A kind of manufacturing method of passivated contact solar cell

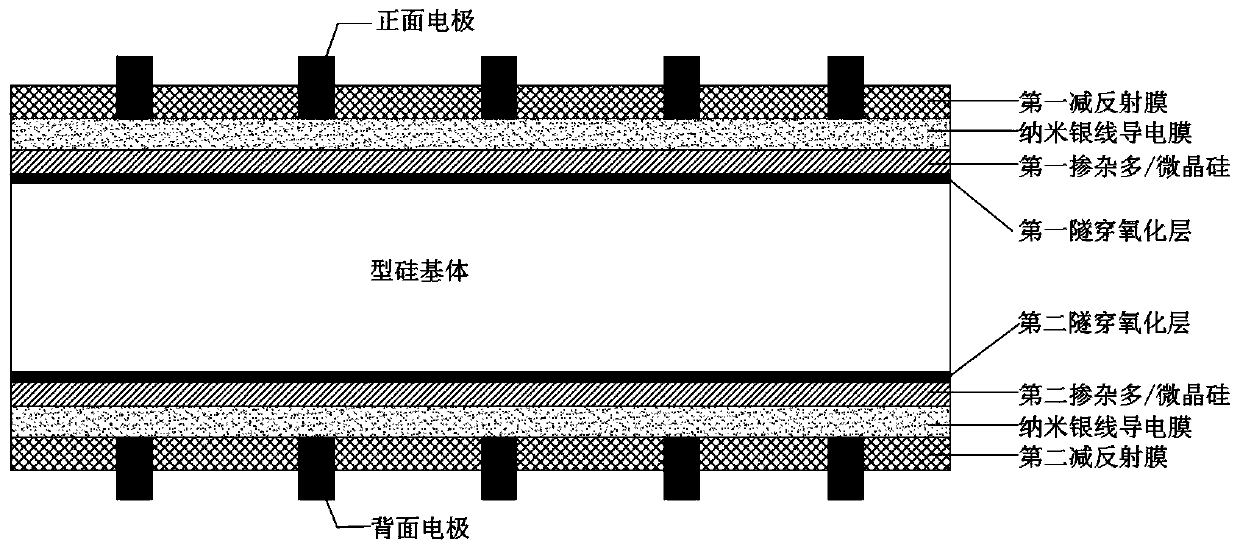

A technology of a solar cell and a manufacturing method, applied in the field of solar cells, can solve the problems of reduction, high process control and environmental requirements, difficult manufacturing cost of a transparent conductive film, etc., achieves simple process, advantages of light transmittance and electrical conductivity, and reduces light The effect of occlusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

