Preparation of nano-lanthanum hydroxide composite material and method for removing trace phosphorus in waste water

A technology of lanthanum hydroxide and composite materials, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of low utilization rate of high-activity nanometer lanthanum hydroxide, pore blockage, and low phosphate mass transfer rate. and other problems, to achieve the effect of excellent adsorption selection performance, promotion of dispersion and activity, and obvious environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

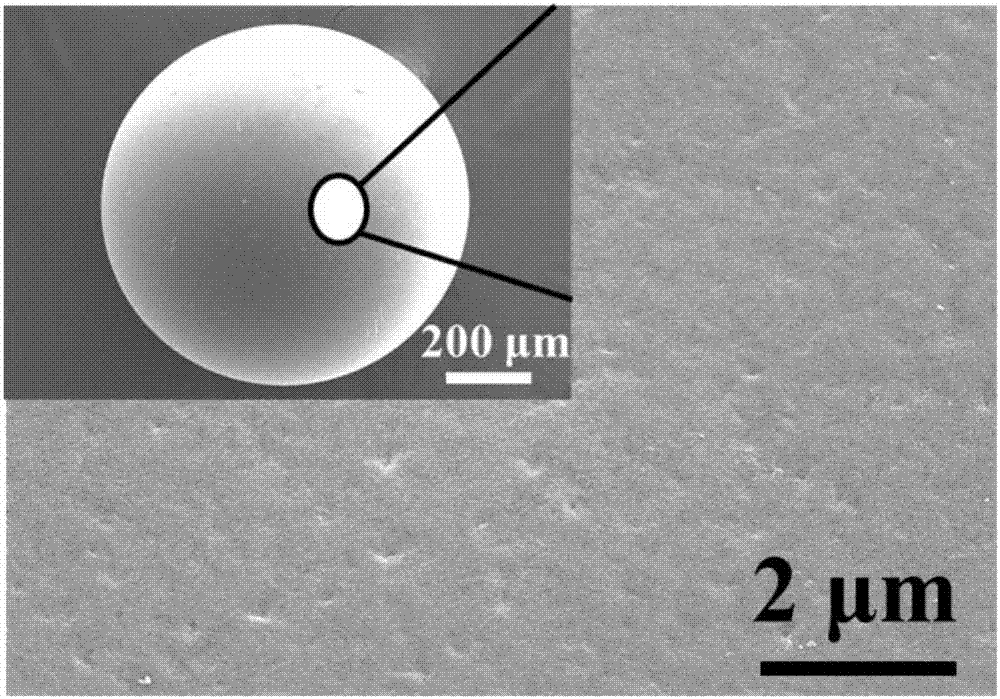

Embodiment 1

[0026] Measure 50mL of D201 resin (produced by Hangzhou Zhengguang Industrial Co., Ltd., the same below) as the initial reaction substance, first place it in a Tris-HCl buffer solution with a mass fraction of 1g / L and a pH of 7.5, and control the temperature at 20 ℃, after 12 hours of aeration reaction, filter to obtain the macroporous polymeric sphere mother plate material coated with polydopamine, use 20mL of the polymeric sphere as a carrier, place it in 40mL containing 1% La(III) (calculated as lanthanum mass fraction , lanthanum nitrate as the precursor) in an aqueous solution at 50°C for 6 hours to fully diffuse the lanthanum salt to the inner surface of the polymerization sphere, filter, then place 40 mL of ammonia water with a mass fraction of 1%, fully stir the reaction at 50°C for 12 hours, and filter , the above materials were fixed in a vacuum oven at 60° C. for 4 hours to obtain the target resin-based polydopamine nano-lanthanum hydroxide composite material, and th...

