Enzyme for degrading biogenic amine in soy sauce

A technology of soy sauce and multi-copper oxidase, which is applied in the field of fermentation, can solve the problems of low degradation efficiency, inability to guarantee the absolute singleness of production strains, difficulty in controlling miscellaneous bacteria, etc., and achieve the effect of high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

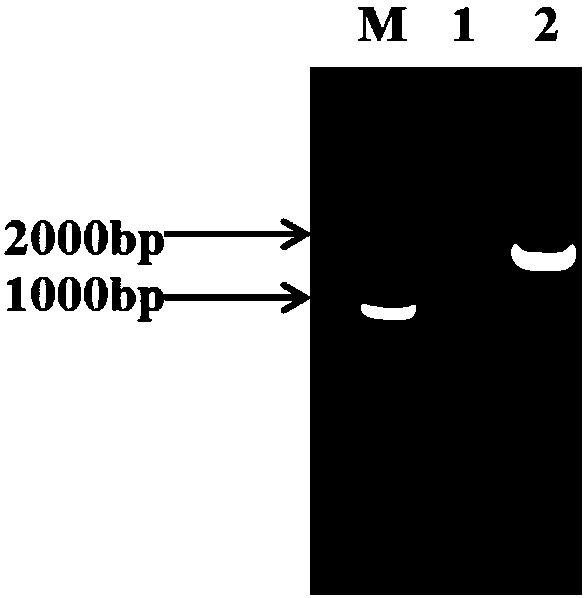

[0024] Example 1 High-throughput screening of bacterial strains containing multiple copper oxidase genes

[0025] 1. High-throughput screening of biogenic amine-free strains

[0026] Mix the moromi sample with sterile physiological saline, dilute it in different times and spread it on LB medium. After standing overnight at 37°C, select a suitable plate with a single colony. Add 1 mL of LB medium to each well plate in advance, pick single bacteria into a 96-well plate with a Qpix420 automatic bacteria picker, and culture them statically at 37°C for 24 hours. Then transfer to the biogenic amine detection liquid medium (the blank control is not inoculated), and observe the color change after standing at 37°C for 48 hours. If the color of the blank control does not change color, it is positive, and if it turns purple, it is negative. By using high-throughput screening technology, 70 positive strains were screened from 8000 strains.

[0027] 2. Screening of norbiometric strains ...

Embodiment 2

[0035] Degradation of biogenic amines in soy sauce by multi-copper oxidase crude enzyme in embodiment 2

[0036] Inoculate the screened bacterial strain containing the multi-copper oxidase gene to a concentration of 0.5-1mmol / LCu 2+ In the LB medium, 37°C, 220rmp / min, cultivate for 18-24h, after the cultivation is completed, centrifuge at 7000-10000r / min for 5-10min to collect the bacteria, repeat 2-3 times, and perform ultrasonic disruption. Filtrate and centrifuge the broken solution obtained, and concentrate the supernatant through a 3KD protein ultrafiltration tube to obtain a 3-5 times concentrated crude enzyme solution.

[0037] Mix 2ml of crude enzyme solution with 2mL of a certain brand of commercially available soy sauce, place the mixture in a 37°C incubator for 48h, centrifuge at 4°C and 10,000r / min for 5min to get the supernatant, and use HPLC to detect the content of biogenic amines Content Take 2ml of heat-inactivated crude enzyme solution and 2mL of commerciall...

