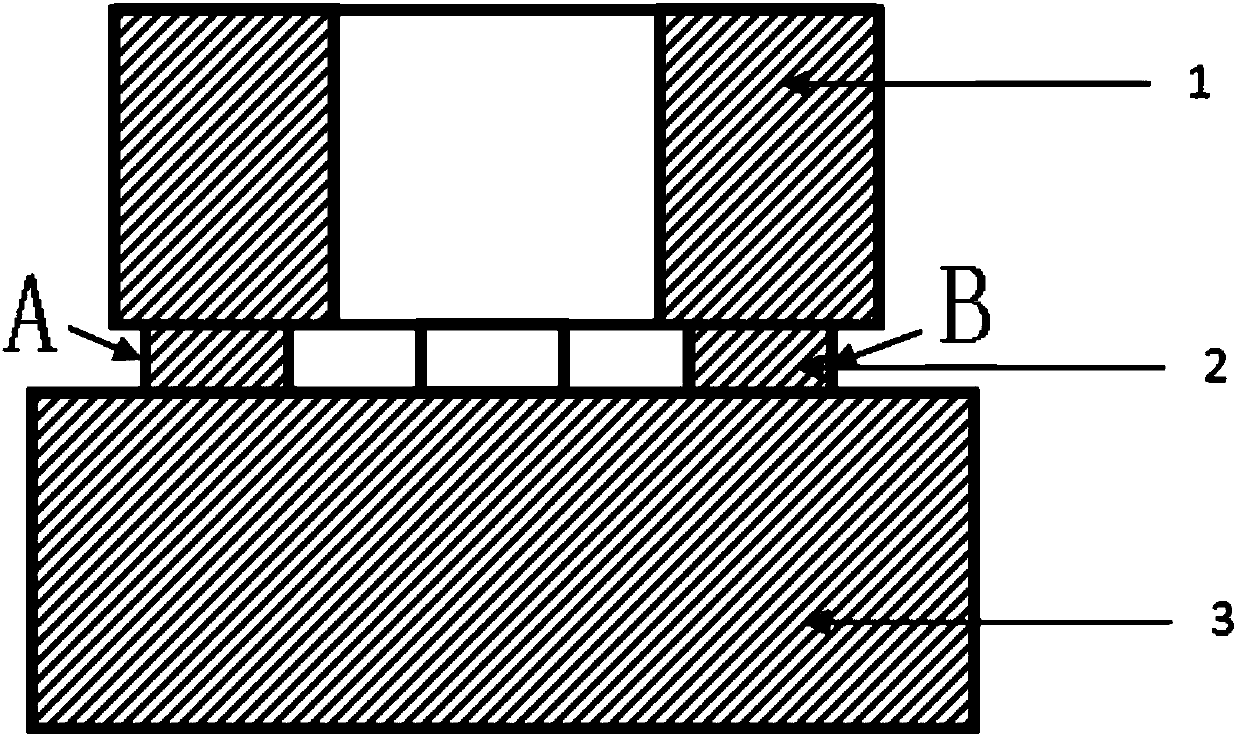

[0020] The diameter of the large superalloy annular casting is 1200mm, and the riser sprue is distributed. After unpacking, the temperature of the casting is 500°C. After the casting is cooled to 180°C, use a crane to reposition it laterally so that the cutting direction is perpendicular to the ground. Fix the two sides of the casting in contact with the ground with wooden blocks. Choose to use DC arc welding equipment with a working current of 500A, select nickel-based alloy electrodes, and select the diameter of the cutting electrodes to be more than 4mm. Fix the gas tube of the argon gas cylinder to the equipment gun of the arc welding machine, and the nozzle of the gas tube is in the same direction as the welding wire. At the same time, turn on the arc welding equipment and the argon gas cylinder, wherein the current of the electric welding equipment is adjusted to 300A, and the outlet pressure of the argon gas cylinder is adjusted to 1.0MPa. During the cutting process, ...

Embodiment 2

[0022] A large high-temperature alloy precision round cake casting, the diameter of the part is 1000mm, and the riser is centralized. After unpacking, the temperature of the casting is 450°C. After the casting is cooled to 200°C, use a crane to reposition it laterally so that the cutting direction is perpendicular to the ground. Fix the two sides of the casting in contact with the ground with wooden blocks. Choose to use DC arc welding equipment with a working current of 500A, select nickel-based alloy electrodes, and select the diameter of the cutting electrodes as 5mm. Fix the gas tube of the argon gas cylinder to the equipment gun of the arc welding machine, and the nozzle of the gas tube is in the same direction as the welding wire. At the same time, turn on the arc welding equipment and the argon gas cylinder, wherein the current of the electric welding equipment is adjusted to 320A, and the outlet pressure of the argon gas cylinder is adjusted to 1.0MPa. During the cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com