Preparation method and application of waterborne automotive coating material with self-repairing function

A moisture and reaction technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of destroying the high decoration and gloss of the surface, shortening the service life of the coating film, and reducing the mechanical strength of the coating film, so as to improve the toughness and mechanical strength of the coating. Performance, extended service life, and improved leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

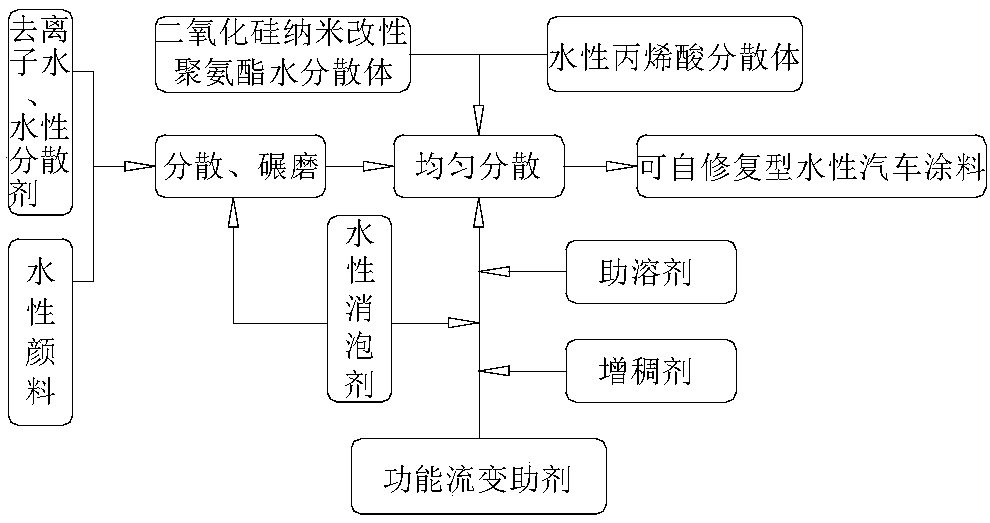

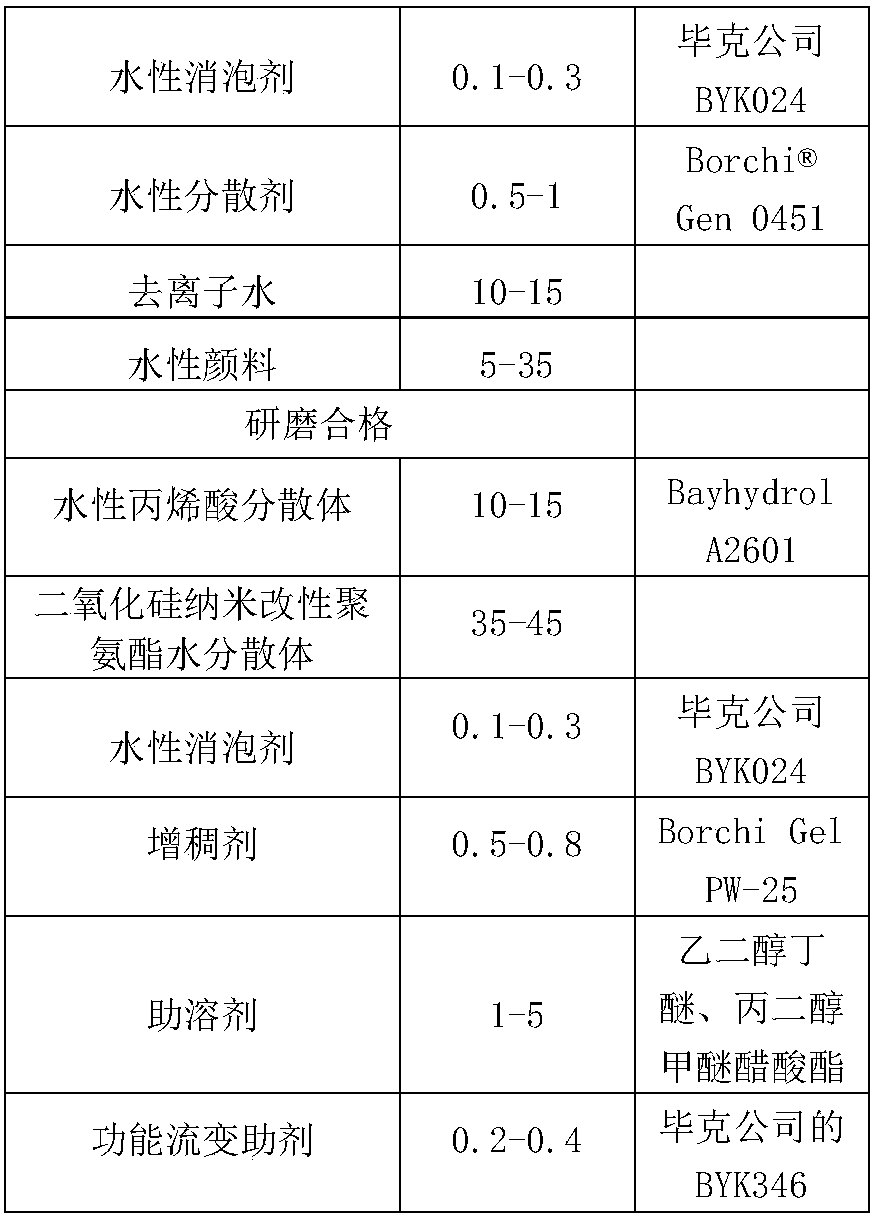

Method used

Image

Examples

Embodiment 1

[0022] In a reactor equipped with a stirring paddle, a thermometer and a condenser, add 70 parts by weight of polyethylene glycol, 9 parts by weight of N-methylpyrrolidone, and 0.3 parts by weight of nano-silicon dioxide, and raise the temperature to 80°C under nitrogen protection. After maintaining the high-speed dispersion state for 0.5h, add 4.5 parts by weight of dimethylolbutyric acid, cool down to 65°C, add 0.03 parts by weight of dibutyltin dilaurate and 20 parts by weight of isophorone diisocyanate, keep the temperature at 80°C, and continue React for 3.5 hours, cool to 55° C., add 3 parts by weight of triethylamine for neutralization, and react for 25 minutes until the pH value is 8-9 to obtain a nano-modified polyurethane aqueous dispersion prepolymer.

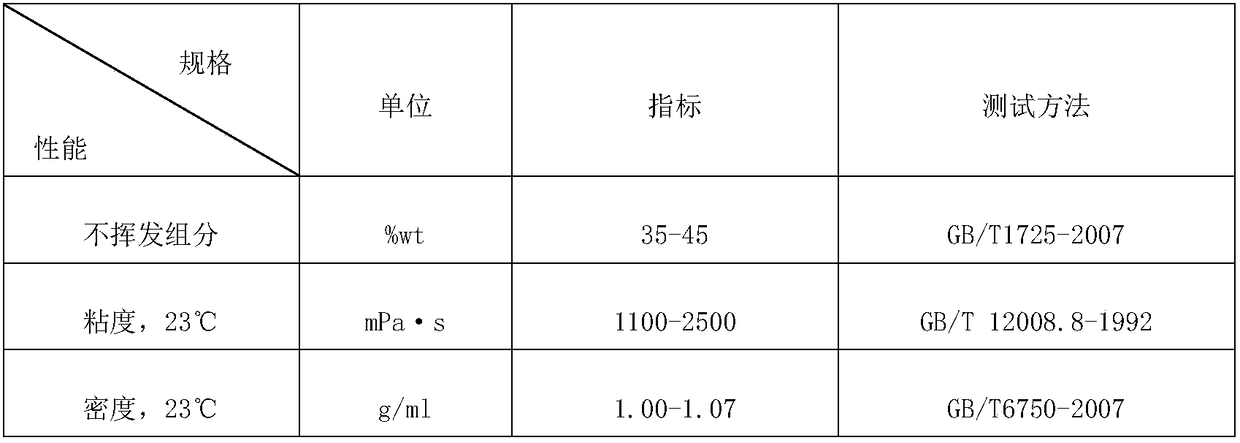

[0023] Keep the prepolymer at 70°C, vigorously stir and slowly add it to deionized water at 25°C, and finally add an appropriate amount of ethylenediamine, react for 2 hours, and then discharge, to obtain a silica nan...

Embodiment 2

[0025] Embodiment 2 performance indicator test method is the same as embodiment 1

