Reaction type thermal conductive insulating double sided tape and preparation method thereof

A technology of heat conduction insulation and double-sided tape, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as low mechanical strength, poor solvent resistance, and environmental pollution, so as to improve application reliability and improve Thermal conductivity, the effect of overcoming environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

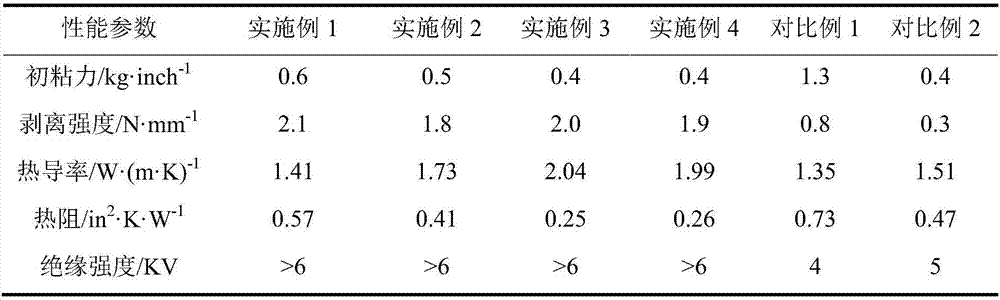

Examples

Embodiment 1

[0024] A preparation method of reactive thermally conductive and insulating double-sided adhesive tape, comprising the steps of:

[0025] S1. First, heat 150g of film-forming acrylic resin 8004 to 70°C, dissolve it in 150g of bisphenol A epoxy resin 828, and then add 15g of curing agent dicyandiamide and 3.0g of 2-phenylimidazole in sequence after cooling down to room temperature And mix evenly, then add 1500g of alumina (10 μm) in batches, continue to stir and mix evenly, and vacuum defoaming to obtain a thermally conductive adhesive layer matrix resin.

[0026] S2. Prepare the prepared heat-conducting adhesive base resin together with the 38 μm PET release film through a calender to form two 100 μm adhesive films.

[0027] S3. Finally, transfer the above-prepared adhesive film to both sides of a 25 μm PI film (polyimide film) through a transfer printing process to obtain a 225 μm reactive heat-conducting and insulating double-sided adhesive tape, such as figure 1 As shown, ...

Embodiment 2

[0029] A preparation method of reactive thermally conductive and insulating double-sided adhesive tape, comprising the steps of:

[0030] S1. First, heat 100g of film-forming acrylic resin 8003 to 70°C, dissolve it in 150g of o-cresol novolac epoxy resin NPCN-704, then add 35g of curing agent 4,4-diaminophenylsulfone, 3.0 g of 1-cyanoethyl-2-ethyl-4-methylimidazole was mixed uniformly, then 1200 g of aluminum oxide (40 μm) and 600 g of aluminum oxide (5 μm) were added in batches, and the mixture was uniformly stirred and vacuum defoamed to obtain Thermally conductive adhesive layer base resin.

[0031] S2. Prepare the prepared heat-conducting adhesive base resin together with the 38 μm PET release film through a calender to form two 100 μm adhesive films.

[0032] S3. Finally, transfer the above-prepared adhesive film to both sides of the 25 μm PI film through the transfer printing process to obtain a 225 μm thick reactive heat-conducting and insulating double-sided adhesive ...

Embodiment 3

[0034] A preparation method of reactive thermally conductive and insulating double-sided adhesive tape, comprising the steps of:

[0035] S1, first heat 100g film-forming material styrene-maleic anhydride graft copolymer SM3000 to 100°C, dissolve it in 100g o-cresol novolac epoxy resin NPCN-704 and 100g bisphenol F epoxy resin 170, Then cool down to room temperature, add 12g of curing agent adipic dihydrazide, 4.0g of organic urea and mix uniformly, then add 1200g of alumina (40μm) and 300g of boron nitride (0.5μm) in batches, continue to stir and mix evenly and vacuum Degassing to obtain a thermally conductive adhesive layer matrix resin.

[0036] S2. Prepare the prepared heat-conducting adhesive base resin together with the 38 μm PET release film through a calender to form two 100 μm adhesive films.

[0037] S3. Finally, transfer the above-prepared adhesive film to both sides of the 25 μm PI film through the transfer printing process to obtain a 225 μm thick reactive heat-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com