Surface plasma resonance sensor based on quantum weak measurement and method for measuring refractive index of metal surface medium

A surface plasmon, weak measurement technology, applied in the technical field of quantum optics technology, can solve the problems such as the difficulty of further improving the sensitivity, the low sample to be tested, and the difficult space for improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

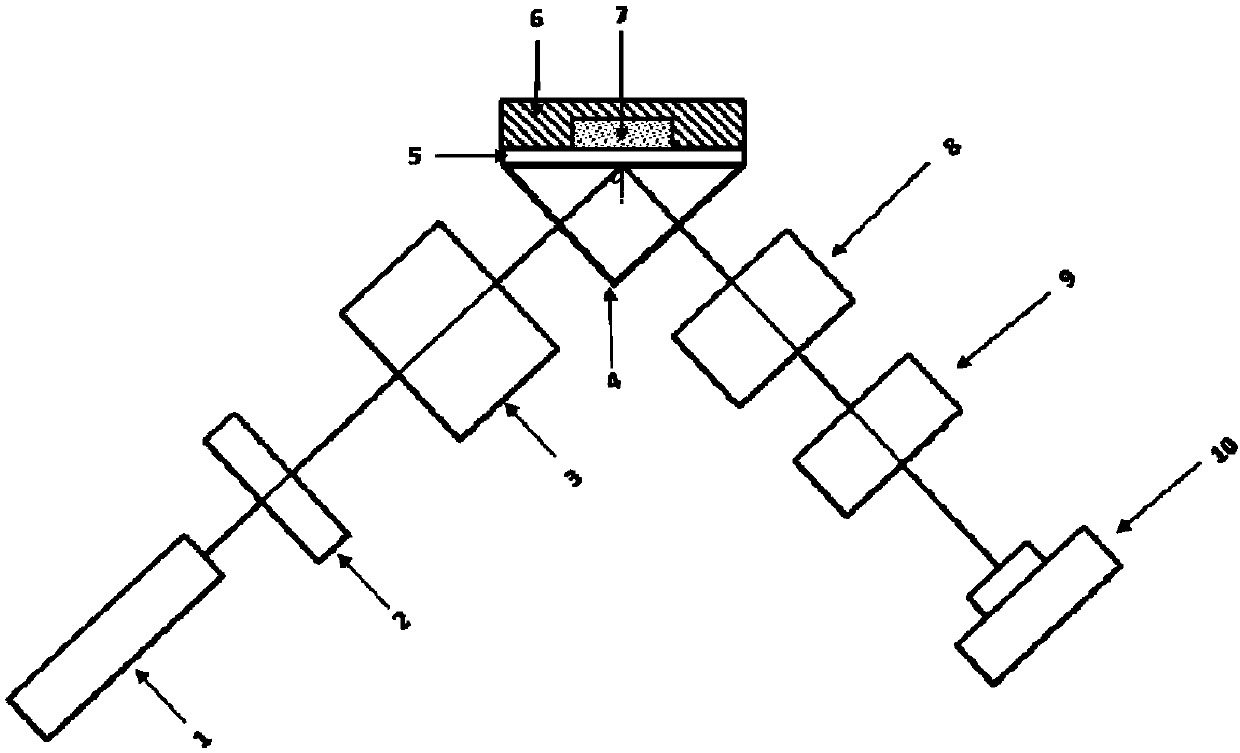

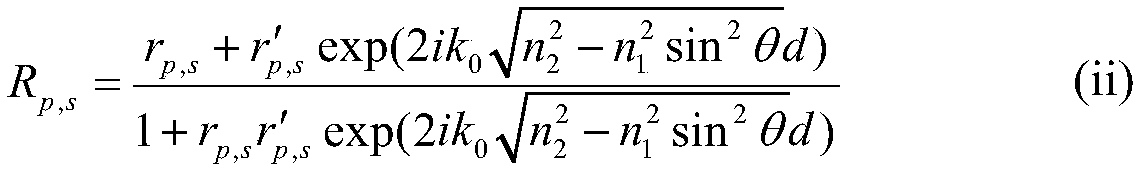

[0070] The surface plasmon sensor based on quantum weak measurement provided by this embodiment has a structure such as figure 1 As shown, the surface plasmon sensor includes a light emitting device, a polarization state generator 3 , a prism 4 coated with a metal film 5 , a sample coupler 6 containing a sample 7 , a polarization state selector and a photodetector 10 . The light emitting device is composed of a light source generator 1 and an energy regulator 2, wherein the light source generator 1 is a collimated laser, and the energy regulator 12 is a half-wave plate. The first polarizer 3 is a Glan laser polarizing prism (BK7). Prism 4 is a right-angled triangular prism. The metal film 5 is a gold film, and one side of the metal film 5 is in contact with the sample 7 . The polarization state selector is composed of a phase compensation system 8 and a polarizer 9, the phase compensation system 8 is located in front of the polarizer 9, the phase compensation system 8 is a p...

Embodiment 2

[0073] This embodiment is based on the quantum weak measurement technology, and adopts the surface plasmon sensor based on the quantum weak measurement provided in Example 1 to measure the refractive index of the NaCl solution sample. The steps are as follows:

[0074] (S1) Prepare 10 parts of NaCl solutions with a known concentration of 0-0.23% (mass percentage); the solution with a concentration of 0 is deionized water, and it is used as a standard solution.

