Preparation method and production equipment of ammonia caramel pigment

A production equipment, caramel color technology, applied in chemical instruments and methods, confectionery, confectionery industry, etc., can solve the problems of affecting the scope of use, growing tumors in animals, and poor storage capacity, so as to improve the anti-resinization ability and apply Wide, less foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

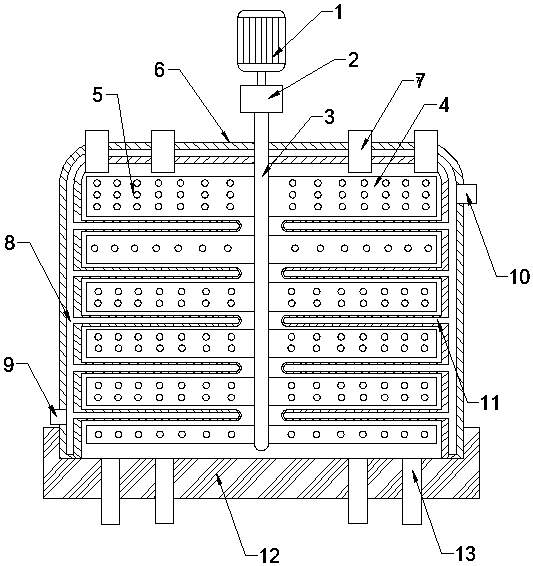

[0019] A production equipment for preparing ammonia-based caramel color, comprising a stirring motor 1, a reducer 2, a stirring shaft 3, an agitator 4, a through hole 5, a tank body 6, a feed port 7, an interlayer 8, and an interlayer feed port 9. Interlayer discharge port 10, heat distribution pipe 11, base 12, discharge port 13; wherein, the output end of the stirring motor 1 is equipped with a reducer 2, and the output end of the reducer 2 is equipped with a stirring shaft 3, and the stirring shaft 3 is connected to the stirring The mixer 4 is fixedly connected, the agitator 4 is provided with a through hole 5, the agitator shaft 3 passes through the tank body 6 and is flexibly connected to the upper end of the tank body 6, the upper end of the tank body 6 is also provided with a feed port 7, and the inner side of the tank body 6 is provided with an interlayer 8. The interlayer feed port 9 passes through the lower end on one side of the tank body 6 and communicates with the ...

Embodiment 2

[0024] A kind of preparation method of ammonia caramel color, 1000g sucrose is put into the production equipment described in embodiment 1, add the ammonium sulfite that the mass ratio of 30g is 6:1:2.5: ammonium acetate: glucoamylase mixture, then add Stir 1000g of water, raise the temperature to 100°C at a rate of 3°C, keep it warm for 45 minutes, cool it down to 85°C naturally, feed ammonia gas until the pressure in the tank is 0.3MPa, keep the pressure constant, and raise the temperature at 4°C Raise the rate to 155 degrees Celsius, after 4 hours of reaction, release the pressure, use circulating water to cool down to 95 degrees Celsius, add 0.5g of sucrose lipid, continue the reaction for 1.5 hours, cool to room temperature, discharge, press filter, concentrate to get coke sugar coloring.

Embodiment 3

[0026] A preparation method of ammonia caramel color, 1000g sucrose is put into the production equipment described in embodiment 1, the mass ratio that adds 50g is the ammonium sulfite of 6:1.5:2.5:1.5: ammonium acetate: glucoamylase: hydrogen Add 1000g of water to the mixture of sodium oxide, stir, raise the temperature to 100°C at a rate of 4°C, keep it warm for 30 minutes, cool it down to 75°C naturally, then feed ammonia gas until the pressure in the tank is 0.5MPa, then keep the pressure No change, the temperature rises to 165 degrees Celsius at a heating rate of 3 degrees Celsius, and after 6 hours of reaction, the pressure is released. After cooling to 115 degrees Celsius with circulating water, 0.3g of sucrose lipid is added, and after the reaction is continued for 1 hour, it is cooled to room temperature. Filter and concentrate to obtain caramel coloring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com