Zinc-doped nickel oxide hole transport layer reserve perovskite solar cell and preparation method

A technology of hole transport layer and solar cell, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low conductivity and change, achieve optimized performance, high conductivity, increase light transmittance and hole extraction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The schematic diagram of the structure of the traditional inverted planar heterojunction solar cell is as follows: figure 1 . Cut the FTO transparent conductive glass into 1.6cm long strips, stick a tape with a width of one centimeter, etch with zinc powder and dilute hydrochloric acid with a volume ratio of concentrated hydrochloric acid to water of 1:5 for 15 minutes, and clean the residue with dilute hydrochloric acid zinc powder, cut the etched glass into 1.6×1.7cm rectangles, ultrasonically clean with lye for 30-60 min, then ultrasonically clean with alcohol for 30-60 min, and finally clean with deionized water for 10-30 min, Then put it into the drying box to dry for later use;

[0027] (2) Dissolve nickel nitrate in a mixed solvent of ethylenediamine and ethylene glycol, then place the mixed precursor solution on a magnetic stirrer and stir for twelve hours, obtain a clear solution after filtration, and then spin-coat the nickel oxide precursor solution for...

Embodiment 2

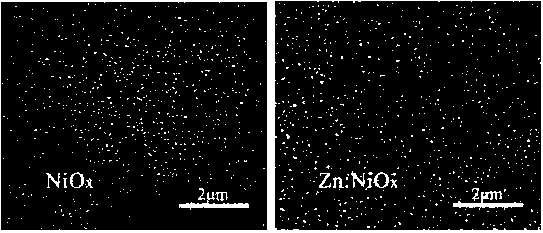

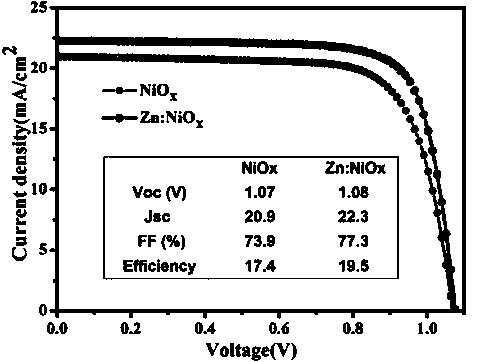

[0031] This embodiment is the same as Example 1, except that in step 2, nickel nitrate and zinc nitrate are mixed in a mixed solvent of ethylenediamine and ethylene glycol in proportion, wherein the zinc nitrate molar ratio is 3%, (the nitric acid The molar ratio of zinc to nickel nitrate is 3:97, the volume ratio of ethylenediamine and ethylene glycol is 1:10, and the concentration of zinc nitrate and nickel nitrate in the mixed solvent is 1M.) Then put the mixed precursor solution under magnetic force Stir on the stirrer for 12 hours, filter to obtain a clear solution, then spin-coat the mixed precursor solution of zinc nitrate and nickel nitrate on the fluorine-doped tin oxide glass (FTO glass) substrate for 40 seconds, and finally put the obtained substrate into a rapid annealing furnace Annealing at 400 °C for 3600 s to obtain zinc-doped nickel oxide films such as figure 2 (right).

Embodiment 3

[0033] This embodiment is the same as Example 2, except that in step 2, nickel nitrate and zinc nitrate are mixed in a mixed solvent of ethylenediamine and ethylene glycol in proportion, wherein the zinc nitrate molar ratio is 5%, (the nitric acid The molar ratio of zinc to nickel nitrate is 5:95, the volume ratio of ethylenediamine and ethylene glycol is 1:10, and the concentration of zinc nitrate and nickel nitrate in the mixed solvent is 1M.) Then put the mixed precursor solution under magnetic force Stir on the stirrer for 12 hours, filter to obtain a clear solution, then spin-coat the mixed precursor solution of zinc nitrate and nickel nitrate on the fluorine-doped tin oxide glass (FTO glass) substrate for 40 seconds, and finally put the obtained substrate into a rapid annealing furnace Zinc-doped nickel oxide film was obtained by annealing at 400°C for 3600s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com