Molybdenum selenide nanosheet/nitrogen-doped carbon core-shell-structure composite material and preparation method and application thereof

A nitrogen-doped carbon, composite material technology, applied in catalyst activation/preparation, chemical instruments and methods, nanotechnology, etc., can solve the problems of limiting molybdenum selenide, poor electrical conductivity, etc., achieving good synergistic enhancement effect and excellent performance , the effect of large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

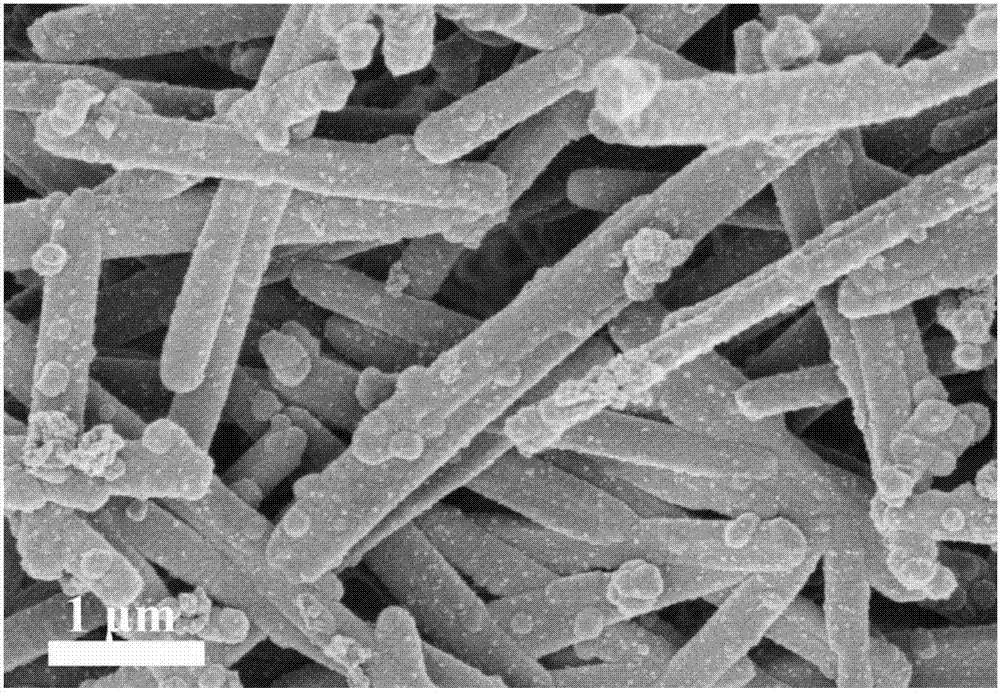

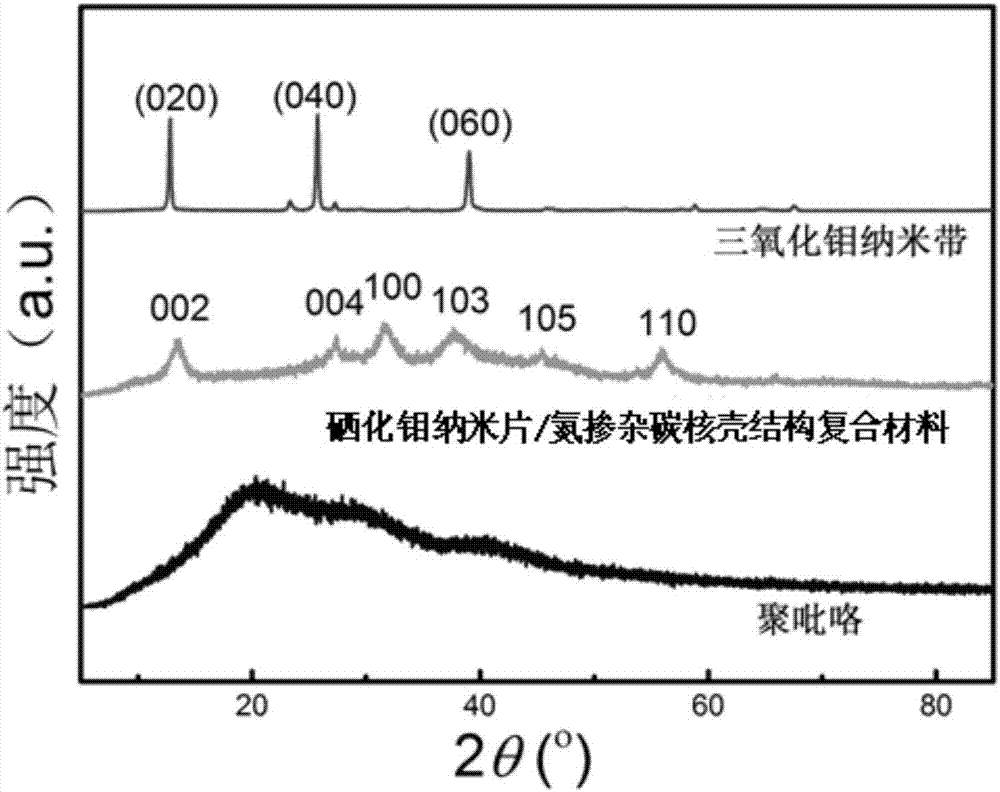

[0031] (1) Add 1.21g sodium molybdate and 0.6g sodium chloride to 60mL deionized water to obtain a solution, continue stirring for 10min to obtain a uniform dispersion, add 3mol / L hydrochloric acid solution to adjust the pH value to 