Preparation and application of greenly synthesized biochar supported zero-valent iron nanomaterial

A nano-zero-valent iron, green synthesis technology, applied in water pollutants, other chemical processes, water treatment parameter control and other directions, can solve the problems of easy oxidation of nanoparticles, unfavorable implementation and application, secondary pollution, etc. , enhance the stability, enhance the effect of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

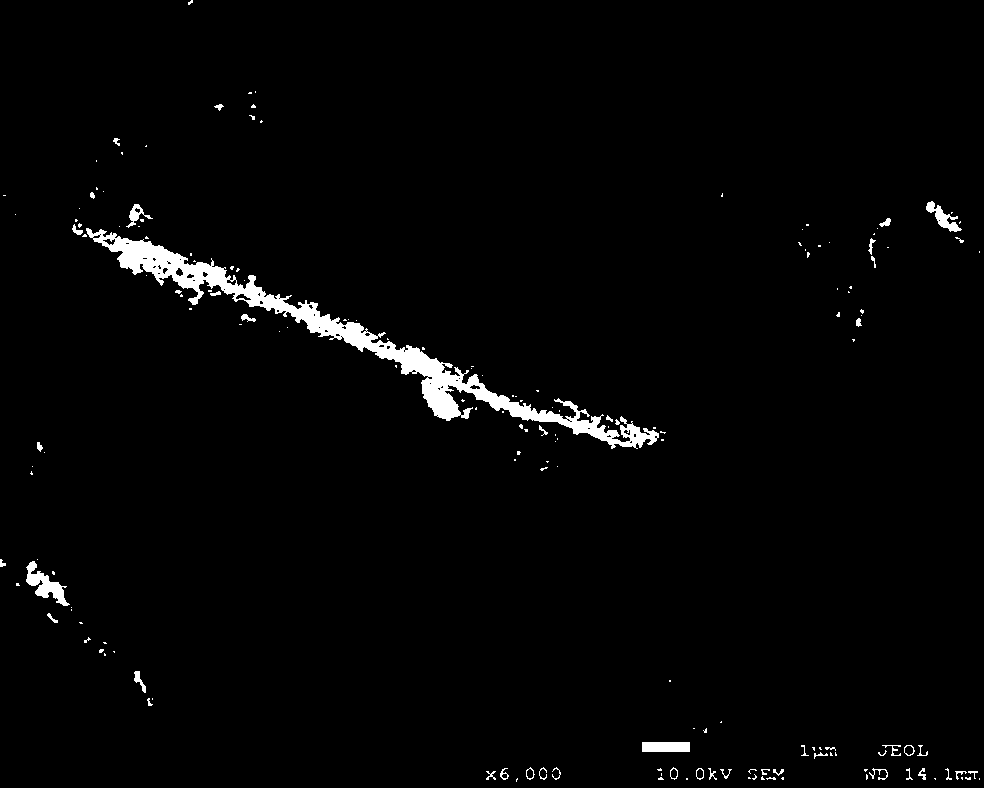

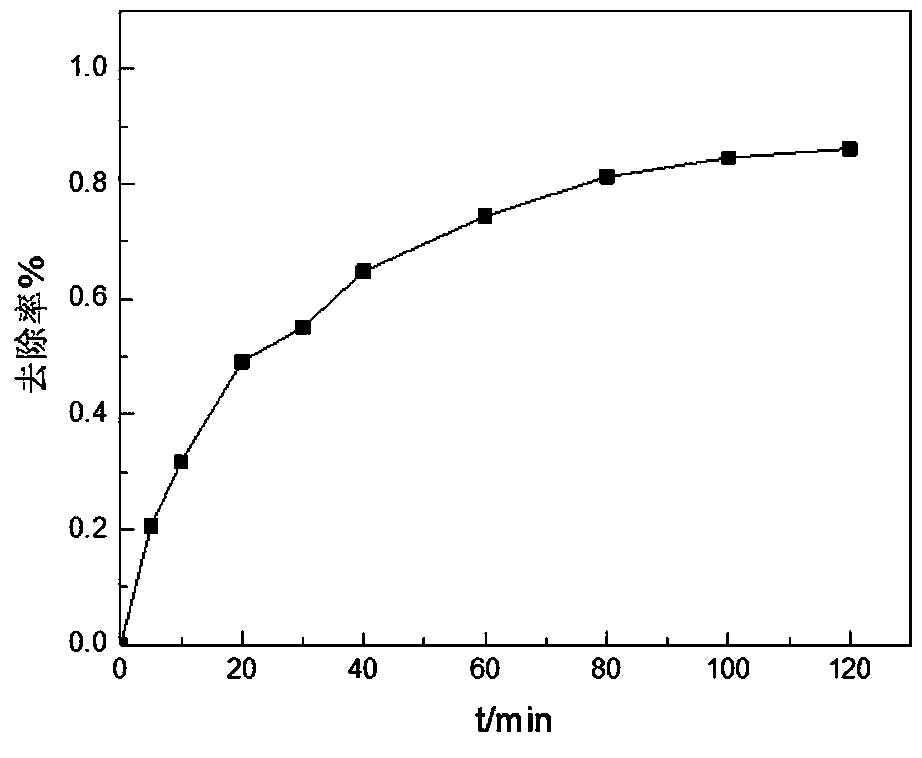

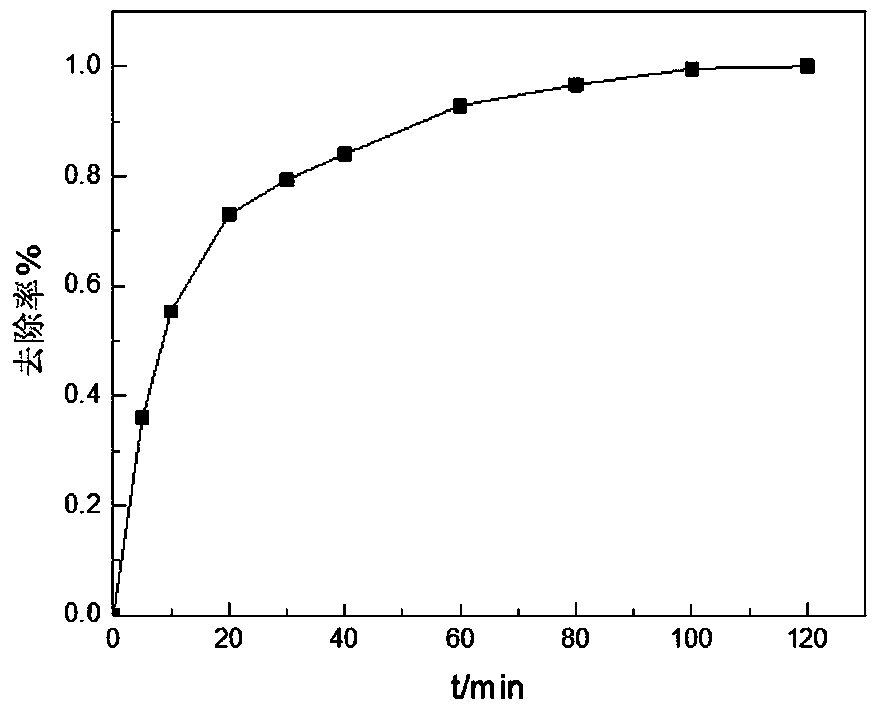

Image

Examples

preparation example Construction

[0037]In order to illustrate the present invention more clearly, the present invention provides a specific embodiment of a method for preparing a green synthetic biochar-loaded nano-zero-valent iron material. The preparation method of this embodiment includes the following steps:

[0038] (1) Preparation of biochar:

[0039] Put the crushed crop stalks into a muffle furnace, raise the temperature at 10-20°C / min to 300-700°C, keep the temperature constant for 7-14 hours, take it out to cool, grind, and pass through a 100-300 mesh screen to obtain a black powder.

[0040] Take 3-9g of black powder into a three-necked flask, then add 50-100mL of 1mol / L hydrochloric acid solution, heat in a water bath at 20-30°C, stir mechanically for 12-36 hours, filter, wash with distilled water until the pH is neutral, put Dry in a vacuum oven at 40-80°C for 48-60 hours, take it out, and obtain biochar powder;

[0041] (2) prepare green tea extract:

[0042] Weigh 10g-40g green tea and add it...

Embodiment 1

[0061] (1) Preparation of biochar:

[0062] Put the crushed corn stalks into a muffle furnace, raise the temperature at 20°C / min to 700°C, keep the temperature at a constant temperature for 6 hours, take it out, cool it down to room temperature naturally, grind it, and pass it through a 200-mesh sieve to obtain a black powder.

