A kind of degradable shielding protective agent and its preparation method and application

A technology for shielding protection and raw materials, applied in the field of reservoir protective agent and shielding protective agent, can solve the problems affecting the dehydration of the gathering and transportation system, easy to get stuck on the pump, etc., and achieves good compatibility, good temperature resistance, and crosslinking time. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this example, a degradable shielding protective agent is prepared. The degradable shielding protective agent is 100% by weight. The raw materials of the degradable shielding protective agent are: 0.5% high-viscosity polyanionic cellulose PAC-HV, 4% amide modified starch Copolymer YX-I, 2.5% pitch, 0.7% coal gangue powder, 0.4% lignite, 4% sulfomethyl phenolic resin, 0.5% quaternary ammonium cationic starch ether CCS-03, 0.36% propylene glycol intercalation Segment polyether F38, 0.28% p-tert-butylphenol LY-I, 0.15% potassium polyacrylate (molecular weight 12 million) and the balance water.

[0024] The above-mentioned degradable shielding protective agent is prepared by the following steps:

[0025] Polyanionic cellulose, amide modified starch copolymer YX-I, asphalt, coal gangue powder, lignite, sulfomethyl phenolic resin, quaternary ammonium cationic starch ether, propylene glycol block polyether F38, p-tert-butyl phenol LY -I and potassium polyacrylate are added to wa...

Embodiment 2

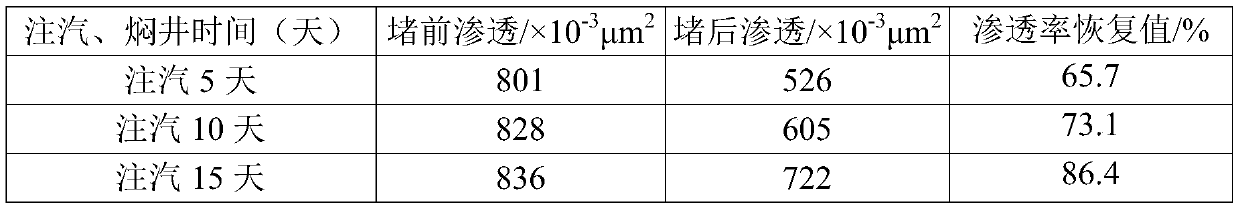

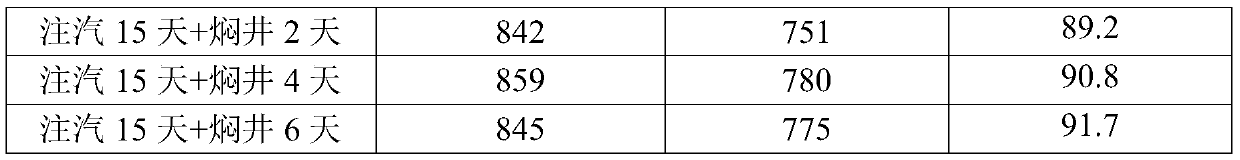

[0028] The degradable shielding protective agent of Example 1 was subjected to indoor core simulation experiments to test the permeability before and after plugging, and to investigate the temperature resistance and sealing strength of the protective agent. The experimental results are shown in Table 1.

[0029] Temperature resistance and plugging strength are verified according to the plugging rate index of the protective agent under different high temperature conditions. The plugging rate is the ratio of the core permeability before and after the protective agent to the permeability before the protective agent. The blocking effect of the blocking agent.

[0030] (1) Temperature resistance and blocking performance test

[0031] First evacuate the core, saturate it with formation water displacement fluid, measure the water permeability K1 of the core before plugging, then inject the protective agent of Example 1 into the core, and put the finished core into a distilled water In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com