1, and transfer to a hydrothermal kettle The hydrothermal reaction was carried out in an oven, the reaction temperature was 180°C, and the reaction time was 24 hours. After the reaction kettle was cooled to room temperature, the obtained dispersion was subjected to suction filtration to separate the light blue precipitate, and the obtained solid was washed with deionized water. , dried in an oven at 60° C. for 24 hours to obtain molybdenum trioxide nanobelts.

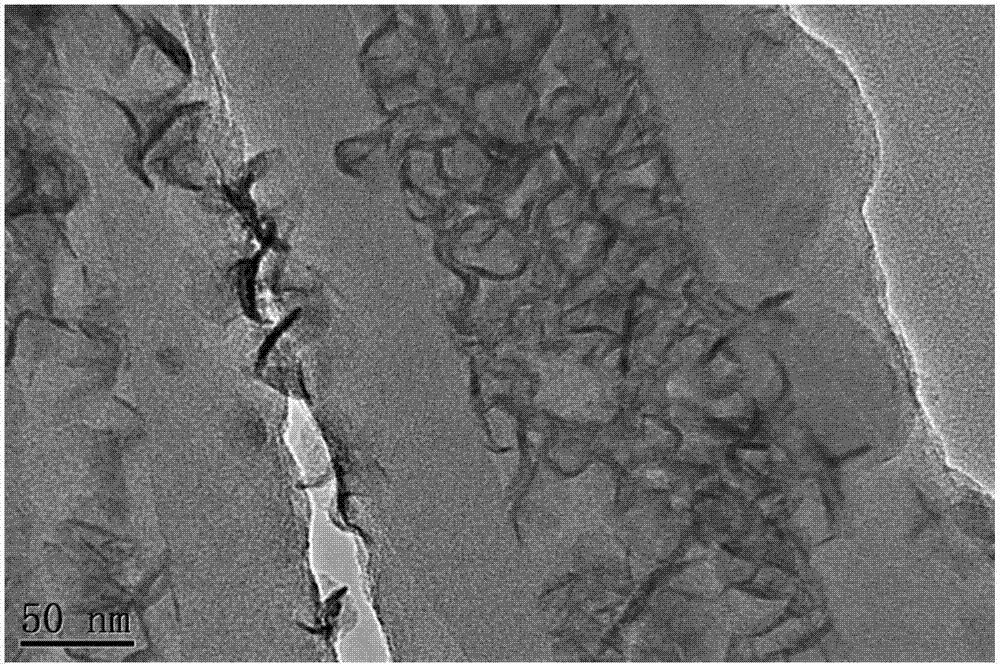

[0032] (2) Add 40 mg of molybdenum trioxide nanobelts in step (1) to a 250 mL flask, add 80 ml of deionized water, stir to make molybdenum trioxide evenly dispersed in deionized water to obtain a dispersion, and use a pipette to measure 200 μL of pyrrole (0.00288mol) was added to the above f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com