[0026] In stirring paddle, thermometer, condenser reactor, add 60 parts by weight polyalcohol (polyethylene glycol, polypropylene glycol or polycarbonate glycol, polybutylene adipate glycol), 5 Parts by weight of N-methylpyrrolidone and 0.1 parts by weight of nano-silica, under the protection of nitrogen, the temperature was raised to 80°C, and after maintaining a high-speed dispersion state for 0.5h, 3 parts by weight of dimethylolbutyric acid was added, and the temperature was lowered to 65°C. Add 0.02 parts by weight of organic tin catalyst (dibutyltin dilaurate, stannous octoate) and 15 parts by weight of polyisocyanate (isophorone diisocyanate or diphenylmethane diisocyanate or hexamethylene diisocyanate), keep the temperature at 80 ℃, continue to react for 3 minutes, cool to 55℃, add 2 parts by weight of neutralizing agent (ammonia or triethylamine or dimethylethanolamine) for neutralizat...

Embodiment 3

[0028] Embodiment 3 performance indicator test method is the same as embodiment 1

[0029] In stirring paddle, thermometer, condenser reactor are housed, add 80 parts by weight polyalcohols (polyethylene glycol, polypropylene glycol or polycarbonate glycol, polybutylene adipate glycol), 10 Parts by weight of N-methylpyrrolidone and 0.5 parts by weight of nano-silica, under the protection of nitrogen, the temperature was raised to 80°C, and after maintaining a high-speed dispersion state for 0.5h, 5 parts by weight of dimethylolbutyric acid was added, and the temperature was lowered to 65°C. Add 0.05 parts by weight of organic tin catalyst (dibutyltin dilaurate, stannous octoate) and 25 parts by weight of polyisocyanate (isophorone diisocyanate or diphenylmethane diisocyanate or hexamethylene diisocyanate), keep the temperature at 80 ℃, continue to react for 4 hours, cool to 55 ℃, add 4 parts by weight of neutralizing agent (ammonia or triethylamine or dimethylethanolamine) for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com