Preparation method and application of red carbon quantum dot with high quantum yield

A carbon quantum dot, high quantum technology, applied in the field of high quantum yield red carbon quantum dots and preparation, can solve the problems of weak light emission, low quantum yield, and difficulty in realizing three-primary color carbon quantum dots warm white LEDs, etc. High crystallinity, uniform particle size distribution and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

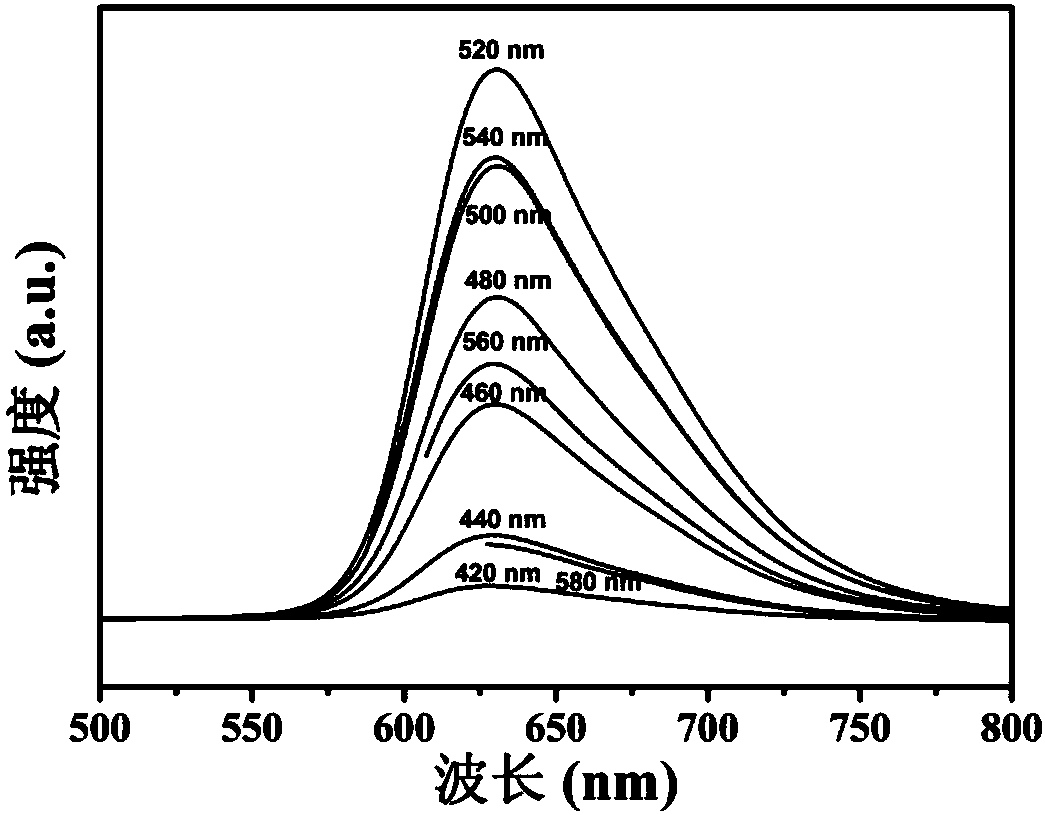

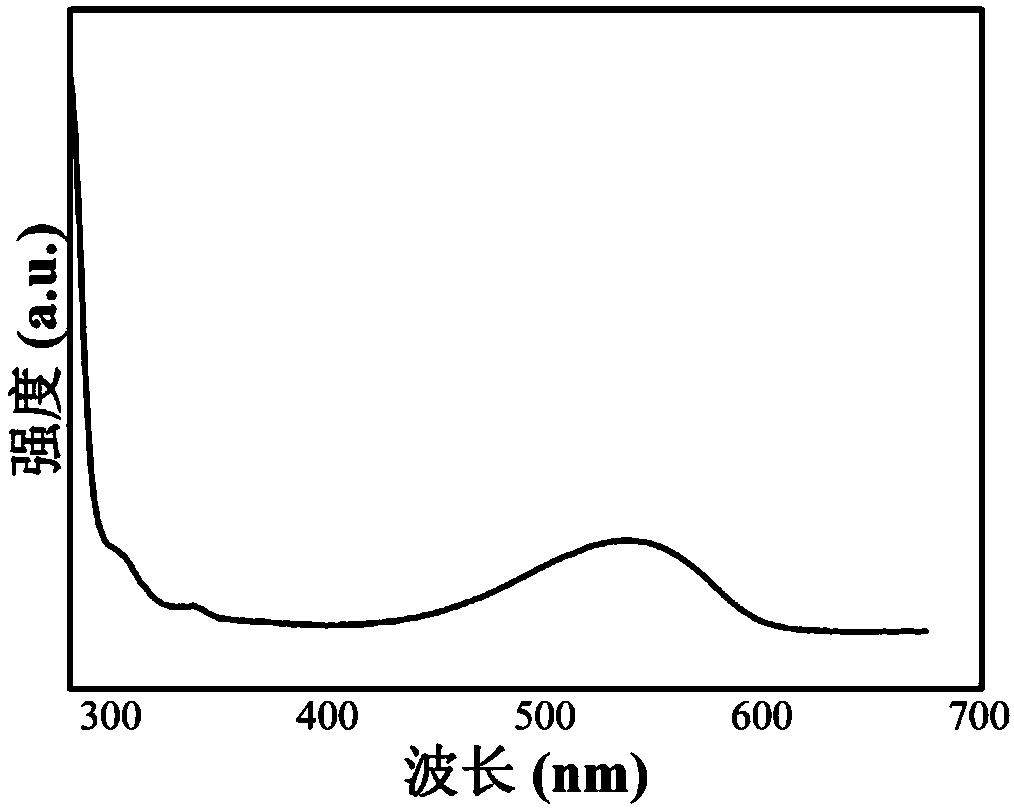

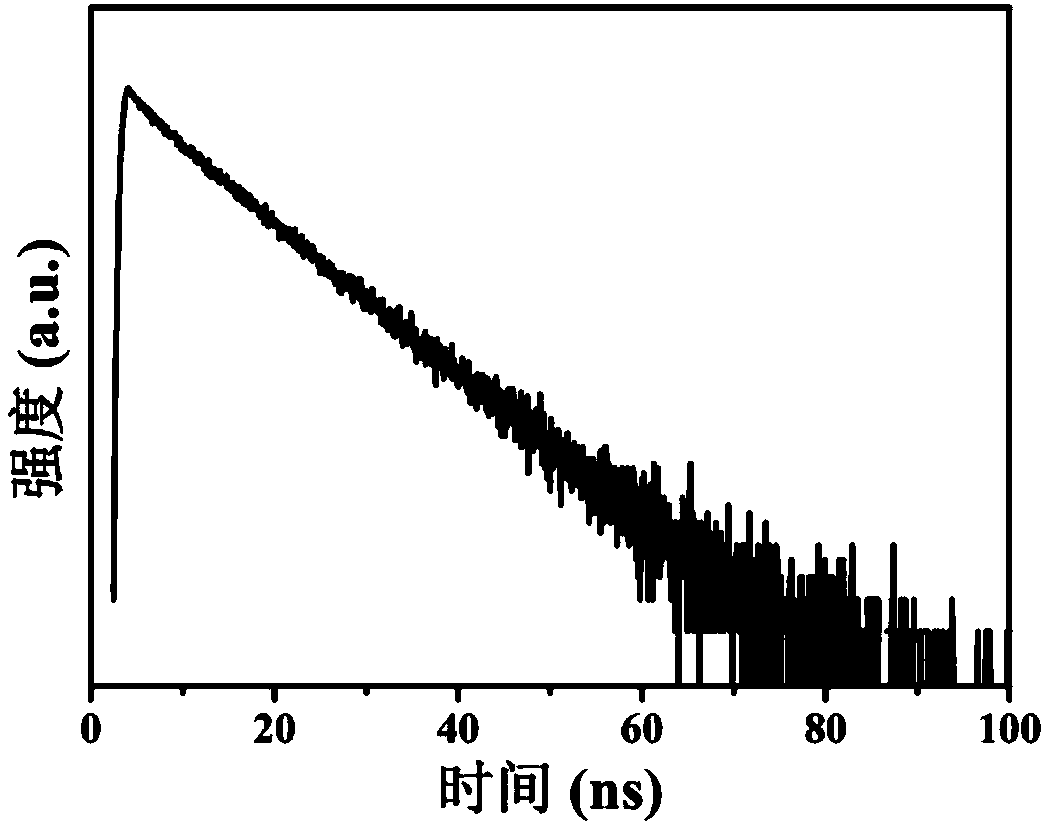

[0035] Embodiment 1, quantum yield is the preparation of 53% red carbon quantum dots:

[0036] Weigh 0.01 g and 0.04 g of 1,3-dihydroxynaphthalene and potassium periodate, respectively, with a mass ratio of 1:4, and dissolve them in 10 ml of ethanol with ultrasonic stirring. The above solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave with a capacity of 25 ml, and the lid of the autoclave was tightened. Solvothermal reaction was carried out at 180° C. for 0.5 hour, and then the reaction kettle was naturally cooled to room temperature, so as to obtain an ethanol solution of brown-red carbon quantum dots. Use methanol:dichloromethane (1:20~1:3) as the developer, silica gel as the filler, install a chromatographic column, spin the ethanol solution of the brown-red carbon quantum dots to dryness, dissolve in 1mL of the developer, and separate. Finally, red carbon quantum dots are obtained.

[0037] The dilute ethanol solution of the carbon quan...

Embodiment 2

[0040] Embodiment 2, quantum yield is the preparation of 50% red carbon quantum dots:

[0041] The specific steps are the same as in Example 1, except that the precursor 1,3-dihydroxynaphthalene and potassium periodate solids are 0.01 and 0.01 g respectively, and the mass ratio is 1:1. The obtained red carbon quantum dots have an absolute fluorescence quantum yield as high as 50%.

Embodiment 3

[0042] Embodiment 3, quantum yield is the preparation of 51% red carbon quantum dots:

[0043] The specific steps are the same as in Example 1, except that the volume-to-mass ratio of ethanol to 1,3-dihydroxynaphthalene is 1:5, and the obtained red carbon quantum dots have an absolute fluorescence quantum yield as high as 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com