Rust resistance type starch-base water reducer and preparation method thereof

A water-reducing agent and starch-based technology, which is applied in the field of starch-based water-reducing agent and its preparation, can solve the problem of the toxicity of the small-molecule steel rust inhibitor, the incompatibility of water-reducing and rust-inhibiting effects, and the mixing of concrete admixtures. Low volume and other problems, to achieve excellent anti-rust function, reduce application costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

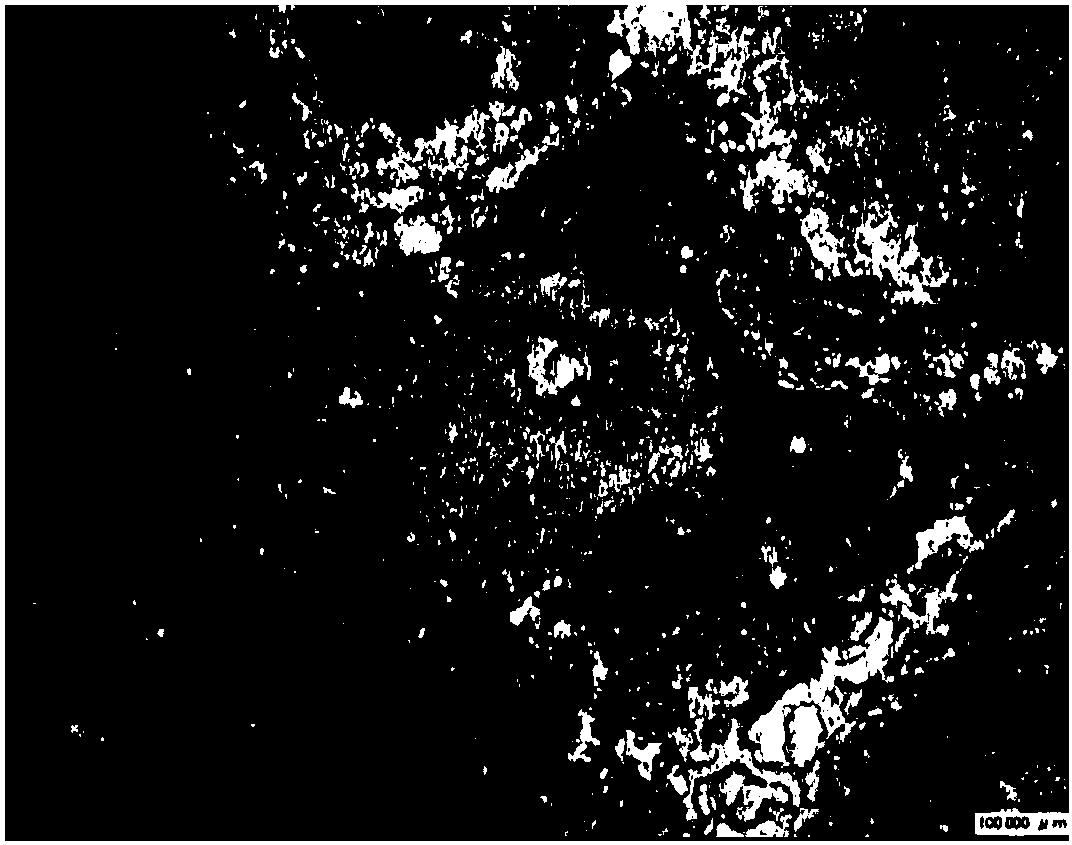

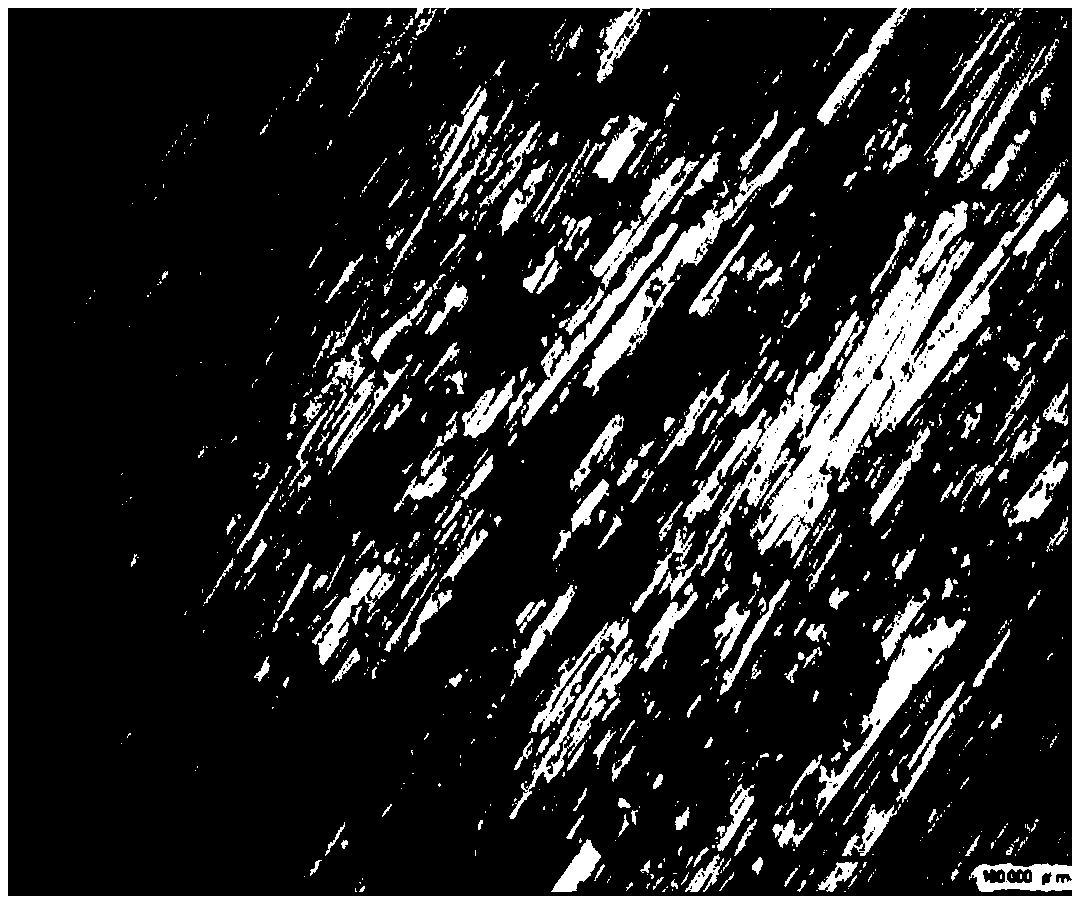

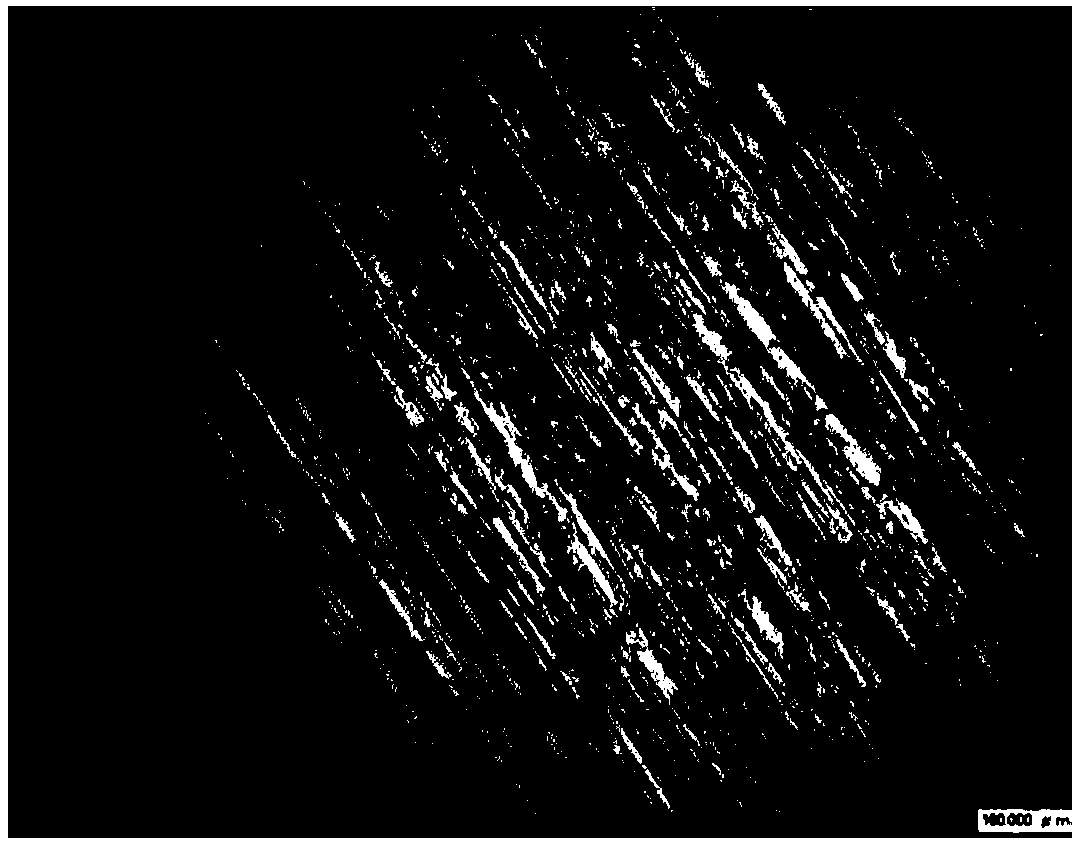

Image

Examples

Embodiment 1

[0034] Add 50g of industrial-grade common cornstarch and 75g of water to make starch milk containing 40% starch, add 5g of 98% concentrated sulfuric acid, then heat in a water bath for hydrolysis reaction, stop heating after 2h, cool down to room temperature without neutralization, and keep the residual sulfuric acid. Use vacuum filtration, dry and store at low temperature. Add 5 g of thioglycolic acid dropwise to the obtained