Embodiment 3

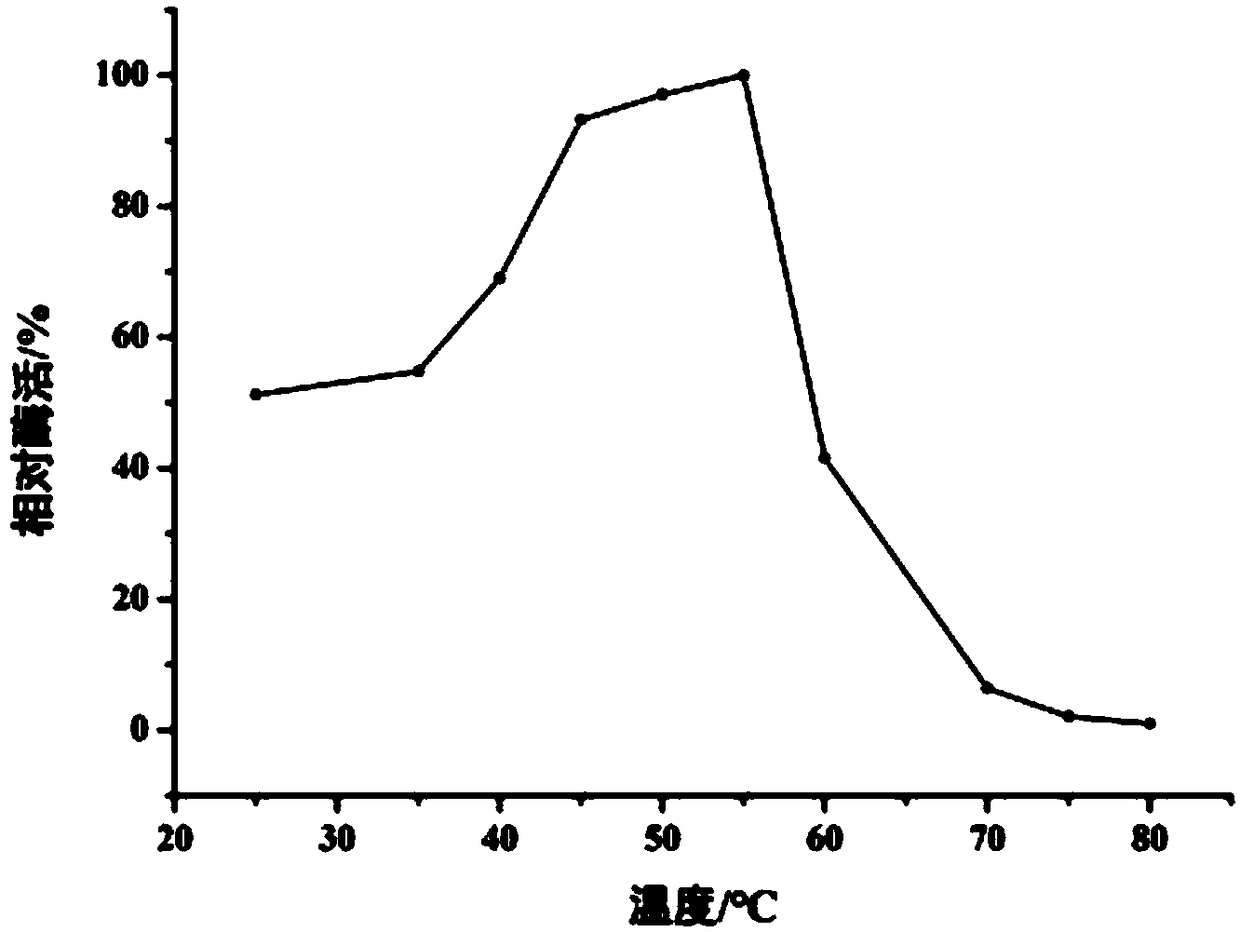

[0040] Enzymatic properties of embodiment 3 multi-copper oxidase crude enzyme

[0041] (1) Optimum temperature for multi-copper oxidase

[0042]The crude enzyme solution and the substrate were reacted for 10 minutes in a water bath at 25, 35, 40, 45, 50, 55, 60, 70, and 80°C respectively, and the enzyme activity was determined to determine the optimum reaction temperature of the enzyme. is 100%. The result is as image 3 It is shown that when the temperature is 45-55°C, the enzyme is relatively stable, and the activity can maintain more than 90% of the enzyme activity at the optimum temperature.

[0043] (2) Optimum pH of multi-copper oxidase

[0044] Prepare buffers with different pH: citrate buffer pH 2.2-6.0, phosphate buffer pH 6.0-8.5. React at 55°C for 10 minutes at different pH, and measure the enzyme activity at different pH conditions after the reaction is over to determine the optimum reaction pH. Take the highest enzyme activity as 100%. The result is as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com