Chitosan-coating sweet-scented osmanthus phenylethanoid glycosides lipidosome and preparation method of chitosan-coating sweet-scented osmanthus phenylethanoid glycosides lipidosome

A technology of osmanthus phenylethanol glycoside and phenylethanol glycoside, which is applied in the field of chitosan-coated osmanthus phenylethanol glycoside liposome and its preparation, can solve the problem of unstable liposome structure, large particle size, and core material Leakage and other problems can be achieved to increase the slow-release effect, improve stability, and prevent aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

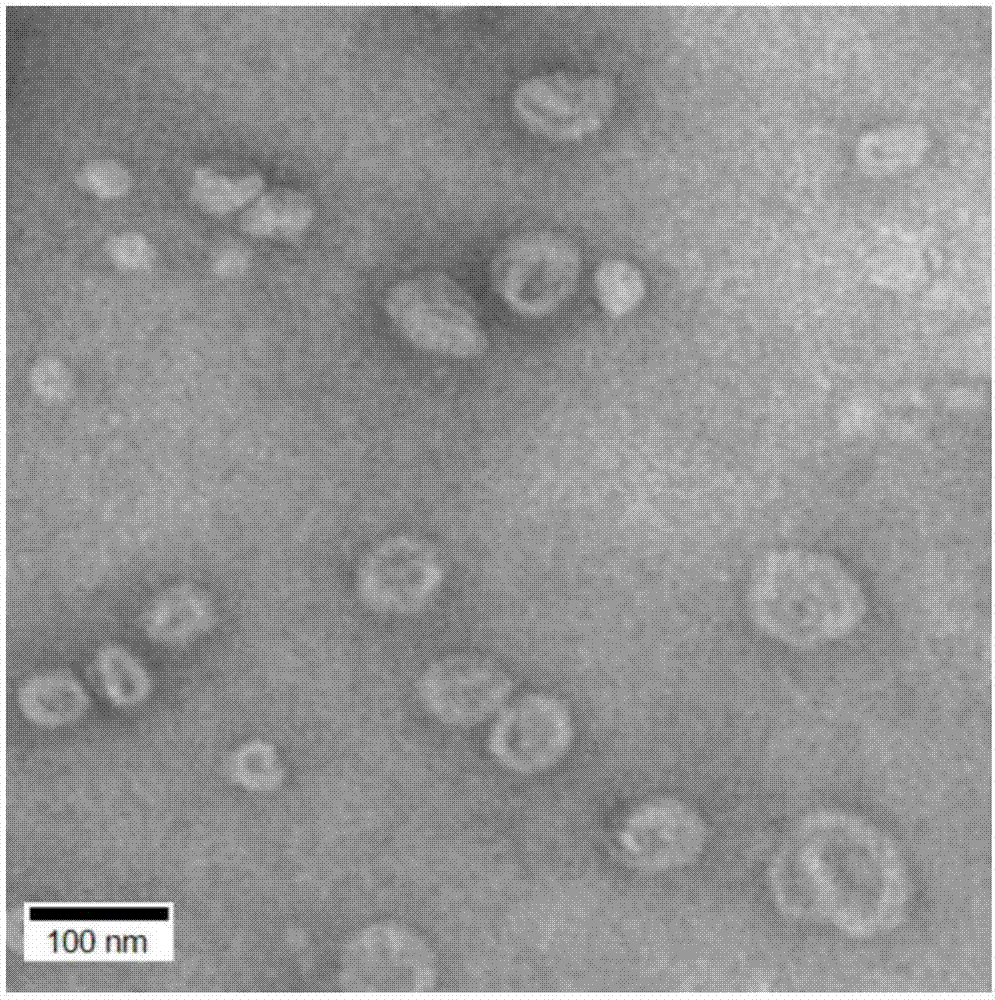

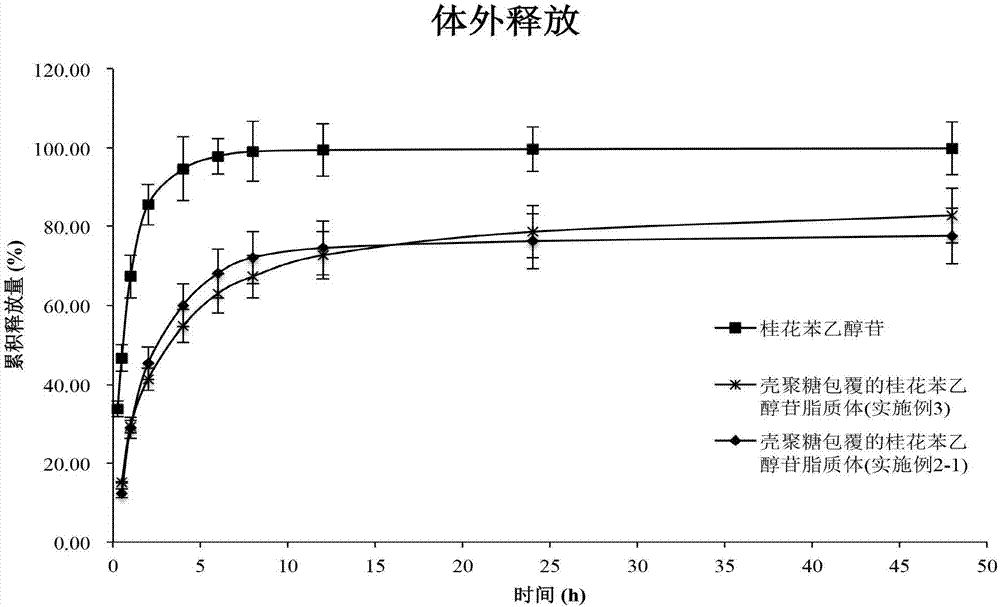

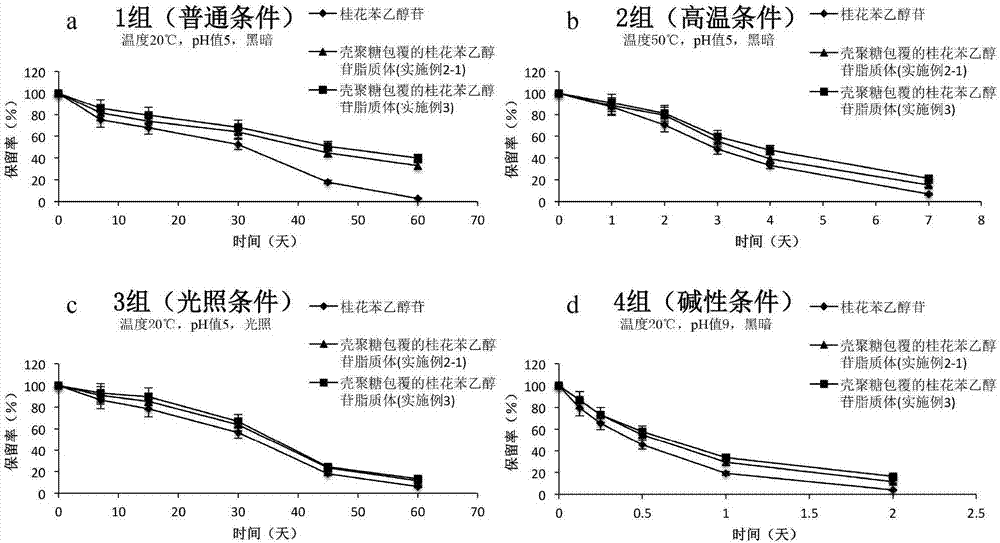

[0056] Weigh 1 g of soybean lecithin, 0.05 g of cholesterol, and 0.5 g of osmanthus phenylethanol glycoside, dissolve them in 50 mL of absolute ethanol, and sonicate for 10 min to obtain a uniform lipid ethanol solution. Rapidly inject the lipid ethanol solution into 2 times the volume of phosphate buffer solution (phosphate buffer solution with a pH value of 6.0 and a concentration of 0.01M) to obtain the osmanthus phenylethanol glycoside liposome suspension. Concentrate the suspension under reduced pressure (0.010 MPa, temperature is 40° C.), recover ethanol, and obtain osmanthus phenylethanol glycoside liposome solution (osmanthus phenylethanol glycoside nanoliposome solution). Weigh 100 mg of chitosan and dissolve (dissolve with magnetic stirring) in 100 mL of 1% (volume %) glacial acetic acid solution to obtain a chitosan solution. Add the above liposome solution dropwise (dropping time is 20-30 minutes) into the chitosan solution, the stirring speed of the magnetic stirr...

Embodiment 2