[0063] Take 5g of black powder into a three-necked flask, then add 50mL of 1mol / L hydrochloric acid solution, heat in a water bath at 25°C, stir mechanically for 12h, filter, wash with distilled water until the pH is neutral, and dry in a vacuum oven at 50°C 60h, take it out, obtain biochar powder, and set aside;

[0064] (2) prepare green tea extract:

[0065] Weigh 30g of green tea into 500mL of distilled water, heat in a water bath at 80°C for 100min, cool to room temperature, filter to obtain the green tea extract, and set aside;

[0066] (3) Preparation of biochar and iron ion mixed solution:

[0067] Add 0.125g of biochar powder and 6.25mmol o...

Embodiment 2

[0074] (1) Preparation of biochar:

[0075] Put the crushed wheat straw into a muffle furnace, heat up to 600°C at 10°C / min, keep the temperature for 10h, take it out, cool it down to room temperature naturally, grind it, and pass it through a 300-mesh sieve to obtain a black powder.

[0076] Take 4g of black powder into a three-necked flask, then add 50mL of 1mol / L hydrochloric acid solution, heat in a water bath at 25°C, stir mechanically for 36h, filter, wash with distilled water until the pH is neutral, and dry in a vacuum oven at 80°C 48h, take out, obtain biochar powder, set aside;

[0077] (2) prepare green tea extract:

[0078] Weigh 20g of green tea into 500mL of distilled water, heat in a water bath at 85°C for 90min, cool to room temperature, filter to obtain the green tea extract, and set aside;

[0079] (3) Preparation of biochar and iron ion mixed solution:

[0080] Add 0.125g of biochar powder and 6.25mmol of ferrous chloride to 50mL of distilled water, add i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com