Heat insulating coating for building external wall and preparation method thereof

A technology for thermal insulation and building exterior walls, applied in the direction of reflection/signal paint, coating, etc., can solve the problem of immaturity and other problems, and achieve the effect of eliminating condensation, improving thermal insulation effect, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

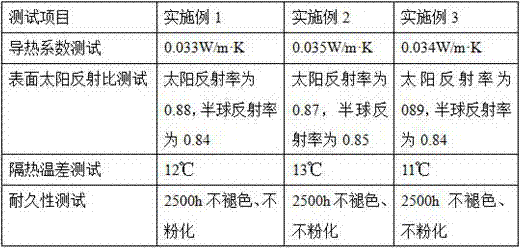

Examples

Embodiment 1

[0040] First, 40 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 1 part of N-methylol acrylamide, 6 parts of fumed silica, 4 parts of water, 1 part of titanate coupling agent (monoalkoxypyrophosphate titanate coupling agent), 7 parts of auxiliary agent (1 part of dithiocarbamate , 1 part cellulose acetate butyrate, 1 part hydroxyethyl cellulose, 4 parts 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate), 7 parts n-butyl acetate, 9 parts of heat insulation materials (a mixture of hollow glass microspheres, expanded perlite and aluminum silicate fibers, the proportion of the three parts by weight is 1:1:1, among which, the hollow glass microspheres are obtained from the research of Sinosteel Ma'anshan Mine Institute Co., Ltd. architectural coatings adapt to model T32), 5 parts of modified nano-calcium carbonate, for material preparation.

[0041] The preparation method of the modified ...

Embodiment 2

[0047]First, 45 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 1.5 parts of N-methylol acrylamide, 7 parts of fumed silica, 5 parts of water, 1.5 parts of titanate coupling agent (monoalkoxypyrophosphate titanate coupling agent), 12 parts of additives (1.5 parts of pentachlorophenol, 2 parts of acetic acid Cellulose butyrate, 2 parts hydroxyethylcellulose, 5 parts 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate), 8 parts n-butyl acetate, 10 parts thermal insulation Insulation material (a mixture of hollow glass microspheres, expanded perlite and aluminum silicate fibers, the proportion of the three parts by weight is 1:1:1, among which, the hollow glass microspheres are constructed by Sinosteel Maanshan Mining Research Institute Co., Ltd. The paint is adapted to the model T40), and 8 parts of modified nano-calcium carbonate are used for material preparation.

[0048] The preparati...

Embodiment 3

[0054] First, 50 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 2 parts of N-methylol acrylamide, 9 parts of fumed silica, 6 parts of water, 2 parts of titanate coupling agent (monoalkoxy pyrophosphate type titanate coupling agent), 14 parts of auxiliary agent (2 parts of dithiocarbamate , 3 parts cellulose acetate butyrate, 3 parts hydroxyethyl cellulose, 6 parts 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate), 9 parts n-butyl acetate, 12 parts of thermal insulation materials (a mixture of hollow glass microspheres, expanded perlite and aluminum silicate fibers, the ratio of the three parts by weight is 1:1:1, among which, the hollow glass microspheres are obtained from the Maanshan Mine of Sinosteel Group. Institute Co., Ltd. architectural coatings adapt to model T46), 10 parts of modified nano-calcium carbonate, for material preparation.

[0055] The preparation method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com