acid-thinned starch, and mix well. Maleic anhydride 2.5g, sulfamic acid (NH 3 SO 3 ) 1.5g mixed and ground, then added to the mixture of the above-mentioned acid-thinned starch and thioglycolic acid, then added 10g of water and mixed fully, stirred evenly, synthesized by a semi-dry method, put it in a 50°C oven for 2 hours, and heated up to After reacting at 100°C for 4 hours, the starch sample was taken out, dried and ground to obtain a starch-based water reducer with the function of inhibiting steel corrosion.

Embodiment 2

[0036] Add 50g of industrial-grade common corn starch and 75g of water to make starch milk containing 40% starch, add 2.5g of 98% concentrated sulfuric acid, then heat in a water bath for hydrolysis reaction, stop heating after 2h, cool down to room temperature without neutralization, and keep the residual sulfuric acid , vacuum filtered, dried and stored at low temperature. Add 5 g of thioglycolic acid dropwise to the obtained sulfonated starch, and mix well. Mix and grind 5g of maleic anhydride and 4.5g of sulfamic acid, then add to the above mixture of acid-thyzed starch and thioglycolic acid, and then add 10g of water to fully mix, stir evenly, synthesize by semi-dry method, and put in an oven at 50°C React in medium for 2 hours, raise the temperature to 100°C, react for 4 hours, take out the starch sample, dry and grind to obtain the starch-based water reducer with the function of inhibiting steel corrosion.

Embodiment 3

[0038] Add 50g of industrial-grade common cornstarch and 75g of water to make starch milk containing 40% starch, add 1g of 98% concentrated sulfuric acid, then heat in a water bath for hydrolysis reaction, stop heating after 2h, cool down to room temperature without neutralization, and keep the residual sulfuric acid. Use vacuum filtration, dry and store at low temperature. Add 7.5 g of thioglycolic acid dropwise to the obtained acid-thinned starch, and mix well. Mix and grind maleic anhydride 5g and sulfamic acid 10.5g, then use semi-dry method to synthesize, put it in a 60°C oven for 2 hours, heat up to 110°C, react for 4 hours, take out the starch sample, dry and grind to obtain Starch-based superplasticizer with steel bar corrosion function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com