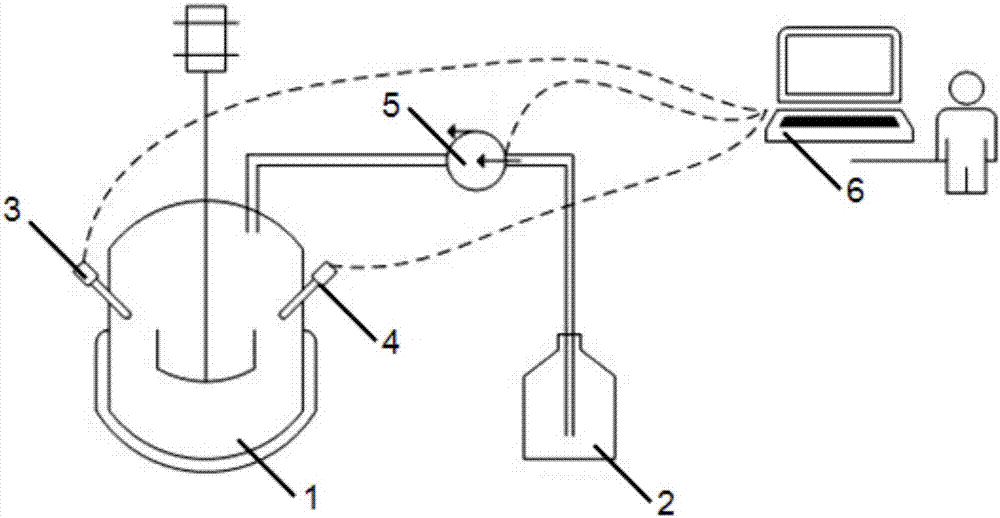

Fermentation feeding optimizing control system and method thereof

An optimization control and feeding technology, applied in the field of fermentation feeding optimization control system, can solve the problems of increased probability of contamination, long time, and high requirements for manual operation, and achieves the improvement of protein expression, the reduction of pollution probability, and the simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

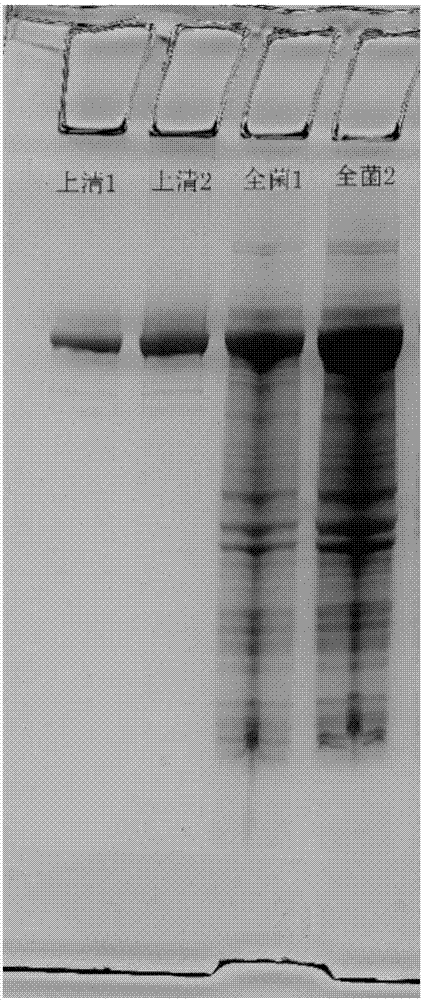

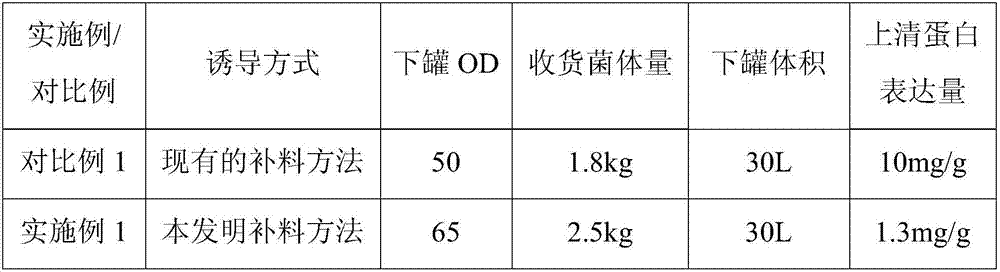

Embodiment 1

[0033] Take the fermentation of 30L rosseta strain as an example.

[0034] (1) Primary medium: sodium chloride 10g / L, tryptone 10g / L, yeast extract powder 5g / L.

[0035] (2) Secondary medium: tryptone 12g / L, yeast extract powder 24g / L, dipotassium hydrogen phosphate trihydrate 16.45g / L, potassium dihydrogen phosphate 2.31g / L, glycerin 5g / L.

[0036] (3) The fermentation medium includes: 48mmol / L disodium hydrogen phosphate, 20mmol / L sodium dihydrogen phosphate, 16mmol / L ammonium citrate, 9mmol / L magnesium sulfate heptahydrate, 24g / L glucose and 1.9g / L Yeast extract powder, 3.8g / L tryptone, 0.1% trace elements, 0.09% defoamer, pH 7.2. Among them, magnesium sulfate heptahydrate, glucose and trace elements are sterilized separately.

[0037](4) Feed medium includes: 80mmol / L magnesium sulfate heptahydrate, 640g / L glucose and 38.8g / L yeast extract powder and 19.4g / L tryptone, 0.15% trace elements and 0.09% defoamer . Yeast extract powder, tryptone and antifoaming agent are ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com