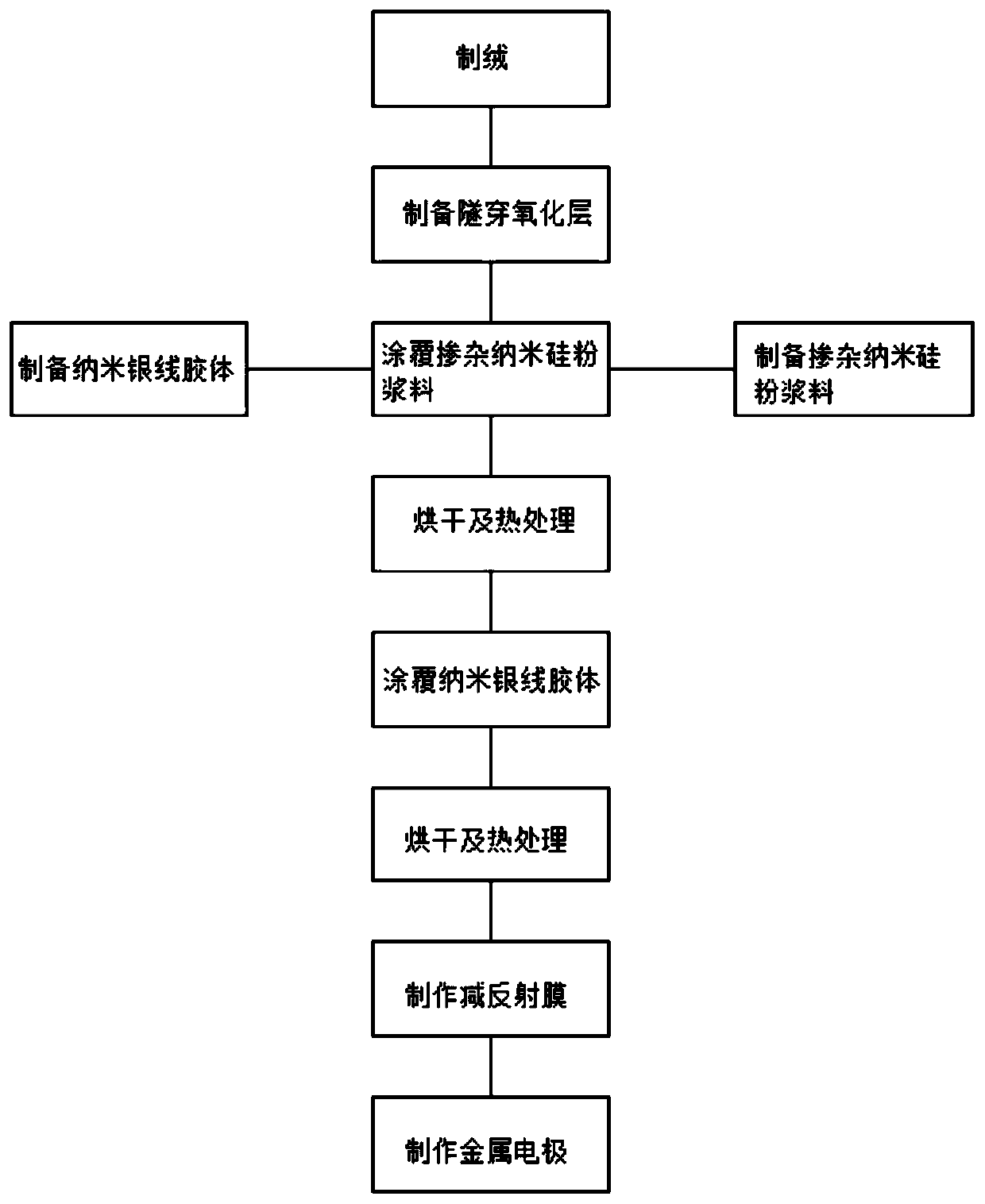

[0038] A method for making a passivated contact solar cell, comprising the following steps:

[0039] Step 1: Texture the P-type monocrystalline silicon wafer in NaOH hot solution, and wash to remove the dirt and damaged layer on the surface of the silicon wafer, and form a pyramidal light-trapping structure on the surface.

[0040] Step 2: Place the textured silicon wafer in ozone water with an ozone concentration of 50 ppm for 15 minutes to form a 1.2nm dense silicon oxide film on the surface of the silicon wafer.

[0041] Step 3: Prepare doped nano silicon powder slurry and nano silver wire colloid respectively.

[0042] The slurry doped with nano-silicon powder includes: ① Nano-crystalline silicon powder, with a mass fraction of 30% and a particle size of about 100nm. ②A slurry doped with nano-silicon powder is doped with boric acid, and the mass fraction of boron is 10^-7; another slurry doped with nano-silicon powder is doped with phosphoric acid, and the mass fraction o...

Embodiment 2

[0051] Step 1: forming an inverted pyramid structure on the surface of the N-type single crystal silicon wafer by catalytic chemical etching with nanometer metal particles.

[0052] Step 2: Place the textured silicon wafer in a thermal oxidation furnace in an oxygen atmosphere at 800° C. for 10 minutes to form a 2nm dense silicon oxide film on the surface.

[0053] Step 3: Prepare doped nano silicon powder slurry and nano silver wire colloid respectively.

[0054] The slurry doped with nano-silicon powder includes: ① Nano-crystalline silicon powder, with a mass fraction of 70% and a particle size of about 300nm. ② One kind of doped nano-silicon powder slurry is doped with boric acid, and the mass fraction of boron element is 10^-5; the other doped nano-silicon powder slurry is doped with phosphoric acid, and the mass fraction of phosphorus element is 10 ^-5. ③ According to the performance of the slurry, add the organic additive terpineol in proportion.

[0055] The nano sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com