A kind of ferric oxide with pomegranate structure and its preparation method and application as lithium ion negative electrode active material

A ferric oxide, pomegranate-type technology, applied in structural parts, battery electrodes, secondary batteries, etc., can solve problems such as poor conductivity and poor cycle stability, and achieve the effects of buffering volume expansion, excellent rate performance, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

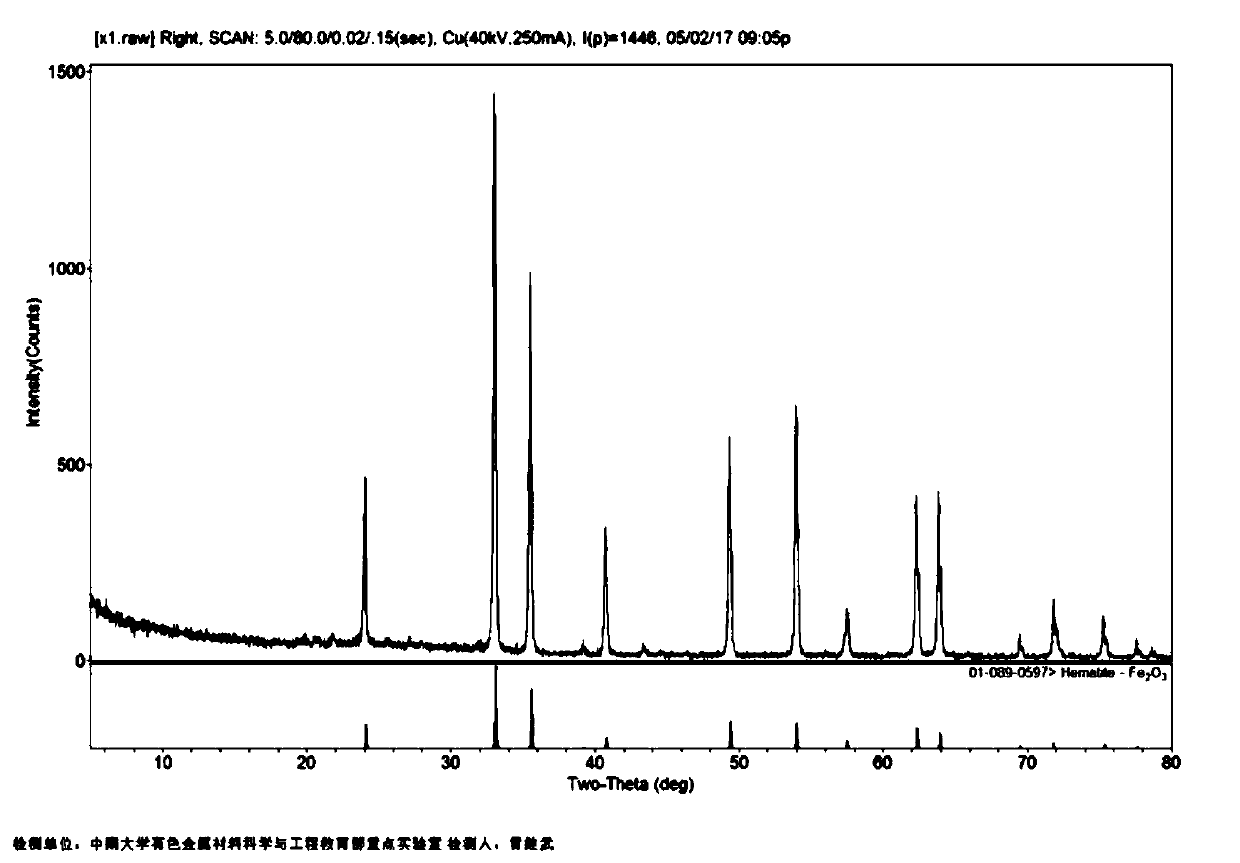

Image

Examples

Embodiment 1

[0048] ①Put 4.005g of polyferric sulfate into a high temperature resistant porcelain boat, and put the porcelain boat into the muffle furnace.

[0049] ②Set the heating rate of the muffle furnace to 10°C / min, the heating time to 80 minutes, and the holding time to 220 minutes to obtain 1.388 g of ferric oxide.

[0050] ③ Grind and mix 70mg of ferric oxide and 20mg of conductive carbon black powder evenly, then stir at room temperature for 0.5-1h, then add 10mg of polyvinylidene fluoride and stir for 0.5-1h at room temperature to obtain negative electrode slurry, and use a coating machine to prepare the negative electrode The slurry was coated on a copper foil, dried in a vacuum oven at 60° C. for 24 hours, and sliced to obtain a negative electrode of ferric oxide.

[0051] ④Pair the ferric oxide negative electrode obtained in ③ with lithium metal, and use 1mol L -1 LiPF 6 The EC / DMC (volume ratio 1:1) solution was used as the electrolyte, and a CR2016 lithium-ion button ba...

Embodiment 2

[0053] ① Take 4.007g of polyferric sulfate and put it into a high temperature resistant porcelain boat, and put the porcelain boat into the muffle furnace.

[0054] ②Set the heating rate of the muffle furnace to 10°C / min, the heating time to 60 minutes, and the holding time to 220 minutes to obtain 2.359 g of ferric oxide.

[0055] ③ Grind and mix 70mg of ferric oxide and 20mg of conductive carbon black powder evenly, then stir at room temperature for 0.5-1h, then add 10mg of polyvinylidene fluoride and stir for 0.5-1h at room temperature to obtain negative electrode slurry, and use a coating machine to prepare the negative electrode The slurry was coated on a copper foil, dried in a vacuum oven at 60° C. for 24 hours, and sliced to obtain a negative electrode of ferric oxide.

Embodiment 3

[0057] ① Take 4.003g of polyferric sulfate and put it into a high temperature resistant porcelain boat, and put the porcelain boat into the muffle furnace.

[0058] ②Set the heating rate of the muffle furnace to 10°C / min, the heating time to 90 minutes, and the holding time to 220 minutes to obtain 1.438 g of ferric oxide.

[0059] ③ Grind and mix 70mg of ferric oxide and 20mg of conductive carbon black powder evenly, then stir at room temperature for 0.5-1h, then add 10mg of polyvinylidene fluoride and stir for 0.5-1h at room temperature to obtain negative electrode slurry, and use a coating machine to prepare the negative electrode The slurry was coated on a copper foil, dried in a vacuum oven at 60° C. for 24 hours, and sliced to obtain a negative electrode of ferric oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com