An Application of Selective Laser Sintering Using Polyetheretherketone as Raw Material

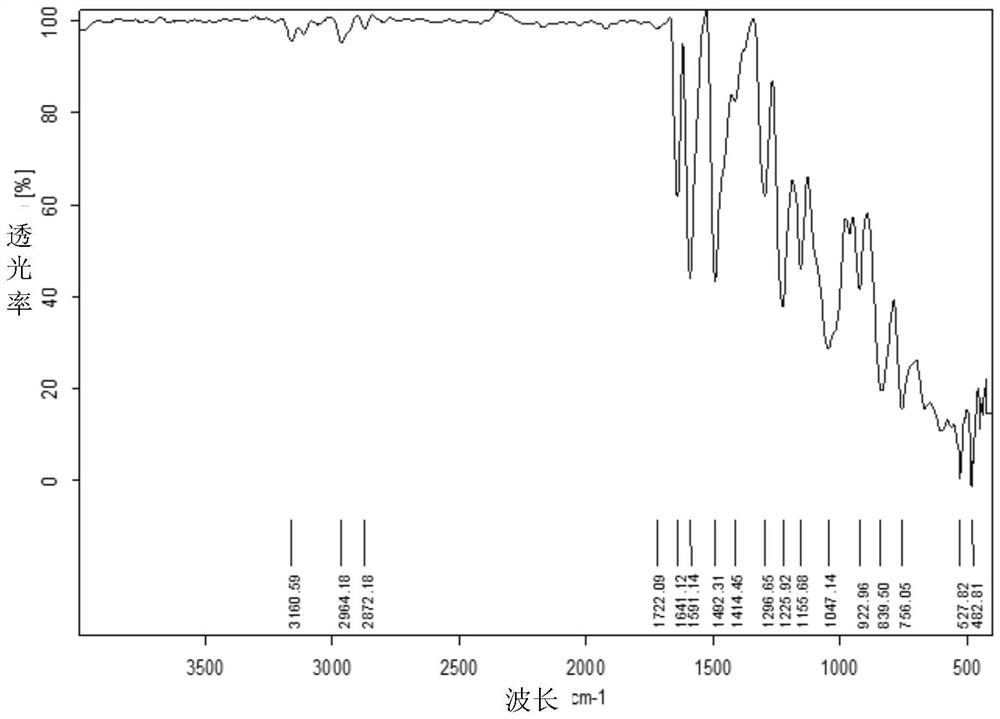

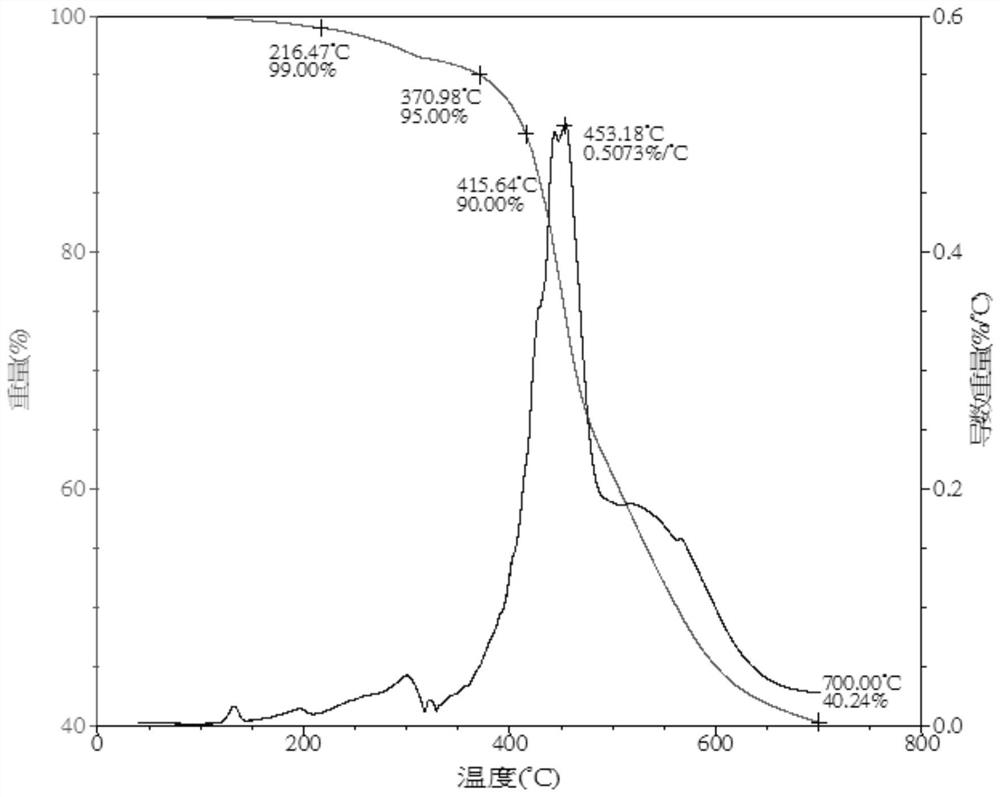

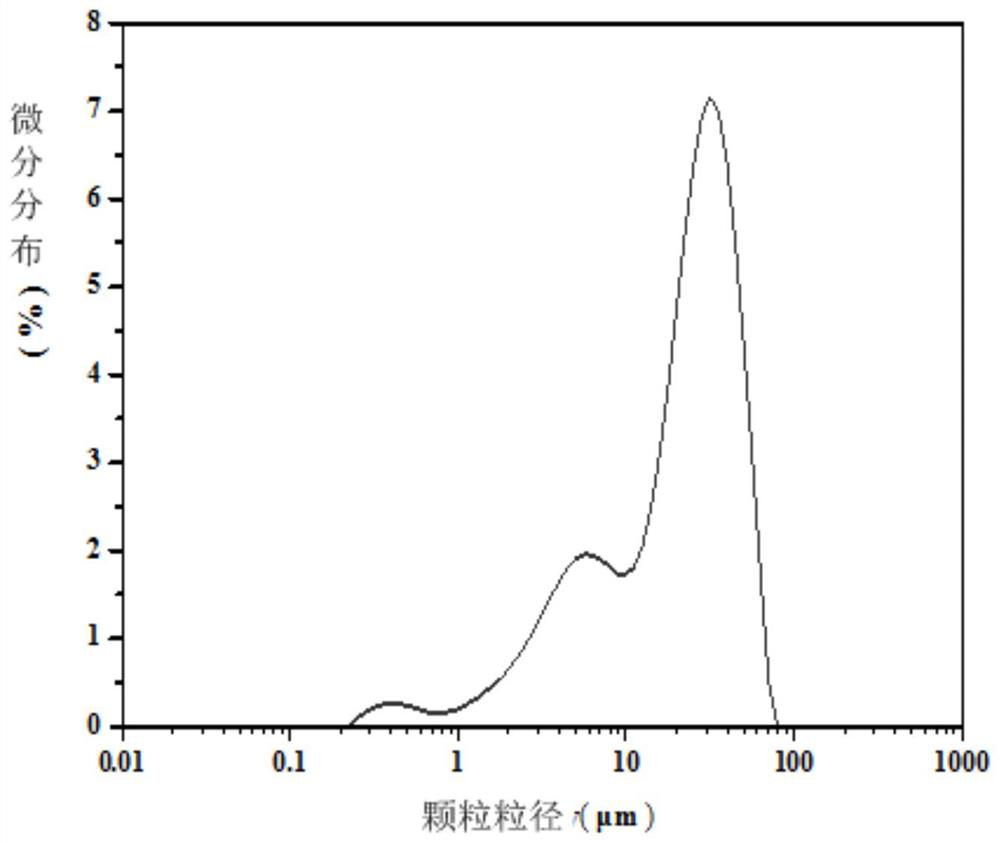

A technology of polyether ether ketone and laser sintering, which is applied in the direction of additive processing, etc., can solve the problems of rough surface, wide particle size distribution, and less spherical particles, and achieve the effect of high powder fluidity and convenient subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Under nitrogen protection, 10.90 g of 4,4'-difluorobenzophenone was added to a solvent of 1-butyl-3-methylimidazolic bromorine salt to give 4,4'-difluorobenzophenone. Solution, wherein the structure of 1-butyl-3-methylimidazolium bromide is The 4,4'-difluoroblovenate solution was warmed to 40 ° C, while stirring 4,4'-difluorobenzophenone solution to completely dissolve 4,4'-difluorobenzodone, cooled to Alternative to standing; under nitrogen protection, 5.50 g of 1,4-benzene and 0.69 g of potassium anhydrous carbonate and 4.77 g of anhydrous sodium carbonate are mixed and divided into four parts of the mass equal, and the 4,4'-two is added separately. In the fluorophenyl ketophenone solution, the high-speed stirring (the stirring speed can be 100 to 500 rpm), the interval of adjacent two additions is 30 min, from normal temperature to 140 ° C, and the temperature rise rate is 5 ° C / min, Insulation 2 h, allowing 4,4'-difluorobenzophenone, potassium anhydrous carbonate and...

Embodiment 2

