A kind of rhodium/phosphorene supported catalyst and its preparation method and application

A supported catalyst, phosphorene technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as complex preparation process, achieve high catalytic activity, high hydrogenation degree, preparation Simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a phosphorene sheet.

[0031] Put 300mg of black phosphorus in 80ml of pyrrolidone solution (concentration: 3.75mg / L) and sonicate for 2h, dilute the above-mentioned phosphorene into 80ml of deionized water, and continue to sonicate in the ultrasonic machine for 30min to obtain a black suspension containing phosphorene sheets liquid.

[0032] The suspension liquid obtained in this example has a stable dispersion system and no precipitation upon standing. The Raman shifts of the in-plane and out-of-plane vibration modes of the sheet are changed.

[0033] The phosphorene sheet layer obtained in this embodiment has a thickness of 50 nm and an average number of layers of 20.

Embodiment 2

[0035] This example provides a method for preparing a rhodium / phosphorene supported catalyst.

[0036] Weigh 0.5mg RhCl 3 Dissolved in 10mL deionized water to prepare 5g / L, after RhCl 3 After fully dissolving, join in the phosphorene lamellar suspension prepared by 20g embodiment 1 (phosphorene and RhCl 3 mass ratio 2:1), heated in a water bath at 80°C for 4 hours, centrifuged, washed, and dried to obtain a rhodium / phosphorene supported catalyst. The rhodium / phosphorene supported catalyst obtained in this example is black powder.

[0037] The rhodium nanoparticles in the obtained catalyst had a particle diameter of 10 nm.

Embodiment 3

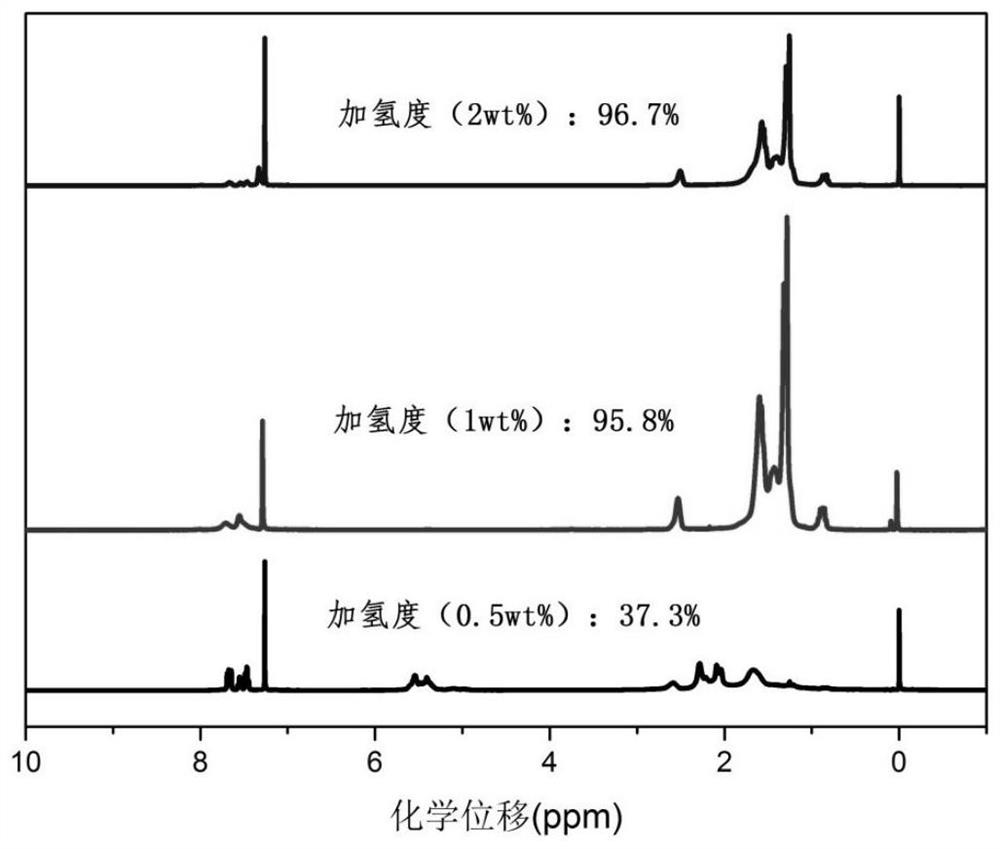

[0039] This embodiment provides a method for catalytic hydrogenation of rubber.

