A method for preparing ultrafine amorphous calcium carbonate in alcohol-water mixed system

A technology of amorphous calcium carbonate and calcium amino acid, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for material and surface science, nanotechnology, etc. problems, to achieve the effect of a large range of controllable conditions, cheap and easy-to-obtain raw materials, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: Using calcium glycinate as raw material, the volume ratio of ethanol and calcium solution is 3: 1, and the molar ratio of calcium ion and magnesium ion is 5: 1 to prepare amorphous calcium carbonate

[0059] Measure 30mL of absolute ethanol in a three-necked flask, then add 10mL of 1mol / L calcium glycinate solution to the flask, and add 2mL of 1mol / L MgCl to the solution 2 solution, so that the molar ratio of calcium ions and magnesium ions in the solution is 5:1, after stirring evenly, introduce CO 2 , until the pH value of the solution was 7.5, stop feeding CO 2 . Immediately suction-filter the obtained calcium carbonate slurry, wash with absolute ethanol or alcohol-water mixture, and dry the obtained calcium carbonate in a vacuum oven at 60° C. for 24 hours to obtain 0.96 g of calcium carbonate product. The purity of the obtained product is 97.9%, and the yield is 96%.

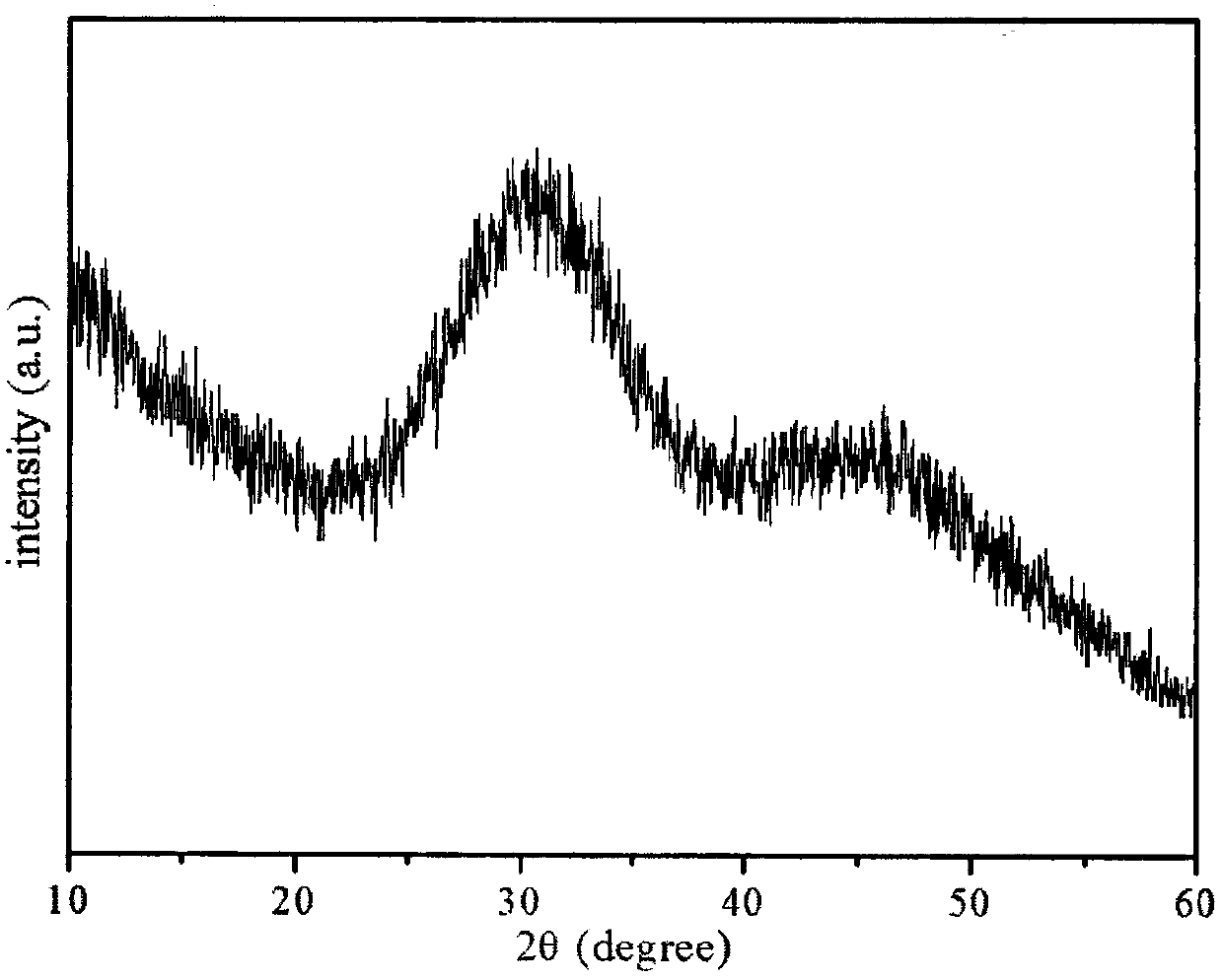

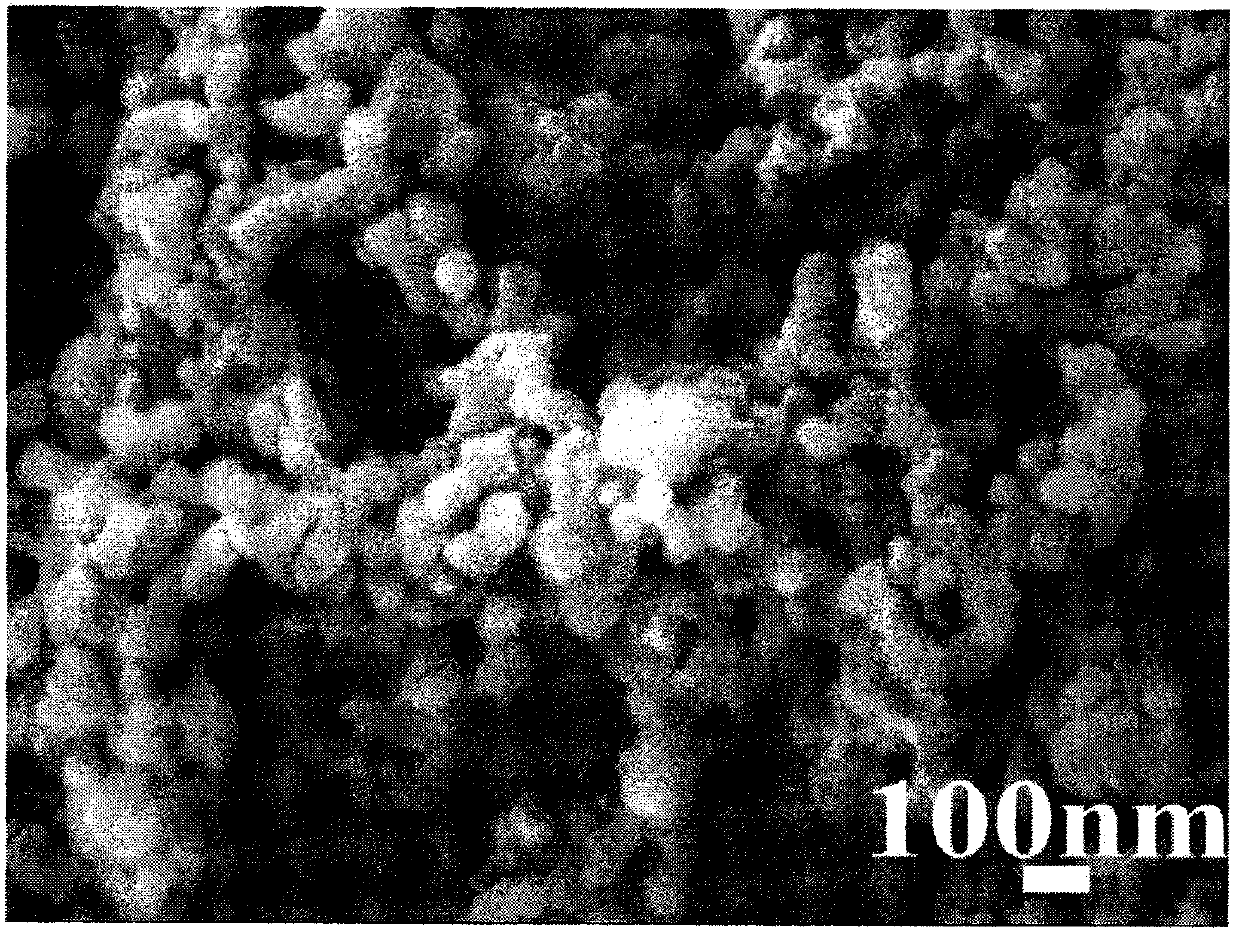

[0060] The products obtained after the reaction were characterized by X-ray diff...

Embodiment 2

[0061] Embodiment 2: Using calcium glycinate as raw material, different volume ratios of ethanol and calcium solutions, and the molar ratio of calcium ions and magnesium ions to prepare amorphous calcium carbonate under the conditions of 5:1

[0062] Measure 30mL of absolute ethanol in five three-necked flasks, and then add 5mL, 10mL, 15mL, 30mL, and 60mL of 1mol / L calcium glycinate solutions into the flasks, and the numbers are 1, 2, 3, and 4 respectively. , 5. Add 1mL, 2mL, 3mL, 6mL, 12mL of 1mol / L MgCl to the 5 solutions 2 solution, so that the molar ratio of calcium ions and magnesium ions in the solution is 5:1. After stirring evenly, inject CO 2 , until the pH value of the solution was 8, stop feeding CO 2 . Suction filter the obtained calcium carbonate slurry immediately, wash with absolute ethanol or alcohol-water mixture, and dry the obtained calcium carbonate in a vacuum oven at 60° C. for 24 hours to obtain the product.

