Hydrothermal-resistant and sulfur-tolerant overall structure combustion catalyst and preparation method thereof

A technology of combustion catalyst and overall structure, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of good sulfur resistance, low manufacturing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

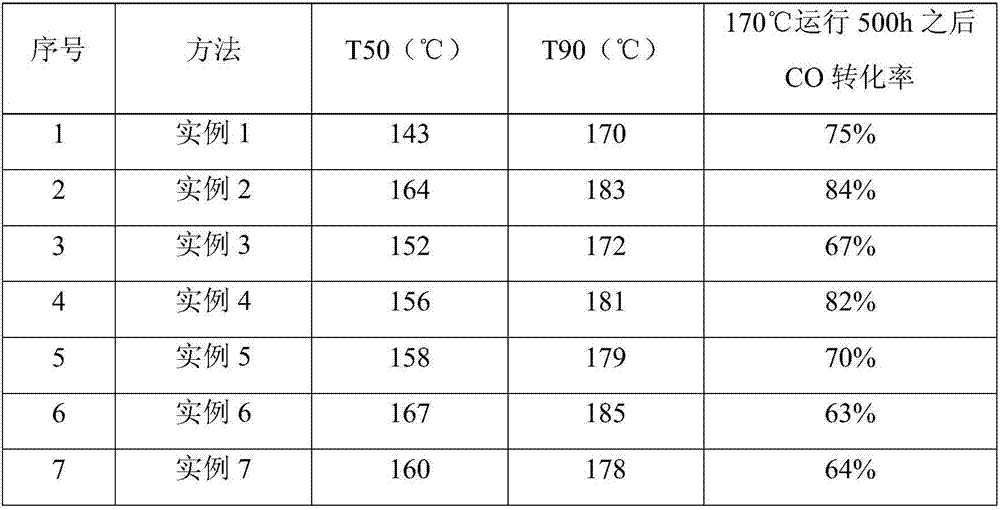

Examples

Embodiment 1

[0021] Weigh 5.85g of ammonium metavanadate and 2.84g of ammonium paratungstate into 100ml of deionized water, boil and dissolve to obtain solution A; then weigh 11.64g of cobalt nitrate hexahydrate and mix it in 200ml of deionized water to obtain solution B; , Solution B is added to the ball mill jar, and then 16gTiO 2 , 10g silica sol, 30g aluminum sol, the mixture was ball milled for 2 hours at a rotating speed of 500 rpm to obtain a coating slurry; the whole honeycomb carrier was immersed in the coating slurry, and the excess honeycomb carrier hole was blown out with compressed air. The coating solution; then the honeycomb carrier coated with the oxide coating was dried by microwave for 10 minutes, and then baked at 650 ° C for 3 hours to obtain a carrier coated with a mixed oxide coating; The carrier was immersed in palladium nitrate and chloroplatinic acid solutions in turn, and the excess solution in the pores of the honeycomb carrier was blown out with compressed air; ...

Embodiment 2

[0023] Weigh 17.55g of ammonium metavanadate and 8.52g of ammonium paratungstate and add them to 150ml of deionized water, boil and dissolve to make solution A; then weigh 16.16g of ferric nitrate nonahydrate and mix them in 200ml of deionized water to make solution B; , Solution B is added to the ball mill jar, and then 24gTiO 2 , 40g aluminum sol, the mixture was ball milled for 3 hours at a rotating speed of 500 rpm to obtain a coating slurry; the whole honeycomb carrier was immersed in the coating slurry, and the excess coating liquid in the pores of the honeycomb carrier was blown out with compressed air ; Then the honeycomb carrier coated with the oxide coating was dried by microwave for 8 minutes, and then baked at 550 ° C for 4 hours to obtain a carrier coated with a mixed oxide coating; the carrier coated with a mixed oxide coating was sequentially immersed in palladium nitrate and chloroplatinic acid solution, use compressed air to blow out excess solution in the por...

Embodiment 3

[0025] Weigh 17.55g of ammonium metavanadate and 7.1g of ammonium paratungstate and add them to 150ml of deionized water, boil and dissolve to make solution A; then weigh 8.73g of nickel nitrate hexahydrate and mix them in 200ml of deionized water to make solution B; , B solution is added to the ball mill jar, and then add 28gTiO 2, 40g of silica sol, the mixture was ball milled for 2 hours at a rotating speed of 500 rpm to obtain a coating slurry; the whole honeycomb carrier was immersed in the coating slurry, and the excess coating liquid in the pores of the honeycomb carrier was blown out with compressed air ; Then the honeycomb carrier coated with the oxide coating was dried by microwave for 10 minutes, and then baked at 650 ° C for 3 hours to obtain a carrier coated with a mixed oxide coating; the carrier coated with a mixed oxide coating was immersed once A mixed solution of palladium nitrate and chloroplatinic acid was used to blow out the excess solution in the pores o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com