[0040] Dissolve NBR in chlorobenzene to prepare NBR glue with a mass fraction of 10%.

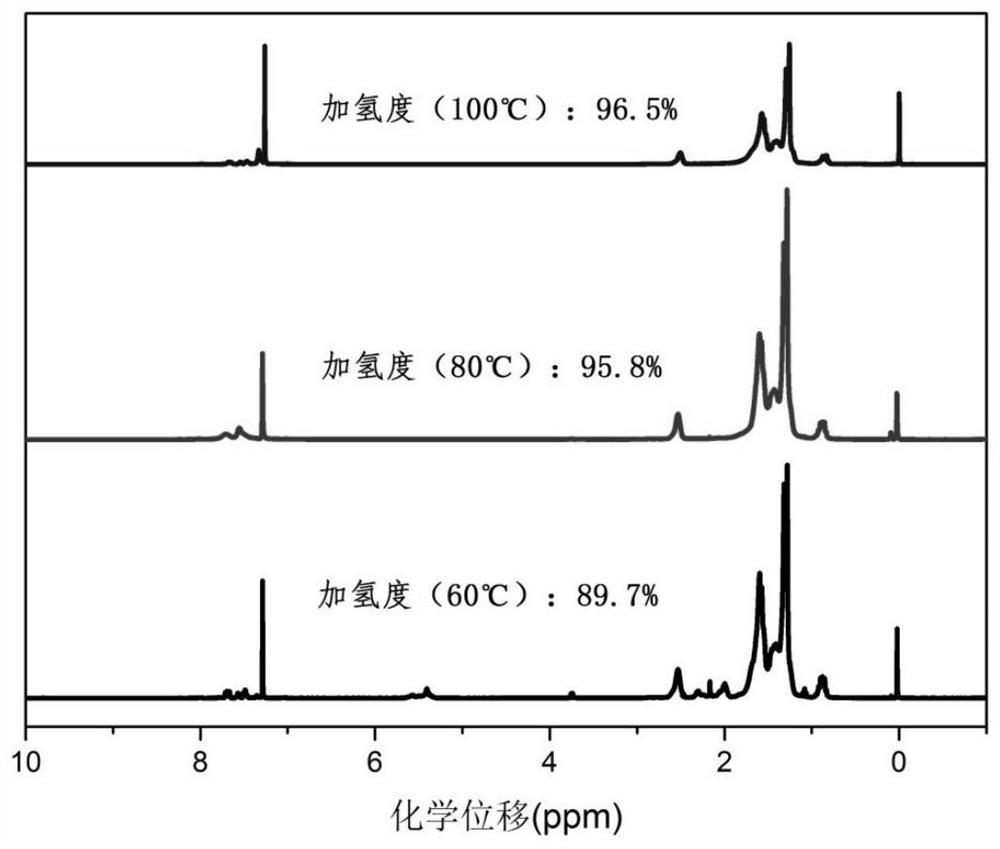

[0041] Get 5g of NBR glue solution and place in 30ml reactor, add the rhodium / phosphorene supported catalyst that the embodiment 2 of glue solution mass fraction 1% makes, under the condition of pressure 4MPa, rotating speed 400r / min, at temperature 60 ℃, 80 respectively ℃, 100 ℃ hydrogenation reaction for 8 hours. The hydrogenation degree results are shown in Table 1 below, and the nuclear magnetic spectrum after hydrogenation is as follows figure 1 shown.

[0042] Table 1 Degree of hydrogenation at different temperatures

[0043] serial number temperature / ℃ Hydrogenation degree / % 1 60 89.7 2 80 95.8 3 100 96.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com