Method for preparing fermentation-flavored meal replacement jelly powder

A technology of fermented flavor and meal replacement fruit, applied in food freezing, functions of food ingredients, food heat treatment, etc., can solve problems such as excessive sugar intake and easy hunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

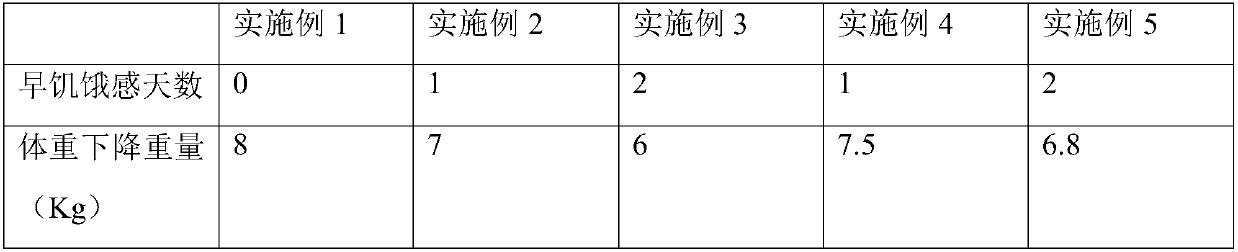

Examples

Embodiment 1

[0025] This embodiment provides a method for preparing a fermented-flavored meal replacement jelly powder, comprising the following steps:

[0026] (1) In parts by weight, get 55 parts of xylitol, 15 parts of linseed, 5.5 parts of jelly jelly seeds, 10.5 parts of citric acid, 15 parts of carrageenan, 15 parts of agar, 1.5 parts of gelatin and 5 parts of konjac powder and mix, Pass through a 100-mesh sieve after crushing to obtain primary mixed powder;

[0027] (2) Dissolving the primary mixed powder in 1000 parts of water, heating to 80-85°C, and cooling naturally until the primary mixed powder condenses into a gel-like product;

[0028] (3) Freezing the jelly product at -25°C for 16h, then refrigerating at 2°C for 3h, and then removing the precipitated moisture from the jelly product;

[0029] (4) Heat the jelly-like product to above 90°C, melt the jelly-like product, then add dietary fiber to it, and finally continue heating at a temperature of 95°C for 15 minutes, and then...

Embodiment 2

[0035] This embodiment provides a method for preparing a fermented-flavored meal replacement jelly powder, comprising the following steps:

[0036] (1) In parts by weight, take 50 parts of xylitol, 10 parts of flaxseed, 1 part of jelly jelly seed, 3 parts of citric acid, 10 parts of carrageenan, 10 parts of agar, 1 part of gelatin and 3 parts of konjac powder and pulverize Cross 100 mesh sieves to obtain primary mixed powder;

[0037] (2) Dissolving the primary mixed powder in 1000 parts of water, heating to 80°C, and cooling naturally until the primary mixed powder coagulates into a gel-like product;

[0038] (3) freezing the jelly product at -30°C for 12h, then refrigerating at 0°C for 2h, and then removing the precipitated moisture from the jelly product;

[0039] (4) Heat the jelly-like product to above 90°C, melt the jelly-like product, then add dietary fiber to it, and finally continue heating at a temperature of 90°C for 10 minutes, and then lower the temperature at a ...

Embodiment 3

[0045] This embodiment provides a method for preparing a fermented-flavored meal replacement jelly powder, comprising the following steps:

[0046] (1) In parts by weight, get 60 parts of xylitol, 20 parts of linseed, 10 parts of jelly jelly seeds, 18 parts of citric acid, 20 parts of carrageenan, 20 parts of agar, 2 parts of gelatin and 7 parts of konjac powder after pulverization Cross 100 mesh sieves to obtain primary mixed powder;

[0047] (2) Dissolving the primary mixed powder in 1000 parts of water, heating to 85° C., and cooling naturally until the primary mixed powder coagulates into a gel-like product;

[0048] (3) Freezing the gelatinous product at -20°C for 20h, then refrigerating at 4°C for 4h, and then removing the precipitated moisture from the gelatinous product;

[0049] (4) Heat the jelly-like product to above 90°C, melt the jelly-like product, then add dietary fiber to it, and finally continue heating at a temperature of 100°C for 20 minutes, and then reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com