Preparation method for nano spherical carbon aerogel

A carbon airgel and aerogel technology are applied in the preparation/purification of carbon, the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., which can solve the problems of human body hazards and high production costs, and achieve low cost, The effect of fast reaction speed and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

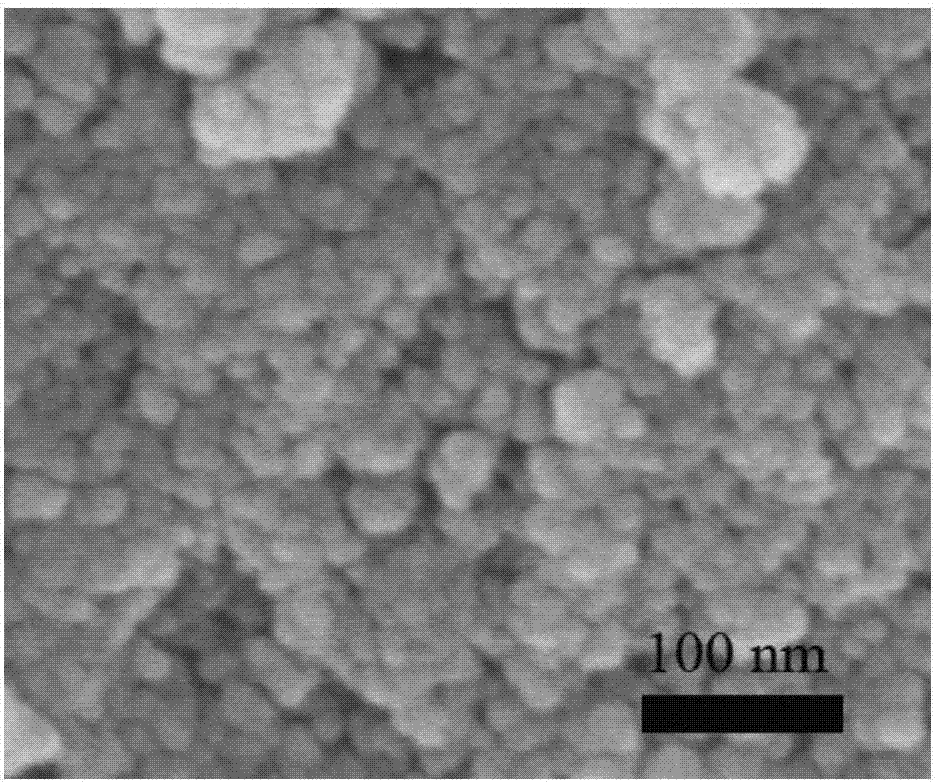

Image

Examples

Embodiment 1

[0036] (1) Ammonia solution with a pH value of 10 is mixed with alginic acid to form a mixed solution, wherein alginic acid accounts for 5% of the total mass of the mixed solution, and then the mixed solution is added to the acetone under stirring at a volume ratio of 1:25, And keep stirring for 4 hours, centrifuge and dry under normal pressure at 80°C to obtain nano-spherical alginic acid-based carbon airgel;

[0037] (2) Place the nano-spherical alginic acid-based carbon aerogel in a tube furnace, and under the protection of nitrogen, heat up to 700 °C at a rate of 3 °C / min, keep it warm for 3 hours, and then cool to room temperature to obtain carbonized nano-spherical Alginate-based carbon airgel;

[0038] (3) Mix the carbonized nano-spherical alginate-based carbon aerogel with KOH at a mass ratio of 1:4, put it back in the tube furnace, and raise the temperature to 800 °C at a rate of 4 °C / min under the protection of nitrogen. Insulated for 2 hours, then cooled to room te...

Embodiment 2

[0041] (1) Mix ethylenediamine solution with a pH value of 9 and alginic acid to form a mixed solution, wherein alginic acid accounts for 10% of the total mass of the mixed solution, and then add the mixed solution to ethanol under stirring at a volume ratio of 1:70 , and continuously stirred for 6 hours, centrifuged and dried under normal pressure at 80°C to obtain nano-spherical alginic acid-based carbon airgel;

[0042] (2) Place the nano-spherical alginic acid-based carbon aerogel in a tube furnace, and under the protection of nitrogen, heat up to 850 °C at a rate of 4 °C / min, keep it warm for 4 hours, and then cool to room temperature to obtain carbonized nano-spherical Alginate-based carbon airgel;

[0043] (3) Mix the carbonized nano-spherical alginate-based carbon aerogel with KOH at a mass ratio of 1:3, put it back in the tube furnace, and raise the temperature to 920 °C at a rate of 3 °C / min under the protection of nitrogen. Insulated for 3 hours, and then cooled to...

Embodiment 3

[0046] (1) Mix ethylenediamine solution with a pH value of 8 and alginic acid to form a mixed solution, wherein alginic acid accounts for 7% of the total mass of the mixed solution, and then add the mixed solution to ethanol under stirring at a volume ratio of 1:45 , and continuously stirred for 7 hours, centrifuged and dried under normal pressure at 80°C to obtain nano-spherical alginic acid-based carbon airgel;

[0047] (2) Place the nano-spherical alginic acid-based carbon airgel in a tube furnace, and under the protection of nitrogen, heat up to 640 °C at a rate of 3 °C / min, keep it warm for 4 hours, and then cool to room temperature to obtain carbonized nano-spherical Alginate-based carbon aerogel;

[0048] (3) Mix the carbonized nano-spherical alginate-based carbon airgel with KOH at a mass ratio of 1:5, put it back in the tube furnace, and raise the temperature to 750 °C at a rate of 4 °C / min under the protection of nitrogen. Insulated for 2 hours, then cooled to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com