Preparation method of super-hydrophilic organic membrane based on surface covered with micro-nano structure

A technology of micro-nano structure and organic membrane, which is applied in the field of membrane separation, can solve the problems of rising operating costs and easy pollution of organic membranes, and achieve the effects of high-efficiency interception, excellent long-term anti-pollution performance, and high interception performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

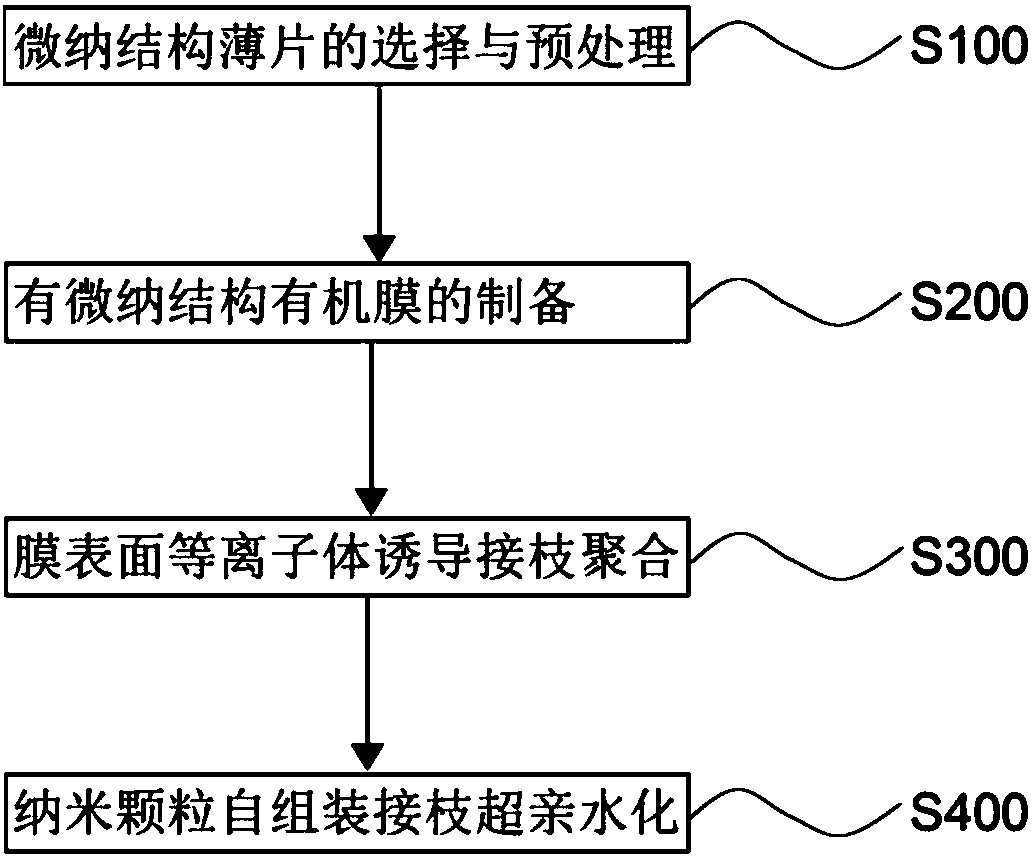

[0051] The present invention provides a method for preparing a super-hydrophilic organic film based on micro-nano structure imprinted on the surface. According to the embodiment of the present invention, the implementation flow chart is shown in figure 1 , including the following steps.

[0052] S100. Selection and pretreatment of micro-nano structured slices

[0053] According to an embodiment of the present invention, the sheet with a micro-nano structure on the surface includes, but is not limited to, a fine wire woven mesh and a polydimethylsiloxane with a complementary micro-nano structure on the surface prepared using the fine metal wire woven mesh as a template. The sheet is coated with a release agent with a thickness of no more than 0.1 micron on its surface, wherein the release agent is at least one of silicone compound, silicone oil, silicone grease, and surfactant.

[0054] S200. Preparation of organic film with micro-nano structure

[0055] Prepare a film castin...

Embodiment 1

[0061] 1. Selection and pretreatment of micro-nano structured slices

[0062] Select a fine metal wire braided mesh with a wire diameter of 0.8 microns as a template to prepare a polydimethylsiloxane sheet with a complementary micro-nano structure on the surface, and select chloromethyl dimethyl silicon chloride as a release agent for polydimethylsiloxane The surface of the siloxane flakes is coated with a coating thickness of 0.06 microns.

[0063] 2. Preparation of organic film with micro-nano structure

[0064] Based on the total mass of the casting solution, at room temperature (23 ± 2 degrees Celsius), fully dissolve 19wt% polyvinylidene fluoride and 0.5wt% polyvinylpyrrolidone in 80.5wt% N-methylpyrrolidone, and The resulting casting solution was allowed to stand for defoaming for 14 hours, then heated in a water bath at 50 degrees Celsius for 1 hour, and finally left to cool at room temperature. On the glass plate, use a scraper to make a layer of casting liquid film ...

