Wear-resistant polyurethane material for wheels for forklift trucks

A polyurethane material and wheel technology, applied in the field of polyurethane, can solve the problems of insufficient wear resistance, easy safety accidents, poor dimensional stability, etc., and achieve excellent load-bearing capacity and service life, good durability, and improved wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

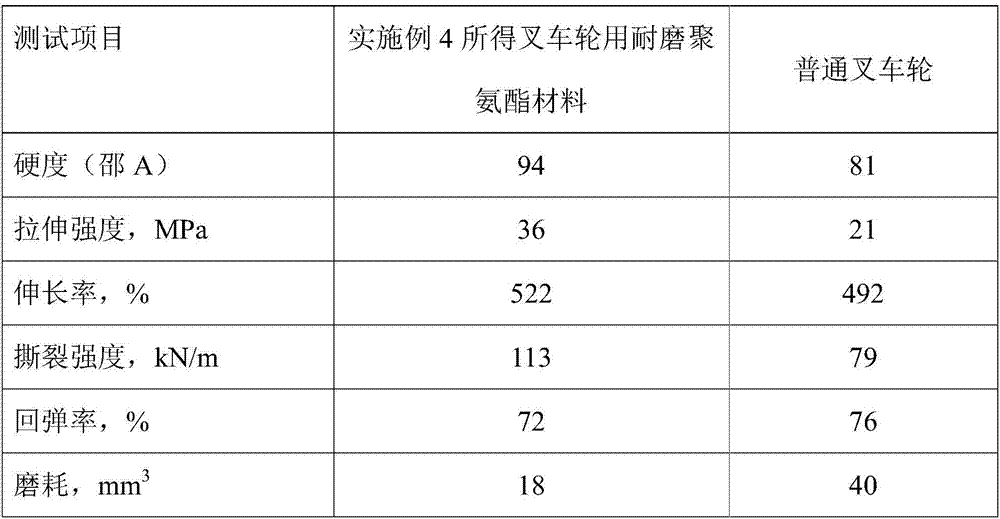

Examples

Embodiment 1

[0014] A wear-resistant polyurethane material for fork wheels, the raw materials of which include: 80g of polyoxypropylene diol, 20g of 1,6-hexamethylene diisocyanate trimer, 6g of trimethylolpropane, 8g of pentaerythritol, 7g of polypropylene compound, catalyst 4g, trimethylpentanediol 4g, talcum powder 13g, glass fiber 10g, diatomaceous earth 8g, surfactant 2g, sulfur accelerator 4g, sodium bicarbonate 4g, mold release agent 8g, toner 2g.

[0015] The catalyst includes: 2g of dibutyltin dilaurate and 0.4g of bismuth laurate. The release agent includes: oxidized polyethylene wax 2g, methyl silicone oil 2g.

[0016] The polypropylene composite was prepared by the following process: mix 10g of tapioca starch and 50g of phosphate buffer with a pH value of 5.2-5.8 evenly, add 0.04g of pullulanase for enzymolysis for 14 hours, inactivate the enzyme, add 10g of egg yolk lecithin, 16g of polysaccharide Propylene, 4g of 1,2-ethanedithiol, and 0.4g of benzophenone were mixed uniforml...

Embodiment 2

[0018] A wear-resistant polyurethane material for fork wheels, the raw materials of which include: 100g of polyoxypropylene diol, 10g of 1,6-hexamethylene diisocyanate trimer, 10g of trimethylolpropane, 4g of pentaerythritol, 12g of polypropylene compound, catalyst 2g, trimethylpentanediol 8g, talcum powder 7g, glass fiber 20g, diatomaceous earth 4g, surfactant 4g, sulfur accelerator 2g, sodium bicarbonate 6g, mold release agent 4g, toner 4g.

[0019] The catalyst includes: 1 g of dibutyltin dilaurate and 0.7 g of bismuth laurate. The release agent includes: oxidized polyethylene wax 1g, methyl silicone oil 4g.

[0020] The polypropylene composite was prepared by the following process: mix 6g of tapioca starch and 70g of phosphate buffer with a pH value of 5.2-5.8 evenly, add 0.02g of pullulanase for enzymolysis for 20h, inactivate the enzyme, add 6g of egg yolk lecithin, 20g of polymer Propylene, 2g of 1,2-ethanedithiol, and 0.8g of benzophenone were mixed uniformly, treated...

Embodiment 3

[0022] A wear-resistant polyurethane material for fork wheels, the raw materials of which include: 85g of polyoxypropylene diol, 18g of 1,6-hexamethylene diisocyanate trimer, 7g of trimethylolpropane, 7g of pentaerythritol, 8g of polypropylene compound, catalyst 3.5g, trimethylpentanediol 5g, talcum powder 12g, glass fiber 12g, diatomaceous earth 7g, surfactant 2.5g, sulfur accelerator 3.5g, sodium bicarbonate 5g, release agent 7g, toner 2.5g .

[0023] The catalyst includes: 1.7 g of dibutyltin dilaurate and 0.5 g of bismuth laurate. The release agent includes: oxidized polyethylene wax 1.8g, methyl silicone oil 2.5g.

[0024] The polypropylene composite was prepared by the following process: mix 9g of tapioca starch and 55g of phosphate buffer with a pH value of 5.2-5.8 evenly, add 0.035g of pullulanase for enzymolysis for 16 hours, inactivate the enzyme, add 9g of egg yolk lecithin, 17g of polymer Propylene, 3.5g of 1,2-ethanedithiol, and 0.5g of benzophenone were mixed u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com