Method for synchronizing mesoporous heteroatom molecular sieves by means of photo-induced self-assembly

A heteroatom molecular sieve and self-assembly technology, applied in molecular sieves and base exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of limited metal elements, difficult promotion, cumbersome synthesis operations, etc., to achieve The effect of adjustable reaction time, fast curing rate and controllable light parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0023] Mix and stir 25 g of tetrabutyl titanate stabilized with acetylacetone, 1000 g of tetraethyl silicate, 100 g of P123 and 10 g of Irgacure 103 to obtain a coating solution;

[0024] Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

[0025] Use ultraviolet light with a wavelength of 350nm and an intensity of 50% to irradiate the liquid film coated on the substrate for photoreaction for 30 minutes, so that Irgacure 103 is decomposed, and a mesoporous heteroatom molecular sieve membrane containing template agent P123 is obtained;

[0026] Finally, the ultraviolet radiation with a wavelength of 350nm and an intensity of 80% was used to calcine for 60 minutes to remove the template agent P123 and obtain a mesoporous titanium-silicon molecular sieve membrane.

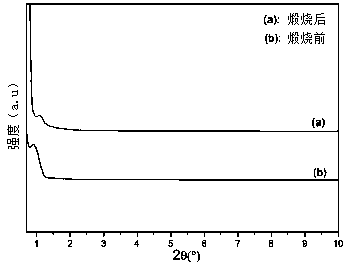

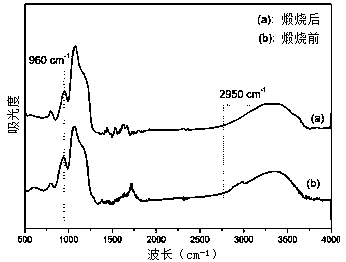

[0027] like figure 1 As shown, the mesopor...

Embodiment approach 2

[0029] Mix and stir 25 g of tetrabutyl titanate stabilized with acetylacetone, 1000 g of tetraethyl silicate, 250 g of P123 and 25 g of Irgacure 103 to obtain a coating solution;

[0030]Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

[0031] Use ultraviolet light with a wavelength of 390nm and an intensity of 20% to irradiate the liquid film applied on the substrate for photoreaction for 20 minutes, so that Irgacure 103 is decomposed, and a mesoporous heteroatom molecular sieve membrane containing template agent P123 is obtained;

[0032] Using ultraviolet radiation with a wavelength of 350nm and an intensity of 50% to calcine for 100min, remove the template agent P123, and obtain a mesoporous titanium-silicon molecular sieve membrane.

Embodiment approach 3

[0034] Mix and stir 25 g of tetrabutyl titanate stabilized with acetylacetone, 1000 g of tetraethyl silicate, 500 g of P123 and 50 g of Irgacure 103 to obtain a coating solution;

[0035] Under the condition of ambient humidity of 30-90%, apply the above-mentioned coating solution evenly on the porous ceramic substrate to form a liquid film, and the final thickness of the liquid film is controlled at 1-50 μm;

[0036] Use ultraviolet light with a wavelength of 420nm and an intensity of 90% to irradiate the liquid film coated on the substrate for photoreaction for 10 minutes, so that Irgacure 103 is decomposed, and a mesoporous heteroatom molecular sieve membrane containing template agent P123 is obtained;

[0037] Using ultraviolet radiation with a wavelength of 350nm and an intensity of 90% to calcine for 120min, remove the template agent P123, and obtain a mesoporous titanium-silicon molecular sieve membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com