Embodiment 2

[0071] 1. Selection and pretreatment of micro-nano structured slices

[0072] A fine metal wire braided mesh with a wire diameter of 0.8 microns is selected as a micro-nano structure sheet, and a surfactant is selected as a release agent to coat the surface of the sheet with a coating thickness of 0.06 microns.

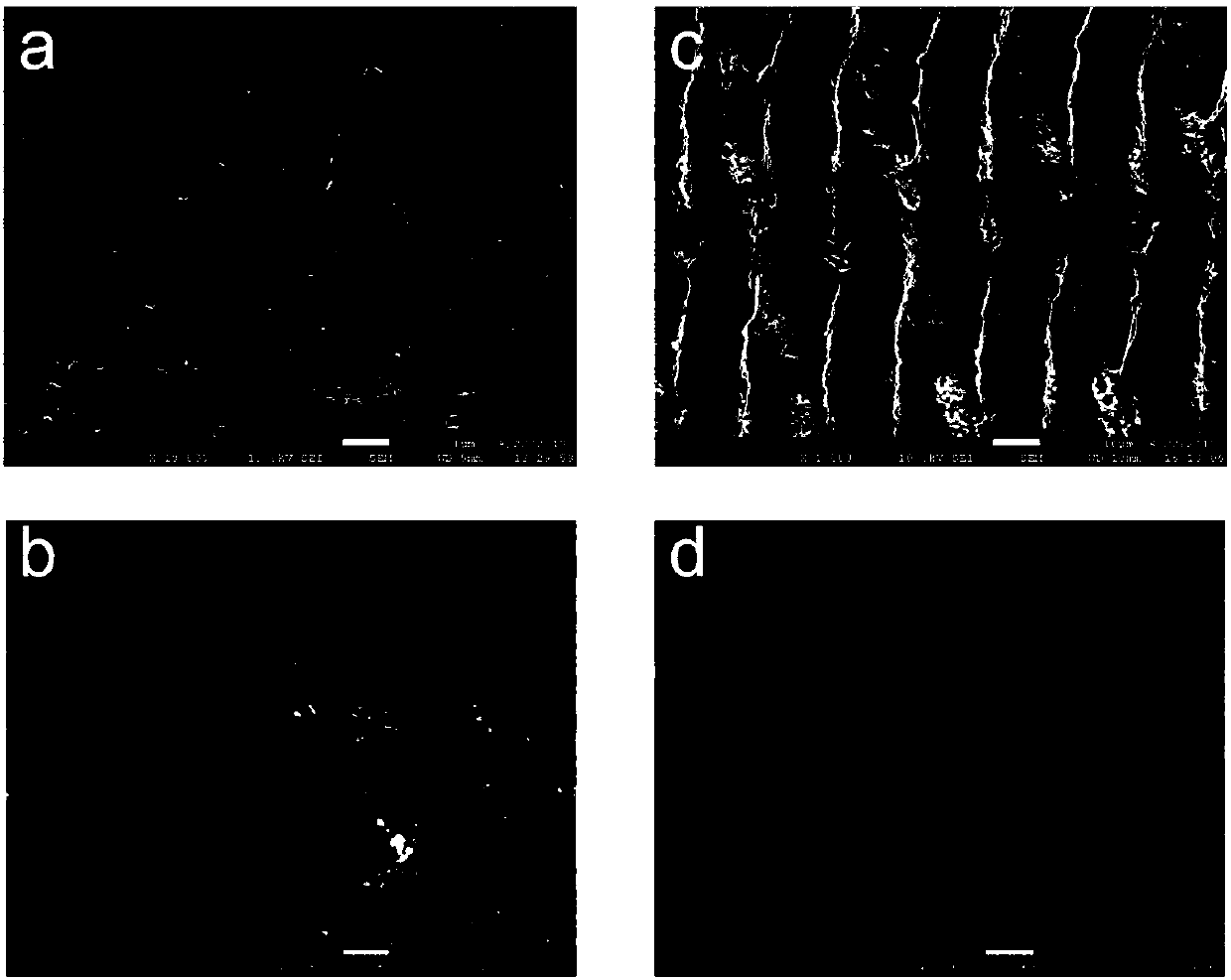

[0073] 2. Preparation of organic film with micro-nano structure

[0074] Based on the total mass of the casting solution, at room temperature (23 ± 2 degrees Celsius), fully dissolve 19wt% polyvinylidene fluoride and 0.5wt% polyvinylpyrrolidone in 80.5wt% N-methylpyrrolidone, and The resulting casting solution was allowed to stand for defoaming for 14 hours, then heated in a water bath at 50 degrees Celsius for 1 hour, and finally left to cool at room temperature. On the glass plate, use a scraper to make a layer of casting liquid film with a thickness of 200 microns, place a cushion layer with a height of 180 microns around the liquid film, and then cover the select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com