[0040] Under argon, 218.00 g of 3,3'-difluorobenzophenone was added to a solvent of 1,3-di (2-methoxy-2-oxyethyl) imidazole, resulting in 4 , 4'-difluorobenzophenone solution, wherein the structure of 1,3-di (2-methoxy-2-oxyethyl) imidazole is: The 4,4'-difluoroblofluorophenone solution was raised to 25 ° C, and the mixture was stirred at 4,4'-difluorobenzophenone solution to completely dissolve 4,4'-difluorobenzodone, cooled to Alternative to standing; under argon protection, 22.83 g of bisphenol A and 1.38 g of anhydrous potassium carbonate and 9.64 g of anhydrous sodium anhydrous sodium carbonate were separated into four parts of mass equal, and 3,3'-difluoro is added separately. In the benzophenone solution, the high-speed stirring (the stirring speed can be 100 ~ 500 rpm), the interval of adjacent two additions is 20 min, from normal temperature to 120 ° C, the temperature rise rate is 10 ° C / min, heat insulation 1h Make 4,4'-difluorobenzophenone, potassium anhydrous carbo...

Embodiment 3

[0045] Under argon, 10.90 g of 4,4'-difluorobenzodone was added to a solvent of 327.00 g of 1,3-d (2-methoxy-2-oxyethyl) imidazoliazolite, A solution of 4,4'-difluorobenzophenone has been obtained, wherein the structure of 1,3-di (2-methoxy-2-oxyethyl) imidazole hexafluorophosphate is: The 4,4'-difluorobenzophenone solution was raised to 60 ° C, and the mixture was stirred at 4,4'-difluorobenzophenone solution to cool until normal temperature, under argon, will 16.02 g of 2,6-dihydroxaphthalene and 0.35 g of anhydrous anhydrous carbonate and 4.39 g of anhydrous sodium anhydrous sodium carbonate were partially formed into five parts of mass equal, and 4,4'-difluorobenzophenone solutions were added, respectively. Continuous high-speed stirring (the stirring speed can be 100 ~ 500 rpm), the interval between adjacent two additions is 40min, from normal temperature to 120 ° C, the temperature rise rate is 20 ° C / min, heat insulation 3h, so that 4, 4 ' - Difluorobenzophenone, potassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com