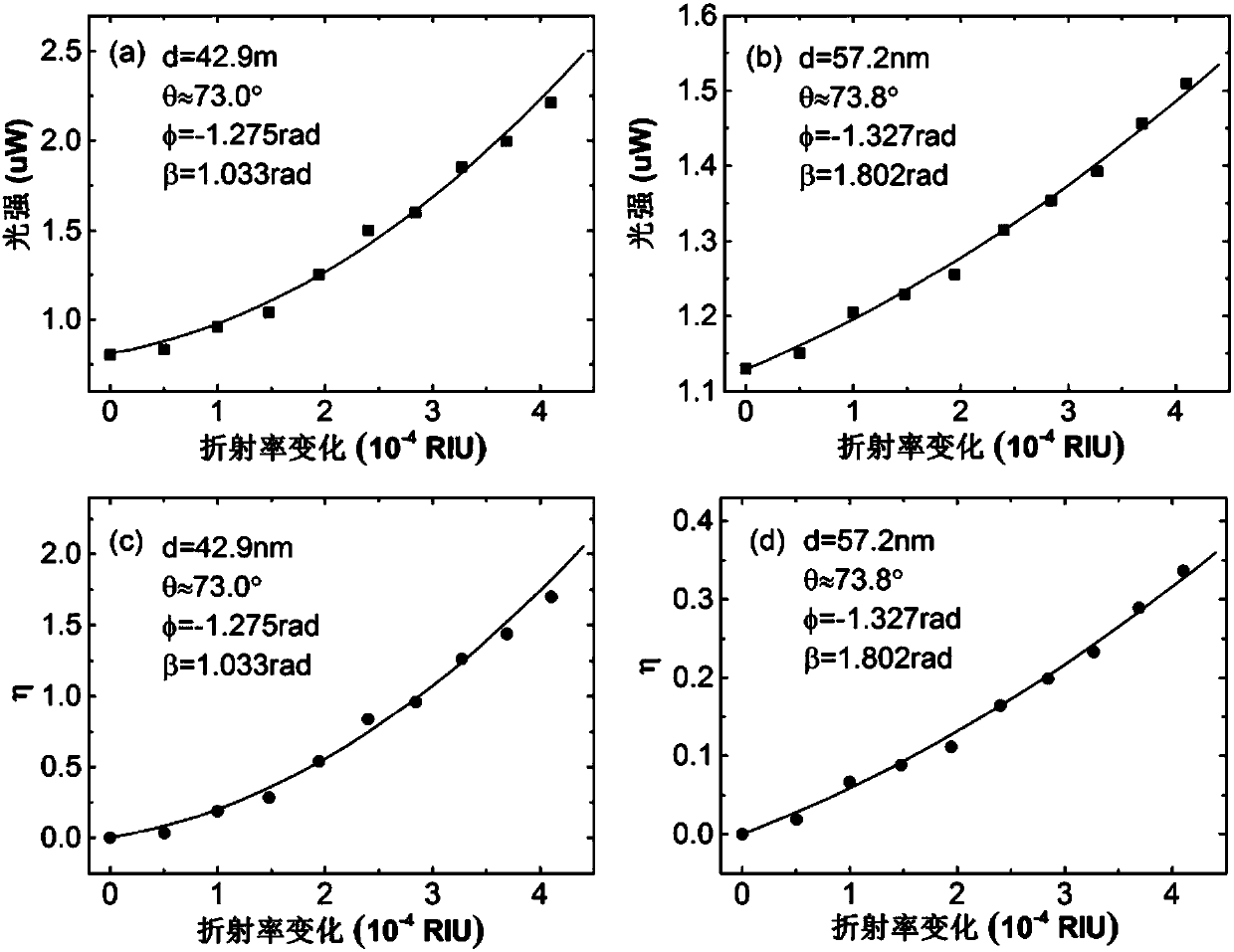

[0075] (S2) Put deionized water into the sample coupler; turn on the light source generator 1, and the laser light emitted by it enters the prism at an incident angle θ=73.0° close to the resonance angle through the energy regulator 2 and the polarization state preparation device 3 -gold film-sample interface to be tested, the reflected light passes through the phase compensation system 8 (phase compensation phi=-1.275rad) and the polarizer 9, and is received by the photodetector 10; Form angle α=0.084rad; Adjust the p...

Embodiment 3

[0096] This embodiment is based on the quantum weak measurement technology, and adopts the surface plasmon sensor based on the quantum weak measurement provided in Example 1 to measure the refractive index of the NaCl solution sample. The steps are as follows:

[0097] (S1) Prepare 10 parts of NaCl solutions with a known concentration of 0-0.23% (mass percentage); the solution with a concentration of 0 is deionized water, and it is used as a standard solution.

[0098] (S2) Put deionized water into the sample coupler; turn on the light source generator 1, and the laser light emitted by it enters the prism at an incident angle θ=73.8° close to the resonance angle through the energy regulator 2 and the polarization state preparation device 3 -gold film-sample interface to be measured, the reflected light passes through the phase compensation system 8 (phase compensation φ=-1.327rad) and the polarizer 9, and is received by the photodetector 10; Form angle α=0.084rad; Adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com