Ag/UiO-66-NH2 composite material, and preparation method and application thereof

A uio-66-nh2, composite material technology, applied in catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of low conversion rate and inability to exhibit catalytic performance , the precious metal is not stable enough, etc., to achieve the effect of simple synthesis method and good reuse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

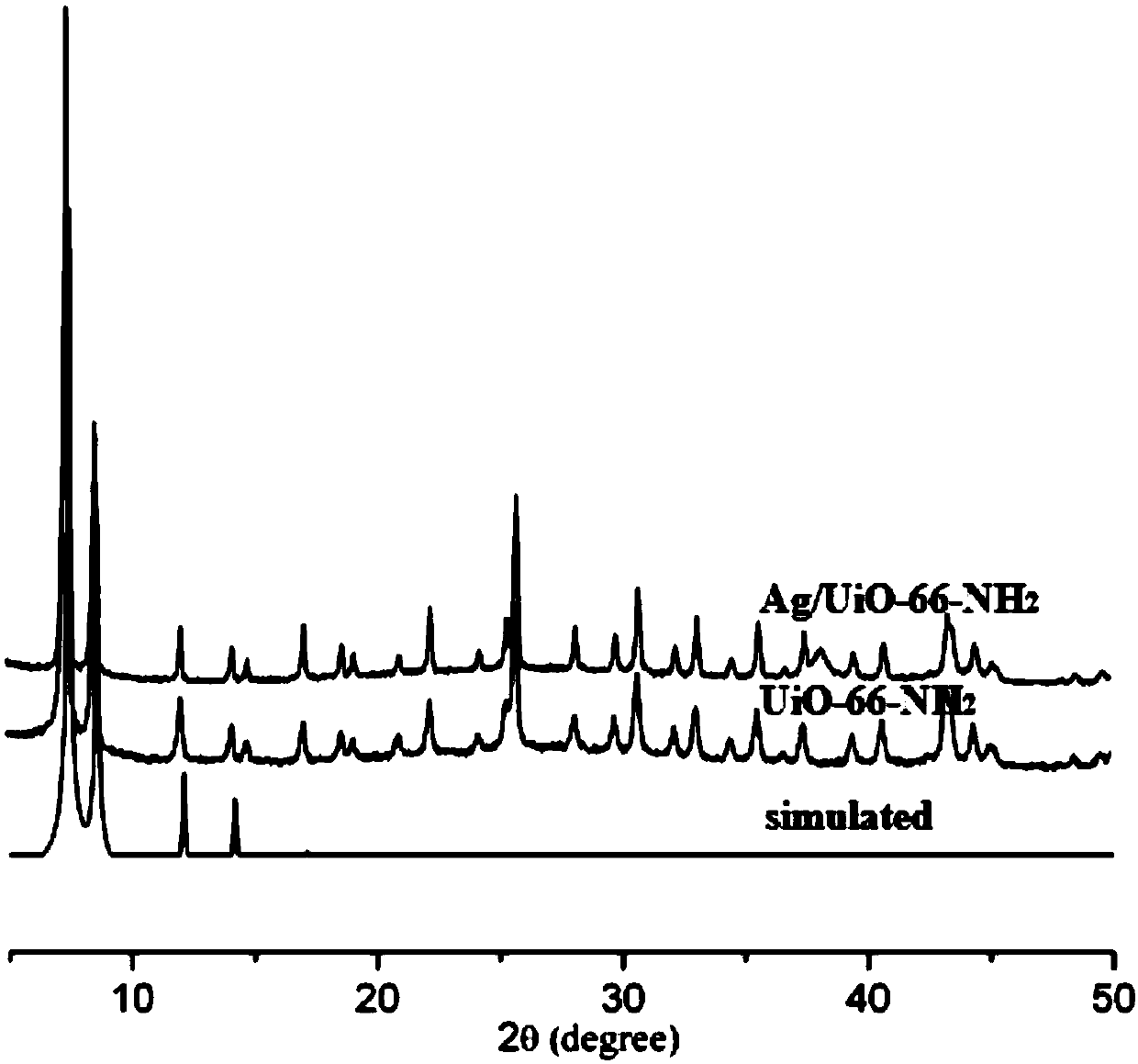

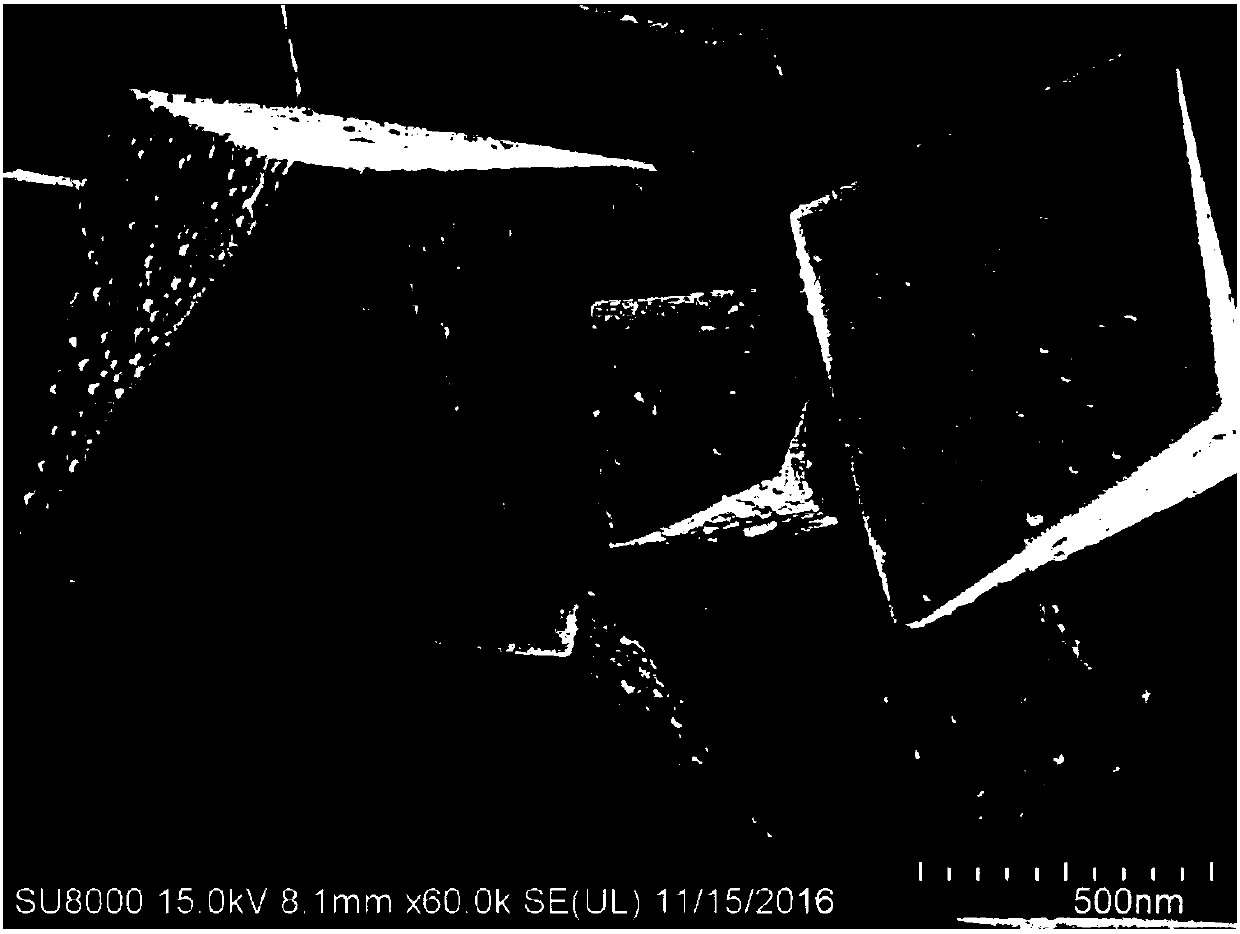

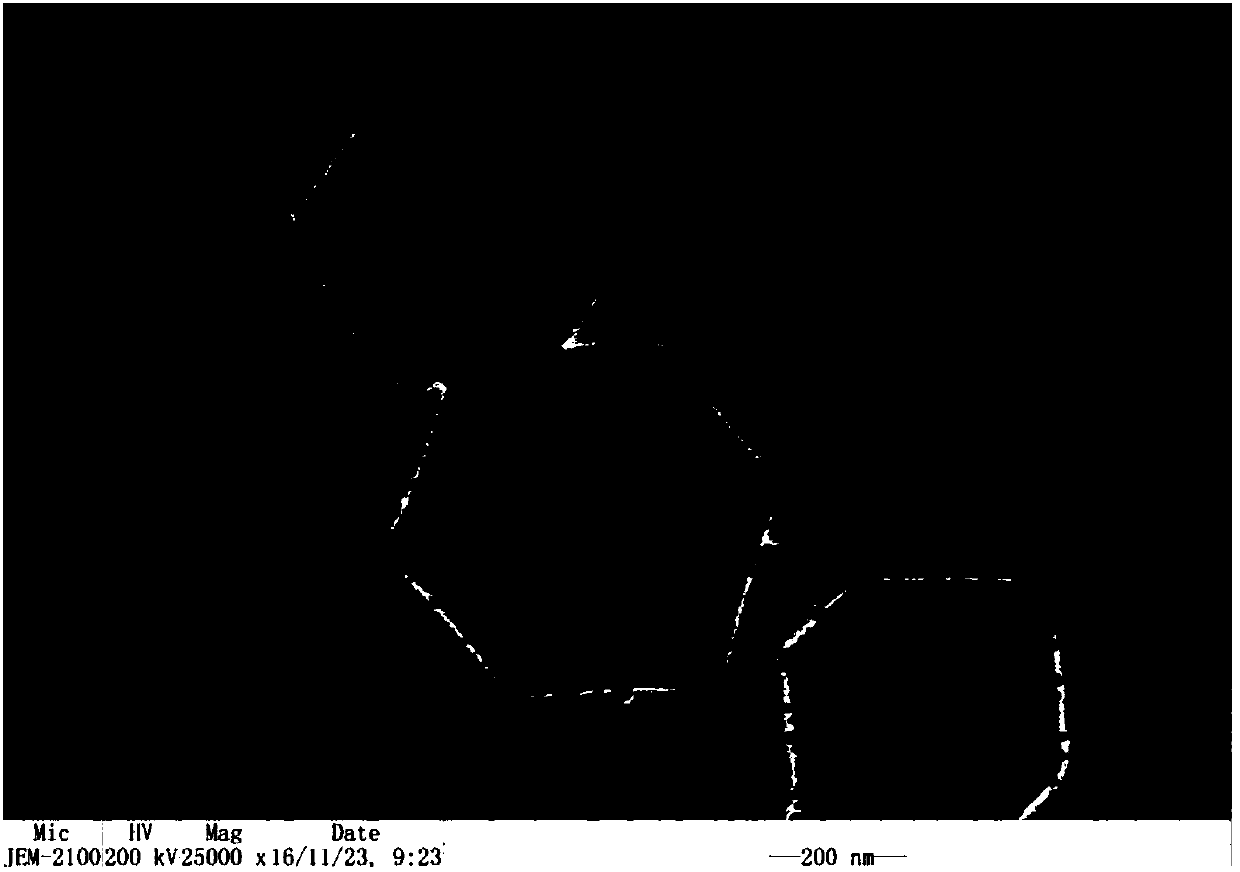

[0017] Example 1Ag / UiO-66-NH 2 composite material

[0018] (1) Preparation method

[0019] 1. UiO-66-NH 2 Preparation of crystals: 298.4mg of zirconium chloride and 232mg of 2-aminoterephthalic acid were placed in a hydrothermal synthesis reactor, and 30.0mL of acetic acid and 120mL of N,N-dimethylformamide (DMF) were added at the same time, and ultrasonic treatment 20 minutes, then put the hydrothermal synthesis reactor into an oven, and react at 120°C for 24 hours. After the reaction, remove the liquid in the solution and wash it with N,N-dimethylformamide. Put