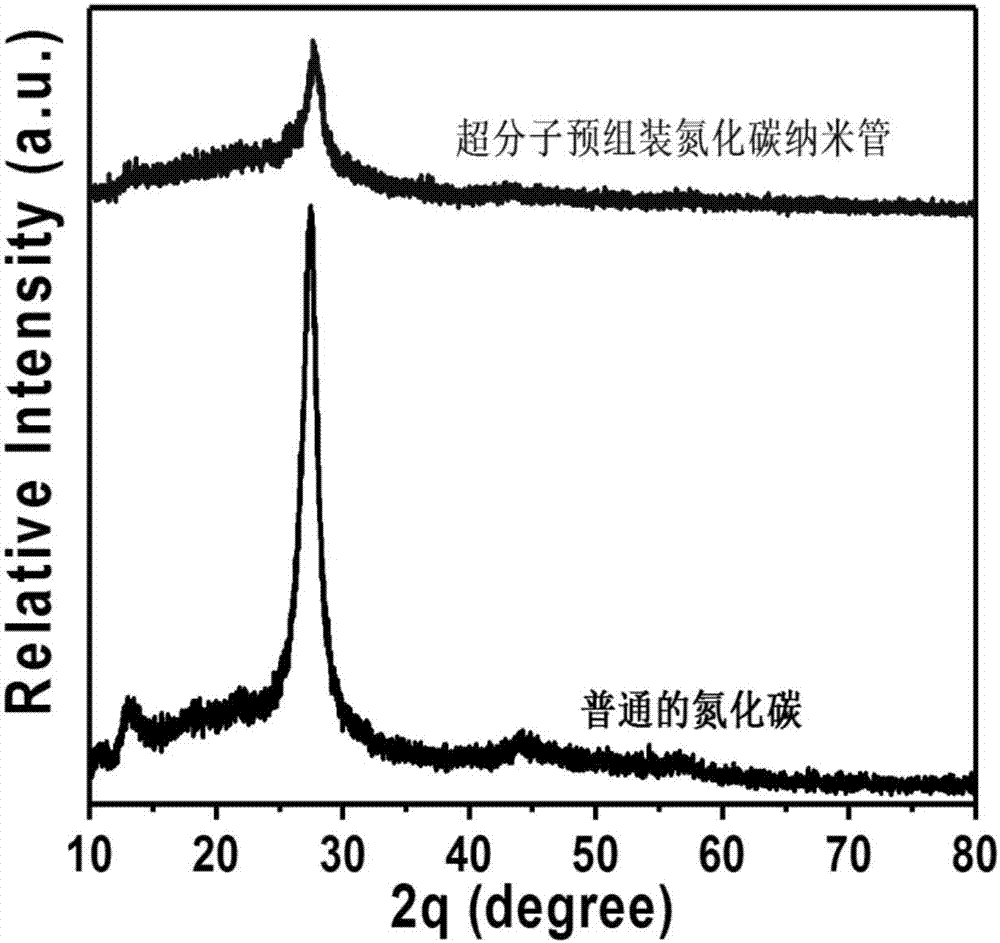

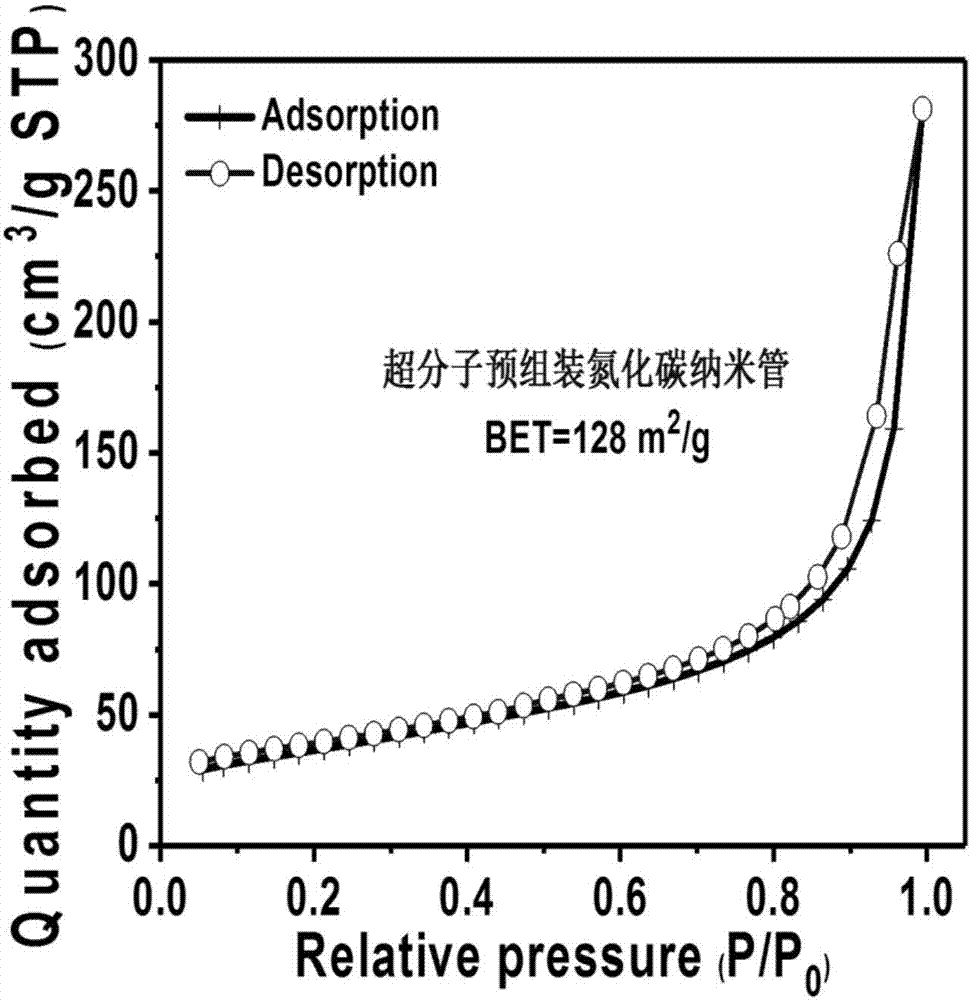

Preparation method for supermolecular pre-assembled carbon nitride nanotube photocatalyst

A photocatalyst and supramolecular technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low degradation efficiency of high-concentration organic dyes and low utilization rate of visible light, etc., to achieve beneficial Large-scale preparation, the preparation method is simple and easy, and the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

