Coil structure electrothermal evaporation multi-layer filling fabric, manufacturing method and application

An electrothermal evaporation and coil technology, which is applied to multi-strand fabrics, fabrics, textiles and papermaking, etc., can solve the problems of small operation elasticity of equipment, large power consumption, low desalination efficiency, etc., so as to improve the water evaporation efficiency and increase the contact area. , the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

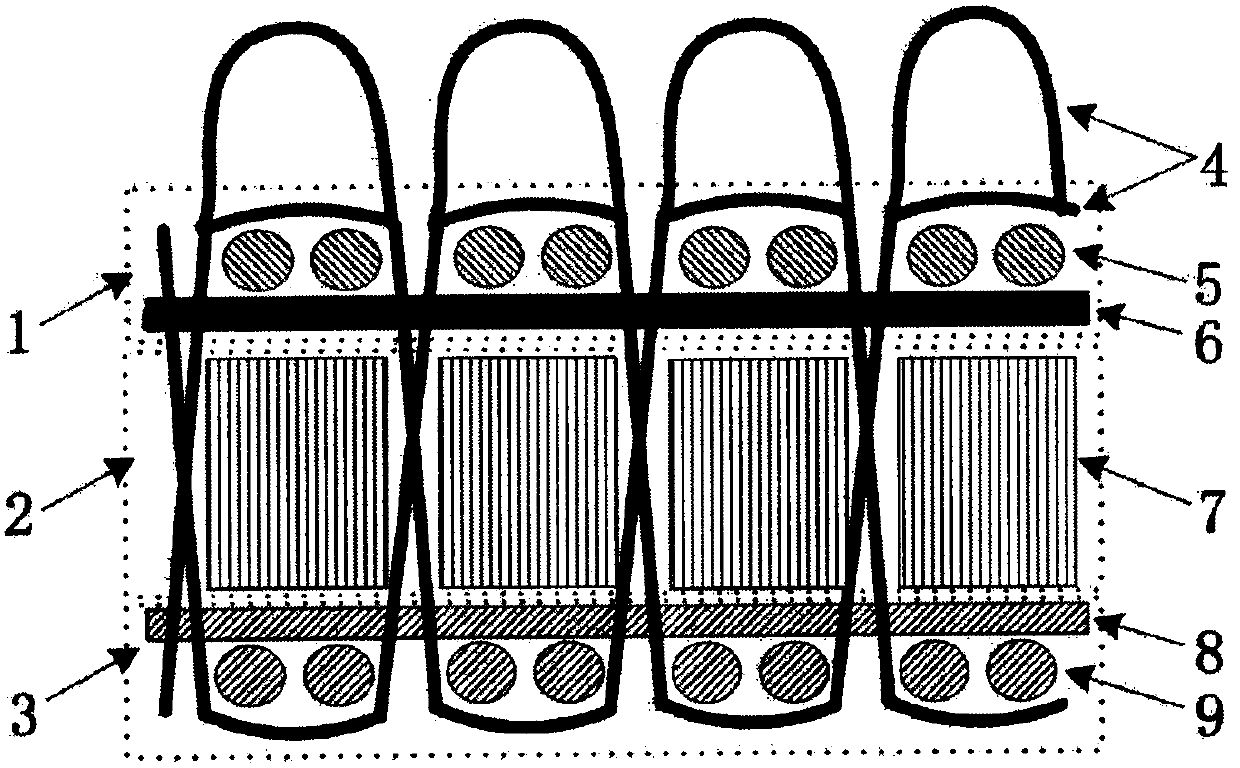

[0032] A carbon fiber electrothermal evaporation multilayer filled fabric disclosed in this embodiment selects T-300 carbon fiber (Toray Company, 12K) as the conductive fiber and 20 cotton fiber air textured yarns as the warp yarn 6 and weft yarn 5 of the electrothermal evaporation layer 1; A closed-cell foam sponge with a length of 10 cm, a width of 0.4 cm, a height of 0.5 cm, and a pore size of 10-20 microns is used as a floating embedded material 7 to form a floating insulation layer 2; 20 cotton fibers are selected as the warp yarn 8 and weft yarn 9 to weave water absorption Layer 3; 20 black ramie fiber air textured yarns are selected as binding yarn 4.

[0033] Using three-dimensional woven weaving technology, set the fabric width to 10 cm, warp and weft density: 5 threads / cm; binding yarn density: 2.5 threads / cm; set the feeding length of 1 / 10 binding yarns to 1 cm, and other yarns The feeding length and the take-up length of the fabric are 0.2 cm;

[0034] Weaving pro...

Embodiment 2

[0044] A nickel-plated carbon fiber electrothermal evaporation multi-layer filled fabric disclosed in this embodiment selects nickel-plated carbon fiber (Suzhou Jiedi Nano Technology Co., Ltd., 12K) and 25 cotton and linen blended air textured yarns as the warp yarn 6 and weft yarn 5 of the electrothermal evaporation layer 1 Select 10 centimeters in length, 1 centimeter in width, 0.6 centimeters in height, and a closed-cell foam sponge with a pore diameter of 10-20 microns as the floating embedding material 7 to form a floating insulation layer 2; 20 cotton fibers are used as warp yarn 8 and weft yarn 9 weaving Water-absorbing layer 3; select black 20-count regenerated cellulose fiber air textured yarn as binding yarn 4.

[0045] Three-dimensional woven weaving technology is adopted, the fabric width is set to 10 cm, warp and weft density: 10 threads / cm; binding yarn density: 2 threads / cm. Set the feeding length of 1 / 2 binding yarn to 1.5 cm, the feeding length of other yarns ...

Embodiment 3

[0056] A carbon nanotube yarn electrothermal evaporation multi-layer filling fabric disclosed in this embodiment selects a carbon nanotube film winding yarn with a diameter of 0.8 mm (Suzhou Jiedi Nano Technology Co., Ltd.) and a hydrophilic modified polyester bulked yarn of 1000tex As the warp yarn 6 and the weft yarn 5 of the electrothermal evaporation layer 1; the polyethylene hollow tube with a closed diameter of 0.5 cm at both ends and a hollowness of 80% is used as the floating embedded material 7 to form a floating heat insulation layer 2; 1000tex regenerated cellulose filament is selected as the Warp yarn 8 and weft yarn 9 weave water-absorbing layer 3; choose black 1000tex hydrophilic modified polyester bulky yarn as binding yarn 4.

[0057] Three-dimensional woven weaving technology is adopted, the fabric width is set to 10 cm, warp and weft density: 8 threads / cm; binding yarn density: 2 threads / cm. Set the feeding length of 9 / 10 binding yarns to be 2 cm, the feeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com