the solid into a methanol solution, let it stand overnight at room temperature, filter, put the solid particles into a vacuum drying oven at 80°C and dry under vacuum.

[0020] 2. UiO-66-NH 2 Crystal activation: UiO-66-NH 2 Put the crystal into a vacuum drying oven at 120°C for 24 hours in vacuum to obtain activated UiO-66-NH 2 Crystals, stored under nitrogen.

[0021] 3. Weigh 300 mg of silver nitrate solid pa...

Embodiment 2

[0026] Example 2Ag / UiO-66-NH 2 Selective Catalysis of Composite Materials for Styrene Reaction

[0027] The method is as follows: 10mmol (1.14ml) styrene and 30mmol (2.873ml) tert-butyl hydroperoxide are dissolved in 5ml of acetonitrile solution to obtain a mixed solution; the 50mg Ag / UiO- prepared in Example 1 is added to the mixed solution respectively 66-NH 2 Put the composite material in a 20mL eggplant-shaped reaction bottle, connect the condensing device, fix the reaction device, first insert the long needle below the liquid surface, pass nitrogen gas for 10 minutes, and remove the oxygen contained in the solution, then pull out the needle to use The whole reactor is sealed. React at a temperature of 80°C. After reacting for 18 hours, take the reaction solution and monitor it by gas chromatography. The results are as follows: Figure 4 shown.

[0028] Figure 4 Ag / UiO-66-NH synthesized for the present invention 2 In the gas phase diagram of the product after 0h and...

Embodiment 3

[0030] Example 3Ag / UiO-66-NH 2 Composite material repeatability test

[0031] After the reaction of Example 2 is finished, the Ag / UiO-66-NH 2 Composite material, repeat the experiment of embodiment 2 4 times. Figure 5 Ag / UiO-66-NH synthesized for the present invention 2The gas phase diagram of the product after 0h and 18h in the fifth catalyzed styrene oxidation reaction, through repeated experiments, Ag / UiO-66-NH reacted five times 2 The conversion rate of styrene in the composite material is 34.6%, and the selectivity of styrene oxide is 76.9%, which means that the material still has good catalytic activity and selectivity. Prove that the Ag / UiO-66-NH synthesized by the present invention 2 Composite materials have good recyclability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com