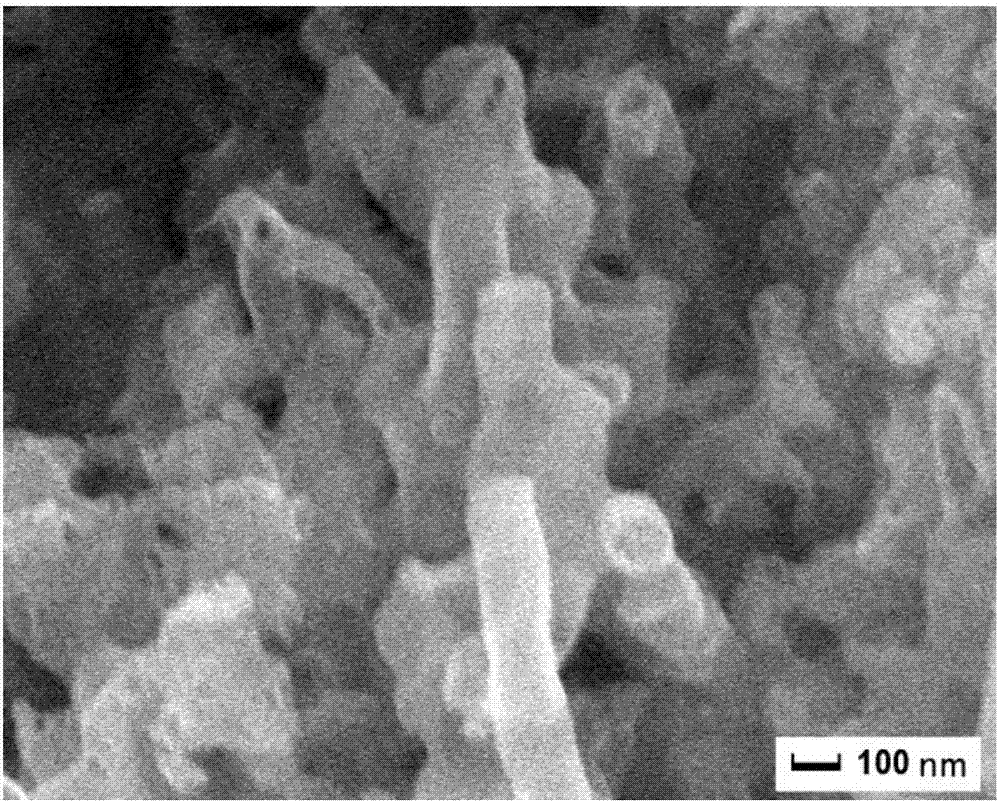

[0021] Embodiment 1: the preparation method of the supramolecular pre-assembled carbon nitrogen nanotube photocatalyst of the present invention, specifically comprises the following steps:

[0022] Step 1: Put 2 g of melamine and 3 g of hydroxylamine chloride in a 40 mL beaker filled with deionized water, and disperse with magnetic stirring at room temperature for 30 minutes to obtain a mixed dispersion;

[0023] Step 2: Transfer the obtained mixed dispersion to a 50mL hydrothermal reaction kettle, put it in a constant temperature oven at 140°C for 12 hours, then let the reaction kettle cool down to room temperature naturally, and centrifuge at 11000-13000 rpm for 1 -3min, wash with deionized water and ethanol three times each, and dry in a constant temperature oven at 60°C to obtain a rod-shaped supramolecular intermediate;

[0024] Step 3: Weigh four portions of 1.5g supramolecular intermediates and place them in four crucibles (all four crucibles are covered), place the fou...

Embodiment 2

[0031] Embodiment 2: the preparation method of the supramolecular pre-assembled carbon nitrogen nanotube photocatalyst of the present invention, specifically comprises the following steps:

[0032] Step 1: Put 0.8g of melamine and 2g of hydroxylamine chloride into a 35mL beaker filled with deionized water, stir magnetically at room temperature to disperse, and stir for 20min to obtain a mixed dispersion;

[0033] Step 2: Transfer the obtained mixed dispersion to a 50mL hydrothermal reaction kettle, put it in a constant temperature oven at 120°C for 14 hours, then let the reaction kettle cool down to room temperature naturally, and centrifuge at 11000-13000 rpm for 1 -3min, wash with deionized water and ethanol three times each, and dry in a constant temperature oven at 60°C to obtain a rod-shaped supramolecular intermediate;

[0034] Step 3: Weigh four portions of 1.2g supramolecular intermediates and place them in four crucibles (all four crucibles are covered), place the fou...

Embodiment 3

[0035] Embodiment 3: the preparation method of the supramolecular pre-assembled carbon nitrogen nanotube photocatalyst of the present invention, specifically comprises the following steps:

[0036] Step 1: Put 0.5g of melamine and 1.2g of hydroxylamine chloride into a 50mL beaker filled with deionized water, stir magnetically at room temperature to disperse, and stir for 25min to obtain a mixed dispersion;

[0037] Step 2: Transfer the obtained mixture to a 50mL hydrothermal reaction kettle, put it in a constant temperature oven at 150°C for 10 hours, then let the reaction kettle cool down to room temperature naturally, and centrifuge at 11000-13000 rpm for 1- 3min, washed with deionized water and ethanol three times each, and dried in a constant temperature oven at 60°C to obtain a rod-shaped supramolecular intermediate;

[0038] Step 3: Weigh four parts of 2g supramolecular intermediates respectively and place them in four crucibles (all four crucibles are covered). Control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com