Preparation method of salt-tolerant and stable type starch-based fluid-loss-resistant agent material

A stable, starch-based technology, used in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor salt tolerance and inability to meet demand, and achieve improved salt tolerance, improved filtration performance, The effect of strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

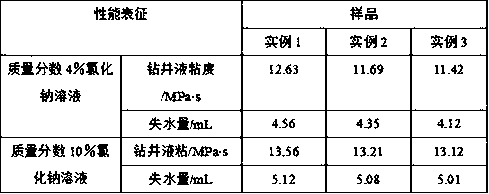

Examples

example 1

[0018] In parts by weight, weigh 45-50 parts of methacrylamidopropyltrimethylammonium chloride, 10-15 parts of deionized water, 2-3 parts of dibenzoyl peroxide, 0.5-1.0 parts of Potassium sulfate was placed in a three-necked flask, then heated in a water bath at 65-75°C for 2-3 hours, allowed to stand and cooled to room temperature, filtered and collected filter cake, vacuum freeze-dried and ground through a 200-mesh sieve to obtain a ground powder and use a mass fraction of 5 Wash with % sodium humate solution for 3 to 5 times, dry naturally and vacuum freeze-dry to obtain a modified gel; add the modified gel to deionized water at a mass ratio of 1:25, and then ultrasonicate at 200 to 300W Shake for 10-15 minutes to obtain a suspension and mix the suspension with a mass fraction of 1% copper chloride solution at a volume ratio of 1:1, let it stand for adsorption and swell for 16-18 hours, and then mix it at 1200-1500r / min After massaging for 2-3 hours, a homogeneous sol solut...

example 2

[0020] In parts by weight, weigh 45-50 parts of methacrylamidopropyltrimethylammonium chloride, 10-15 parts of deionized water, 2-3 parts of dibenzoyl peroxide, 0.5-1.0 parts of Potassium sulfate was placed in a three-necked flask, then heated in a water bath at 65-75°C for 2-3 hours, allowed to stand and cooled to room temperature, filtered and collected filter cake, vacuum freeze-dried and ground through a 200-mesh sieve to obtain a ground powder and use a mass fraction of 5 Wash with % sodium humate solution for 3 to 5 times, dry naturally and vacuum freeze-dry to obtain a modified gel; add the modified gel to deionized water at a mass ratio of 1:25, and then ultrasonicate at 200 to 300W Shake for 10-15 minutes to obtain a suspension and mix the suspension with a mass fraction of 1% copper chloride solution at a volume ratio of 1:1, let it stand for adsorption and swell for 16-18 hours, and then mix it at 1200-1500r / min After massaging for 2-3 hours, a homogeneous sol solut...

example 3

[0022]In parts by weight, weigh 45-50 parts of methacrylamidopropyltrimethylammonium chloride, 10-15 parts of deionized water, 2-3 parts of dibenzoyl peroxide, 0.5-1.0 parts of Potassium sulfate was placed in a three-necked flask, then heated in a water bath at 65-75°C for 2-3 hours, allowed to stand and cooled to room temperature, filtered and collected filter cake, vacuum freeze-dried and ground through a 200-mesh sieve to obtain a ground powder and use a mass fraction of 5 Wash with % sodium humate solution for 3 to 5 times, dry naturally and vacuum freeze-dry to obtain a modified gel; add the modified gel to deionized water at a mass ratio of 1:25, and then ultrasonicate at 200 to 300W Shake for 10-15 minutes to obtain a suspension and mix the suspension with a mass fraction of 1% copper chloride solution at a volume ratio of 1:1, let it stand for adsorption and swell for 16-18 hours, and then mix it at 1200-1500r / min After massaging for 2-3 hours, a homogeneous sol soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com