Method for improving biodegradability through heterogeneous Fenton oxidation treatment of cotton pulp black liquor

A Fenton oxidation and biochemical technology, applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of application limitation, low utilization rate, large amount of sludge, etc. cost, improve biodegradability, and solve the effect of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

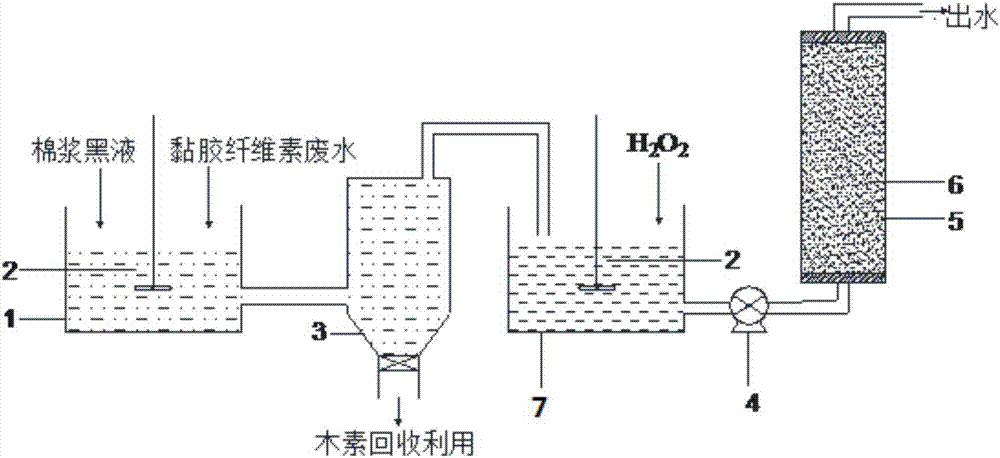

Image

Examples

Embodiment 1

[0028] The pH value of cotton pulp black liquor from a company in Xinjiang is 10.5-11.5, SS is 512-654mg / L, COD Cr 20460mg / L, BOD 5 It is 7550mg / L, and the chroma is 1820 times. The cotton pulp black liquor and the deacidified water (pH=1.5) discharged from the viscose fiber production of the company are mixed in the first stirring reaction tank 1 at a volume ratio of 1:4.2, and adjusted The pH of the mixed wastewater is 3.5, the effluent enters the solid-liquid separation device 3 acid analysis method for 1 hour, filter and separate, collect the precipitated lignin for recycling, and the supernatant COD Cr 14800mg / L, BOD 5 It is 5020mg / L, and the chromaticity is 950 times, and the effluent enters the second stirring reaction tank 7 and H 2 o 2 The solution was mixed, and H was added 2 o 2 Industrial hydrogen peroxide with a mass concentration of 27%, H 2 o 2 The amount of solution added is 5ml / L, and the waste water and H 2 o 2 The mixed solution is transported under...

Embodiment 2

[0030] The pH value of cotton pulp black liquor from a Jiangsu company is 10.8-11.5, SS is 505-582mg / L, COD Cr 18860mg / L, BOD 5 It is 5700mg / L, and the chroma is 1700 times. The cotton pulp black liquor is mixed with the second bath water (pH=1.8) discharged from the company's viscose fiber production at a volume ratio of 1:4.2 and placed in the first stirring reaction tank 1. The pH of the mixed wastewater is 3.5, the effluent enters the solid-liquid separation device 3 acid analysis method for 1 hour, filter and separate, collect the precipitated lignin for recycling, and the supernatant COD Cr11900mg / L, BOD 5 It is 4593mg / L, and the chromaticity is 970 times, and the effluent enters the second stirring reaction tank 7 and H 2 o 2 The solution was mixed, and H was added 2 o 2 Industrial hydrogen peroxide with a mass concentration of 27%, H 2 o 2 The amount of solution added is 5ml / L, and the waste water and H 2 o 2 The mixed solution is transported under pressure by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com