Embodiment 2

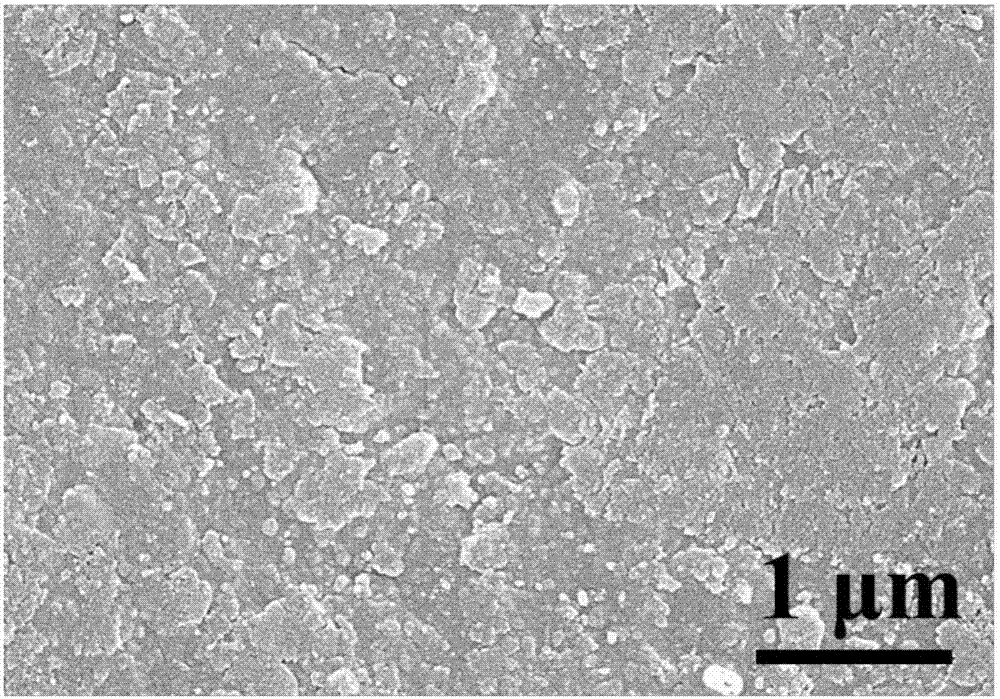

[0035] Take 50mL of D201 resin (produced by Hangzhou Zhengguang Industrial Co., Ltd., the same below) as the initial reaction substance, first place it in a Tris-HCl buffer solution with a mass fraction of 2.2g / L and a pH of 8.5, and control the temperature at 30°C, aerated for 24 hours and then filtered to obtain a macroporous polymeric sphere mother plate material coated with polydopamine. With 30mL of the polymeric sphere as a carrier, it was placed in 300mL containing 10% La(III) (calculated as the mass fraction of lanthanum) , lanthanum chloride as the precursor) in an aqueous solution at 60°C for 8 hours to fully diffuse the lanthanum salt to the inner surface of the polymeric sphere channel, filter, then dropwise add 150mL of ammonia water with a mass fraction of 4%, fully stir the reaction at 60°C for 24h, filter , the above materials were fixed in a vacuum oven at 80° C. for 8 hours to obtain the target resin-based polydopamine nano-lanthanum hydroxide composite materi...

Embodiment 3

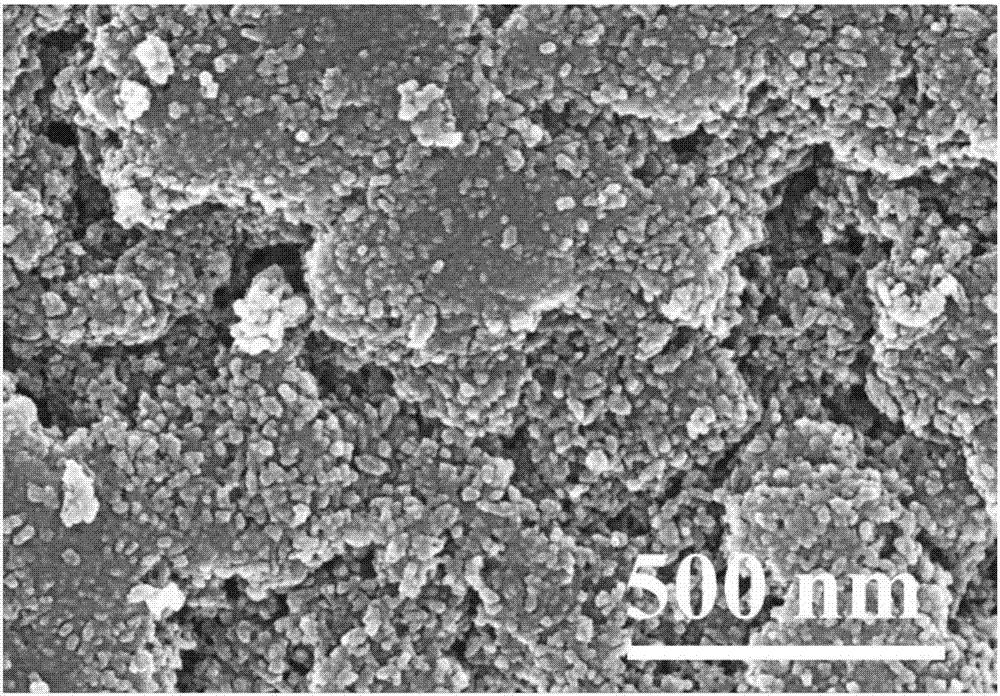

[0038] Measure 30mL of 201x7 resin (produced by Hangzhou Zhengguang Industrial Co., Ltd.) as the starting reaction substance, first place it in a Tris-HCl buffer solution with a mass fraction of 1.8g / L and a pH of 8.2, and control the temperature at 25°C. Aerated for 16 hours and then filtered to obtain a macroporous polymeric sphere mother plate material coated with polydopamine, with 20mL of the polymeric sphere as a carrier, it was placed in 100mL containing 3% La(III) (calculated as lanthanum mass fraction, lanthanum nitrate (precursor) in an aqueous solution at 50°C for 7 hours to fully diffuse the lanthanum salt to the inner surface of the polymeric sphere pores, filter, then dropwise add 85 mL of ammonia water with a mass fraction of 2%, fully stir the reaction at 55°C for 18 hours, filter, and dissolve the above materials Place in a vacuum oven at 70° C. for 6 hours to obtain the target resin-based polydopamine nano-lanthanum hydroxide composite material, with a loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com