Preparation method for polyether ether ketone

A polyether ether ketone and methoxy technology, which is applied in the field of preparation of heat-resistant polymer materials, can solve the problems of high freezing point, polyether ether ketone contains impurities, etc., and achieves lower synthesis temperature, easy processing, and convenient subsequent processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

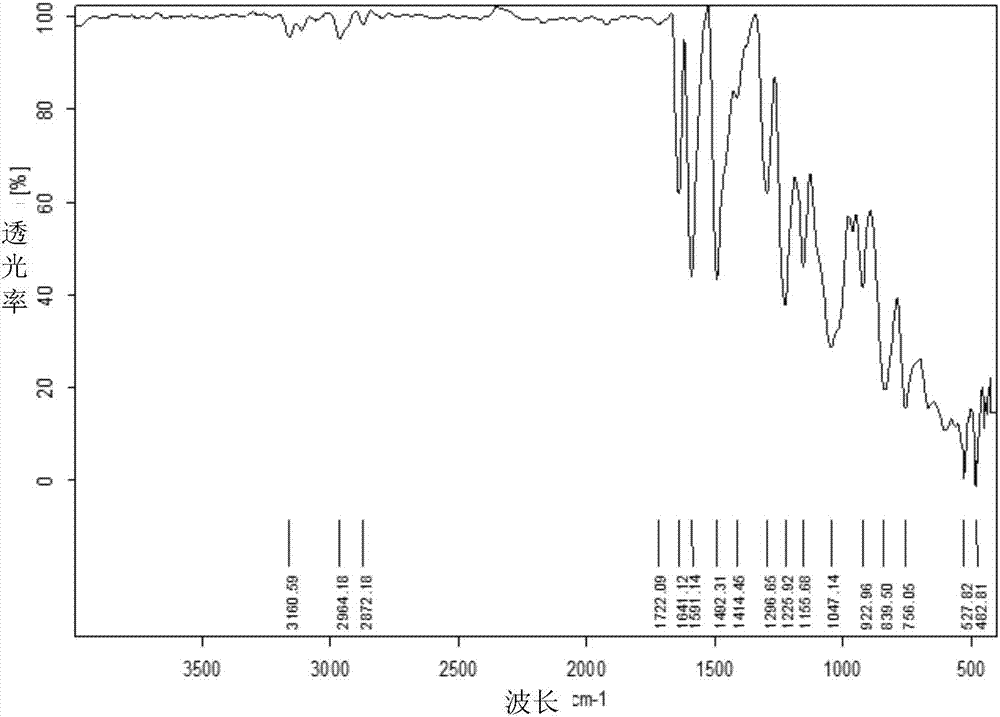

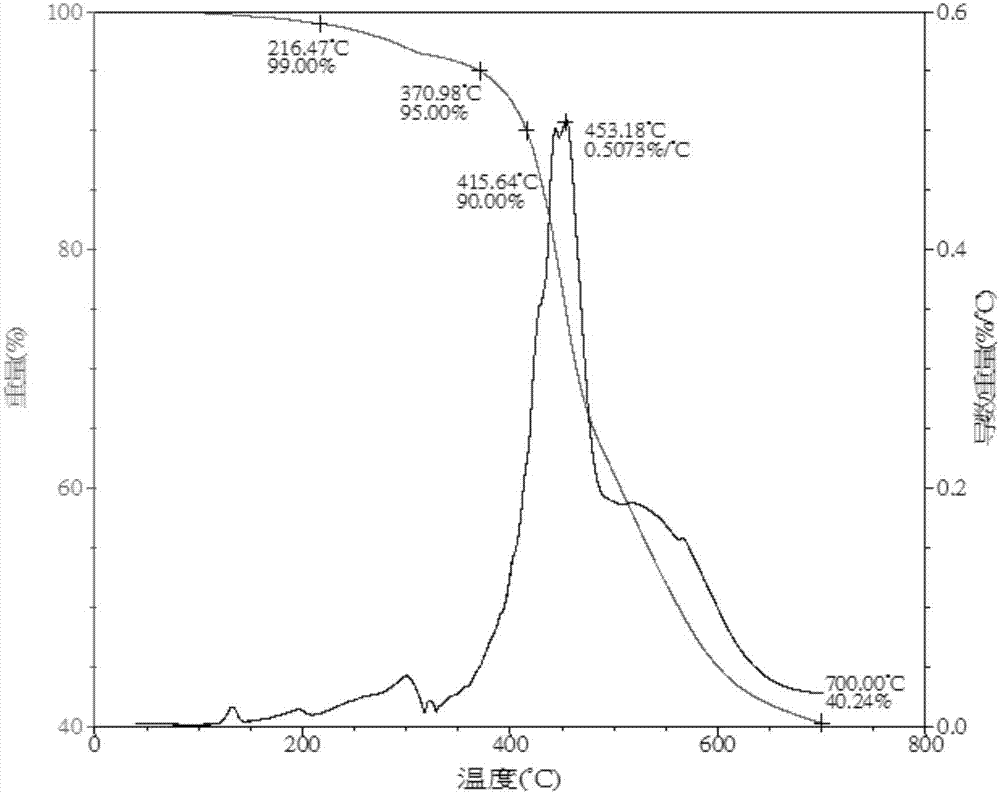

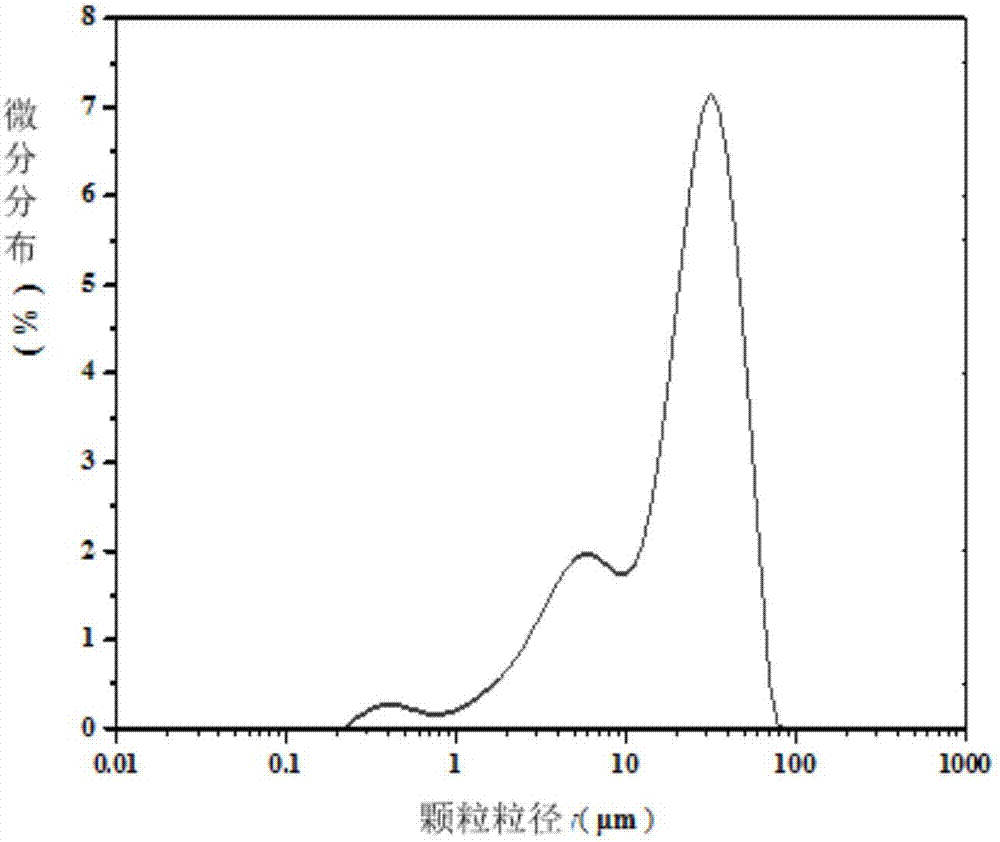

[0033] Under the protection of nitrogen, 10.90g of 4,4'-difluorobenzophenone was added to the solvent of 218.00g of 1-butyl-3-methylimidazolium bromide to obtain 4,4'-difluorobenzophenone solution, wherein the structure of 1-butyl-3-methylimidazolium bromide is shown as Heat the 4,4'-difluorobenzophenone solution to 40°C while stirring the 4,4'-difluorobenzophenone solution to fully dissolve the 4,4'-difluorobenzophenone, then cool to Standby at room temperature; under the protection of nitrogen, 5.50g of 1,4-benzenediol, 0.69g of anhydrous potassium carbonate and 4.77g of anhydrous sodium carbonate were uniformly mixed and divided into four equal parts, and 4,4'-bis In the fluorobenzophenone solution, keep stirring at a high speed (stirring speed can be 100-500 rpm), the interval between two adjacent additions is 30 minutes, the temperature is raised from normal temperature to 140 ° C, and the heating rate is 5 ° C / min, Insulate for 2 hours to fully dissolve 4,4'-difluoro...

Embodiment 2