[0068] Weigh 1 g of soybean lecithin, 0.05 g of osmanthus phenylethanol glycoside, and 0.10 g of cholesterol, dissolve them in 50 mL of absolute ethanol, and sonicate for 10 min to obtain a uniform lipid ethanol solution. Rapidly inject the lipid ethanol solution into 2 times the volume of phosphate buffer solution (phosphate buffer solution with a pH value of 6.0 and a concentration of 0.01M) to obtain the osmanthus phenylethanol glycoside liposome suspension. Concentrate the suspension under reduced pressure (0.010 MPa, temperature is 40° C.), recover ethanol, and obtain osmanthus phenylethanol glycoside liposome solution (osmanthus phenylethanol glycoside nanoliposome solution). Weighing 100mg of chitosan was dissolved in 100mL of 1% glacial acetic acid solution to obtain a chitosan solution. The liposome solution was added dropwise into the chitosan solution, the stirring speed of the magnetic stirrer was 500 rpm / min during the whole process, and the mixed solution was inc...

Embodiment 3

[0080] Weigh 1 g of soybean lecithin, 0.10 g of osmanthus phenylethanol glycoside, and 0.10 g of cholesterol, dissolve them in 50 mL of absolute ethanol, and sonicate for 10 min to obtain a uniform lipid ethanol solution. Rapidly inject the lipid ethanol solution into 2 times the volume of phosphate buffer solution (phosphate buffer solution with a pH value of 6.0 and a concentration of 0.01M) to obtain the osmanthus phenylethanol glycoside liposome suspension. Concentrate the suspension under reduced pressure (0.010 MPa, temperature is 40° C.), recover ethanol, and obtain osmanthus phenylethanol glycoside liposome solution (osmanthus phenylethanol glycoside nanoliposome solution). Weighing 200mg of chitosan was dissolved in 100mL of 1% glacial acetic acid solution to obtain a chitosan solution. The liposome solution was added dropwise to the chitosan solution, the stirring speed of the magnetic stirrer was 500 rpm / min during the whole process, and the mixed solution was incub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com