Multi-level recycling pressure swing adsorption rapid oxygen-nitrogen generating device and method

A pressure swing adsorption and rapid technology, applied in the direction of oxygen preparation, separation methods, chemical instruments and methods, etc., can solve the problems of increased power total work, high cost of oxygen production, uncontrollable content, etc., to achieve long start-up time, reduce The effect of shortening power and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

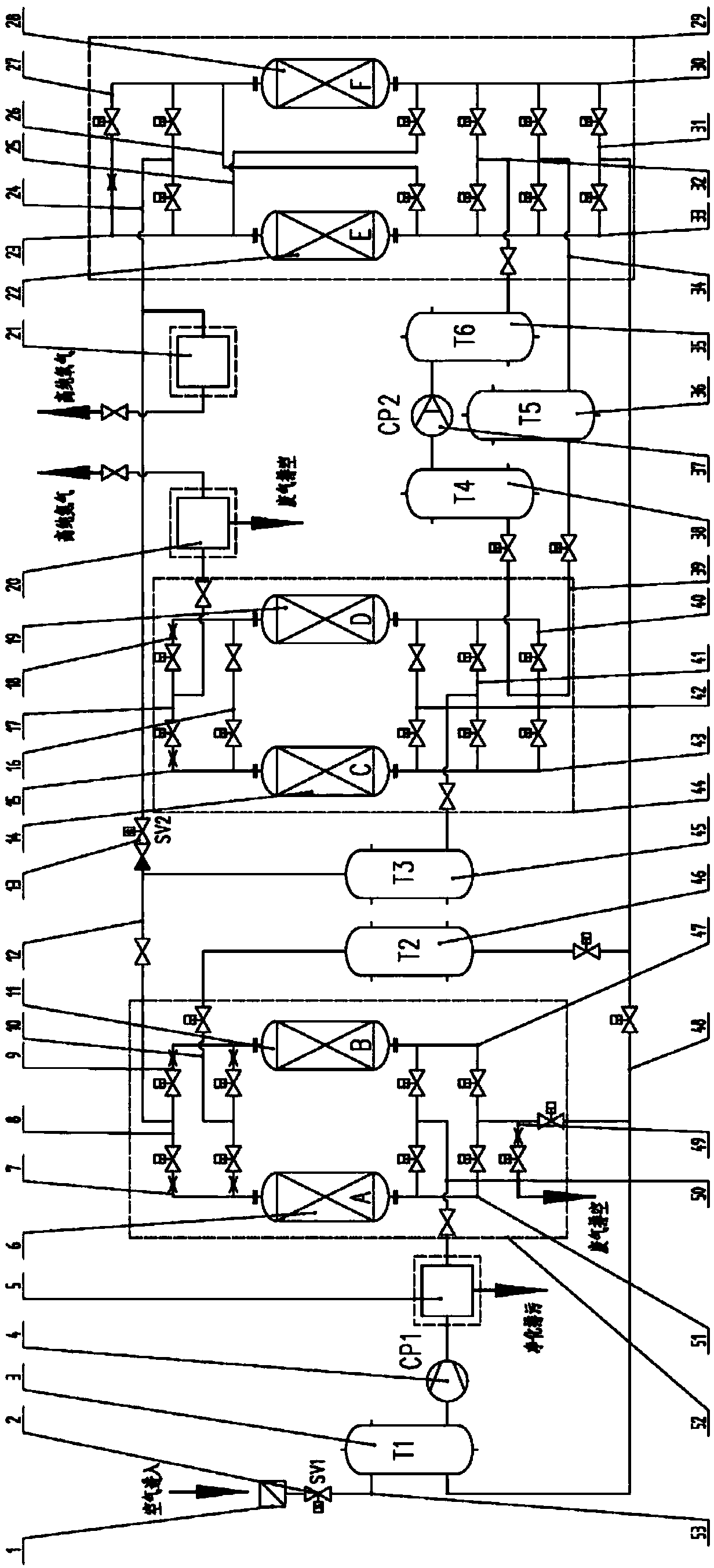

[0023] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention. In the attached picture. In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples.

[0024] like figure 1 The shown equipment for rapid production of high-quality oxygen and nitrogen based on multi-stage recovery pressure swing adsorption air separation mainly includes air filter 1, air inlet solenoid valve SV1 2, air inlet buffer tank T1 3, compressor CP1 4, Compressed air purification system 5, gas drying and purification system 52, oxygen-enriched purification tail gas recovery tank T2 46, buffer tank T3 45 after drying, high-purity oxygen speed-up pipeline 12, solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com