[0040] Under argon protection, 21.80 g of 3,3'-difluorobenzophenone was added to a solvent of 218.00 g of 1,3-bis(2-methoxy-2-oxoethyl)imidazole chloride to give 44 '-difluorobenzophenone solution, wherein the structure of chlorinated 13-bis(2-methoxy-2-oxyethyl)imidazole is shown as: Heat the 4,4'-difluorobenzophenone solution to 25°C while stirring the 4,4'-difluorobenzophenone solution to fully dissolve the 4,4'-difluorobenzophenone, then cool to Standby at room temperature; under the protection of argon, 22.83g of bisphenol A, 1.38g of anhydrous potassium carbonate and 9.64g of anhydrous sodium carbonate were uniformly mixed and divided into four equal parts, and 3,3'-difluorodi In the benzophenone solution, keep stirring at a high speed (the stirring speed can be 100-500 rpm), the interval between two adjacent additions is 20 minutes, the temperature is raised from room temperature to 120 ° C, the heating rate is 10 ° C / min, and the temperature is kept for 1 h , fully...

Embodiment 3

[0044] Under the protection of argon, add 10.90g of 4,4'-difluorobenzophenone into the solvent of 327.00g of 1,3-bis(2-methoxy-2-oxyethyl)imidazole hexafluorophosphate, Obtain 4,4'-difluorobenzophenone solution, wherein, the structure of 1,3-bis(2-methoxy-2-oxyethyl)imidazole hexafluorophosphate is shown as: Warm up the 4,4'-difluorobenzophenone solution to 60°C while stirring the 4,4'-difluorobenzophenone solution to fully dissolve it, then cool it to room temperature for later use; under the protection of argon, put 16.02g of 2,6-dihydroxynaphthalene, 0.35g of anhydrous potassium carbonate and 4.39g of anhydrous sodium carbonate were evenly mixed and divided into five equal parts, and added to the 4,4'-difluorobenzophenone solution respectively, Continuous high-speed stirring (stirring speed can be 100-500 rpm), the interval between two adjacent additions is 40min, the temperature is raised from room temperature to 120°C, the heating rate is 20°C / min, and the heat preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com