Hydroxyl terminated polyester resin for powder paint, preparation method and prepared powder paint

A hydroxyl-terminated polyester and powder coating technology, applied in the polymer field, can solve the problems of poor mechanical properties, poor dispersion of titanium dioxide, and high dosage, and achieve the effects of reducing the amount of addition, superior mechanical properties, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The titanium dioxide is rutile titanium dioxide or anatase titanium dioxide. Prepare the preparation method of hydroxyl-terminated polyester resin for powder coating as above, it comprises the following steps:

[0030] (1) Add the described polyhydric alcohol and branching agent of proportioning amount in reactor, heat up, then add described aromatic polyacid, fatty polyacid, inorganic pigment and catalyst of proportioning amount successively, pass into nitrogen and continue to heat up At 250°C, react for 5-12 hours until 95% of the esterified water is discharged, and the acid value reaches 8-20 mgKOH / g;

[0031] (2) Add the acidolysis agent of polyester ratio in the reaction kettle, react for 1-7 hours, until the acid value reaches 27-70mgKOH / g, vacuum polycondensation, the polycondensation time is 0.5-2 hours, make its viscosity reach 2500-6500mPa·s, and then perform a capping reaction for 0.5-3 hours to obtain the hydroxyl-terminated polyester resin with a molecular...

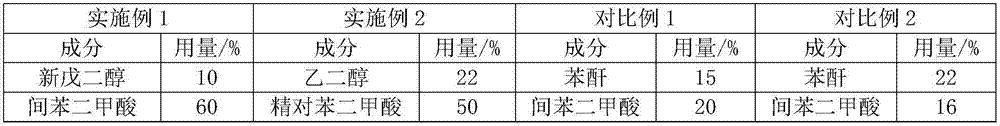

Embodiment 1

[0033] The hydroxyl-terminated polyester resin includes the following components, each component is by weight percentage: neopentyl glycol 10%, isophthalic acid 60%, adipic acid 1%, trimethylolpropane 1.5%, 1.4- Cyclohexanedicarboxylic acid 27.2%, monobutyltin oxide 0.1%, titanium dioxide 0.2%.

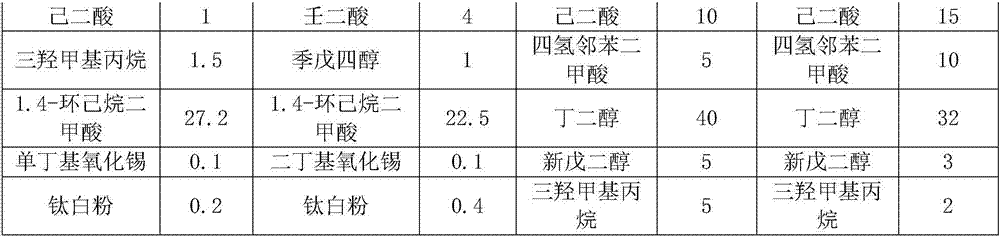

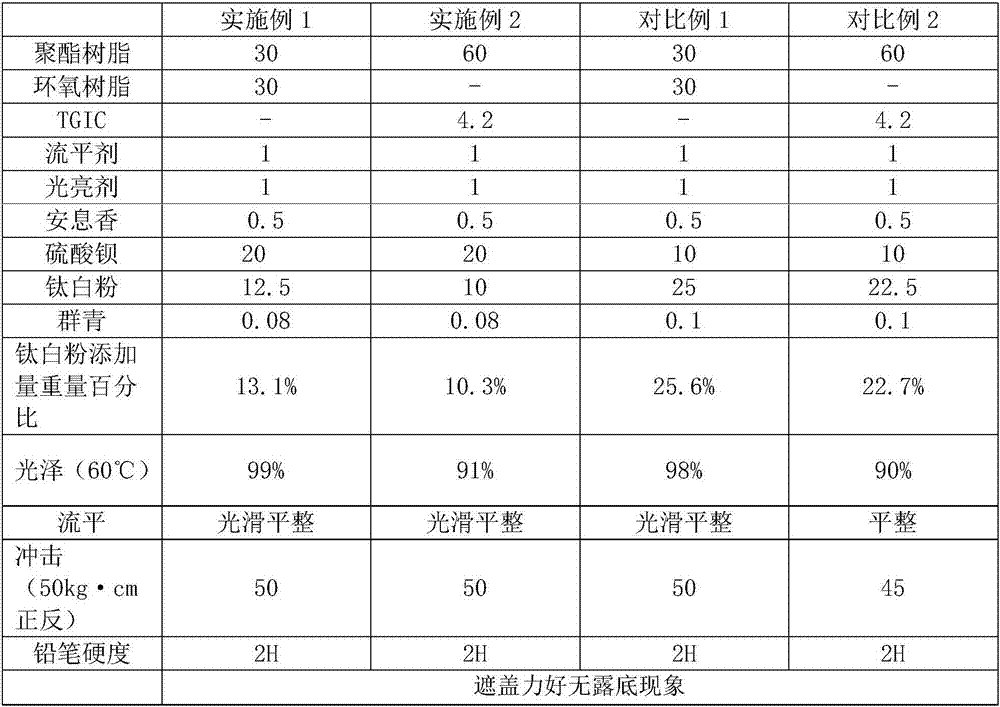

[0034] The hydroxyl-terminated polyester resin prepared according to the above steps and components is used to prepare powder coatings. The powder coatings are white and suitable for indoor use. The composition of the powder coatings includes: the 30kg of hydroxyl-terminated polyester resin; epoxy resin at 0.12mol / 100g epoxy resin 30kg; leveling agent 1kg, brightener 1kg, benzoin 0.5kg; barium sulfate 20kg, the barium sulfate is preferably precipitated barium or ultrafine barium ; Titanium dioxide 12.5kg, said titanium dioxide is preferably rutile titanium dioxide; Ultramarine 0.08kg.

Embodiment 2

[0036] The hydroxyl-terminated polyester resin includes the following components, each component is by weight percentage: 22% neopentyl glycol, 50% isophthalic acid, 4% adipic acid, 1% trimethylolpropane, 1.4- Cyclohexanedicarboxylic acid 22.5%, monobutyltin oxide 0.1%, titanium dioxide 0.4%.

[0037] The hydroxyl-terminated polyester resin prepared according to the above steps is used to prepare a powder coating. The powder coating is white and suitable for outdoor use. Its composition includes: 30 kg of the hydroxyl-terminated polyester resin with an acid value of about 32 mgKOH / g; TGIC curing agent 4.2kg; Leveling agent 1kg, brightener 1kg, benzoin 0.5kg; Barium sulfate 20kg, described barium sulfate is preferably precipitated barium or ultrafine barium; Titanium dioxide 12.5kg, described titanium dioxide is preferably rutile type titanium white powder; ultramarine 0.08kg.

[0038] The formula of hydroxyl-terminated polyester resin prepared by the present invention and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com