Novel mould-proof silane modified polyether sealant and preparing method thereof

A technology of silane-modified polyether and anti-mildew silane is applied in the field of building sealant to achieve the effect of improving anti-mildew performance, good compatibility and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

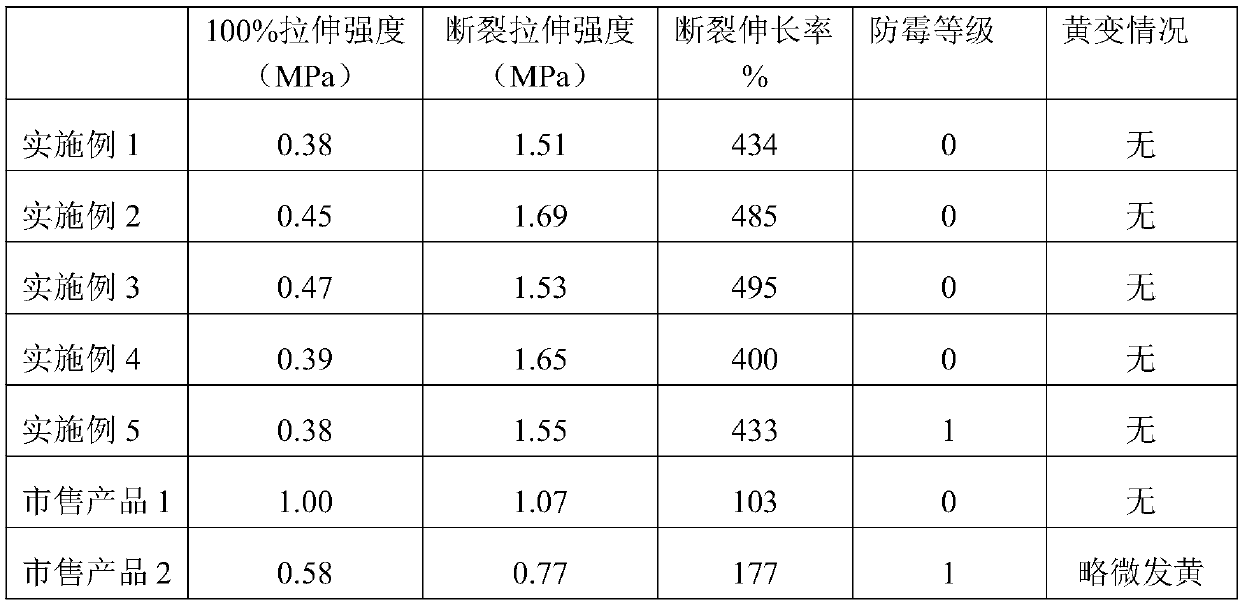

Examples

Embodiment 1

[0036]A novel mildew-resistant silane-modified polyether sealant, comprising the following raw materials in parts by weight: 90 parts of silane-modified polyether resin, 200 parts of active nano calcium carbonate, diisodecyl phthalate DIDP plasticizer 40 parts, 4 parts of titanium dioxide, 1 part of IRganox 1010 heat stabilizer, 3 parts of vinyltrimethoxysilane (A171) water remover, disulfide-2,2-bis(N-methylbenzamide) anti-mold 0.5 parts of agent, 1 part of silane bis(γ-trimethoxysilylpropyl) amine coupling agent (A1170) and 0.5 parts of chelated tin (U-220H) catalyst. The silane-modified polyether resin is a mixed modified polyether 12000DS with dimethoxysilane and trimethoxysilane, and its molecular weight is 10000.

[0037] Its preparation method comprises the following steps:

[0038] S1: Weigh each raw material according to the above ratio, add silane-modified polyether resin, active nano-calcium carbonate, diisodecyl phthalate DIDP plasticizer, titanium dioxide and IRg...

Embodiment 2

[0041] A novel mildew-proof silane-modified polyether sealant, comprising the following raw materials in parts by weight: 100 parts of silane-modified polyether resin, 180 parts of active nano-calcium carbonate, diisononyl phthalate DINP plasticizer 50 parts, 3 parts of titanium dioxide, 2.0 parts of IRganox 1010 heat stabilizer, 4 parts of vinyltrimethoxysilane (A171) water remover, disulfide-2,2-bis(N-methylbenzamide) anti-mold 0.4 parts of agent, 3 parts of KH792 coupling agent and 1.5 parts of dibutyltin dilaurate catalyst. The silane-modified polyether resin is a mixed modified polyether 12000DS with dimethoxysilane and trimethoxysilane, and its molecular weight is 15000.

[0042] Its preparation method comprises the following steps:

[0043] S1: Weigh each raw material according to the above ratio, add silane-modified polyether resin, active nano-calcium carbonate, diisononyl phthalate DINP plasticizer, titanium dioxide and IRganox 1010 heat stabilizer into the high-spe...

Embodiment 3

[0046] A novel mildew-resistant silane-modified polyether sealant, comprising the following raw materials in parts by weight: 110 parts of silane-modified polyether resin, 180 parts of active nano calcium carbonate, diisodecyl phthalate DIDP plasticizer 20 parts, 30 parts of polyether polyol N220 plasticizer, 2 parts of titanium dioxide, 2.0 parts of IRganox 1010 heat stabilizer, 2 parts of vinyltrimethoxysilane (A171) water remover, disulfide-2,2-bis (N-methylbenzamide) antifungal agent 0.3 parts, silane bis(γ-trimethoxysilylpropyl) amine coupling agent (A1170) 2 parts and dibutyltin dilaurate catalyst 2 parts. The silane-modified polyether resin is trimethoxysilane-modified polyether 30000T with a molecular weight of 20000.

[0047] Its preparation method comprises the following steps:

[0048] S1: Weigh each raw material according to the above ratio, and mix silane-modified polyether resin, active nano-calcium carbonate, diisodecyl phthalate DIDP plasticizer, polyether pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com