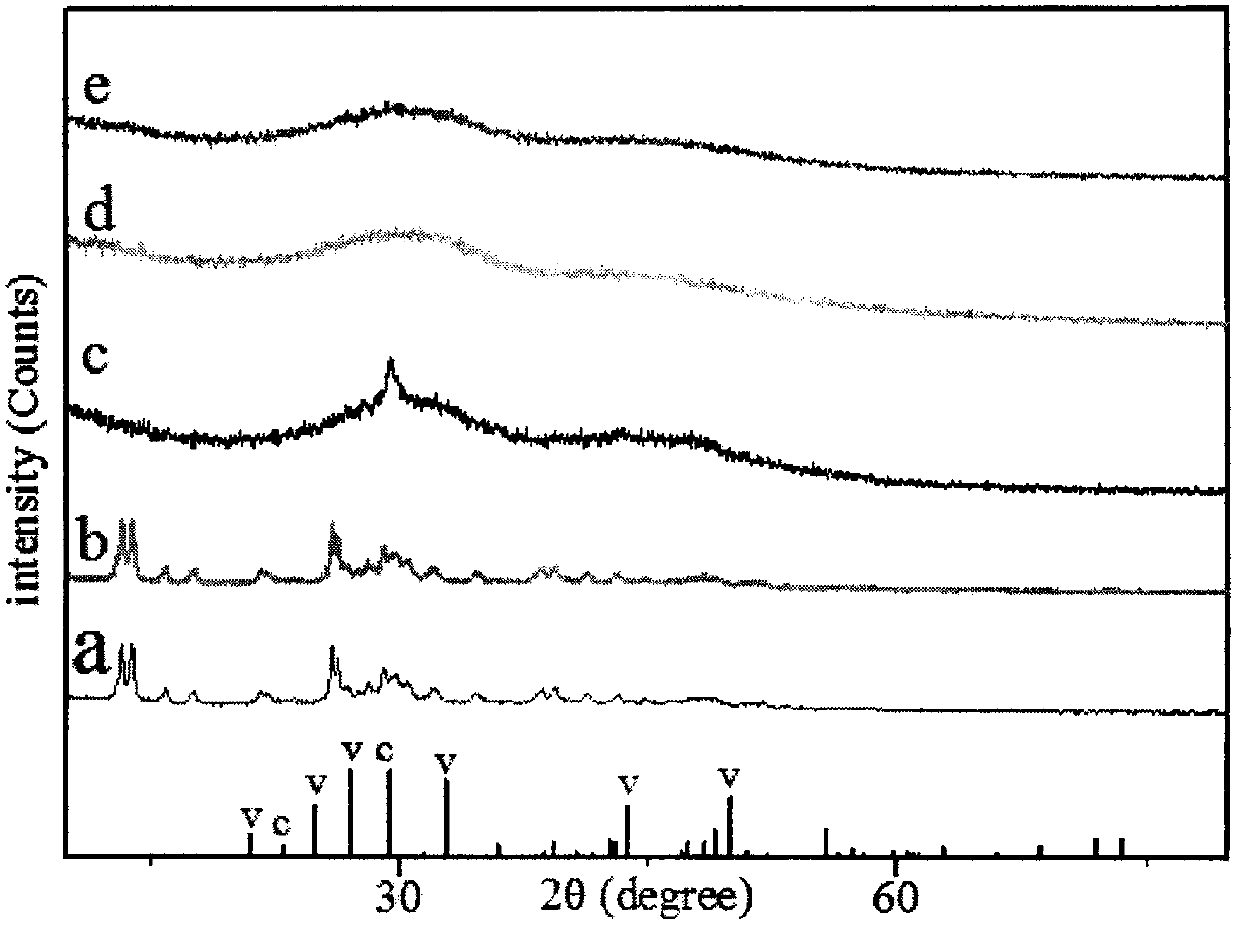

[0063] The products obtained after the ...

Embodiment 3

[0064] Embodiment 3: Taking calcium glycinate as raw material, ethanol and calcium solution volume ratio is 3: 1, calcium ion and ion molar ratio is 5: 1, prepares amorphous calcium carbonate under the condition of different aging time

[0065] Use a 50mL graduated cylinder to measure 30mL of absolute ethanol in a three-necked flask, then add 10mL of 1mol / L calcium glycinate solution to the flask, and then add 2mL of 1mol / L MgCl to the solution 2 solution, so that the molar ratio of calcium ions and magnesium ions in the solution is 5:1. Stir and pass CO directly 2 , until the pH value of the solution was 8, stop feeding CO 2 . Sampling was carried out when the aging time was 0h, 1h, 2h, 3h, and 4h, and the obtained calcium carbonate slurry was suction-filtered, washed with absolute ethanol or a mixture of alcohol and water, and the obtained calcium carbonate was stored in a vacuum oven at 60°C. Dry in medium for 24h to get the product.

[0066] The products obtained after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com